View here

View here

The UK energy sector is changing rapidly. The boundaries between users, suppliers and generators are blurring as energy users are choosing to generate their own energy and are managing their energy use more proactively while, conversely, generators are increasingly seeing users as potential sources of generation and providers of demand management.

“The UK is undergoing an unprecedented energy revolution with electricity at its heart – a transition to a low-carbon society requiring new energy solutions for power generation, heating, transport and the wider economy”

In that context, our Group’s purpose is to help change the way energy is generated, supplied and used for a better future. This means that sustainability, in its broadest sense, must be at the very core of what we do. Successful delivery of our purpose depends on all our people, across all our businesses, doing the right thing, every day. With the right products and services, we can go even further and help our customers make the right, sustainable energy choices.

As our businesses transform and we embrace a larger customer base, different generation technologies and operate internationally, the range of sustainability issues we face is widening and becoming more complex. At the same time, the range of stakeholders looking to Drax for responsible leadership on sustainability is increasing. The need for transparency is greater than ever, so our website’s sustainability section provides a comprehensive insight into the Group’s environmental, social and governance management and performance during 2017.

We initiated a process which would allow us to participate in the United Nations Global Compact (UNGC). We are committed to the initiative and its ten principles, which align with our culture of doing the right thing.

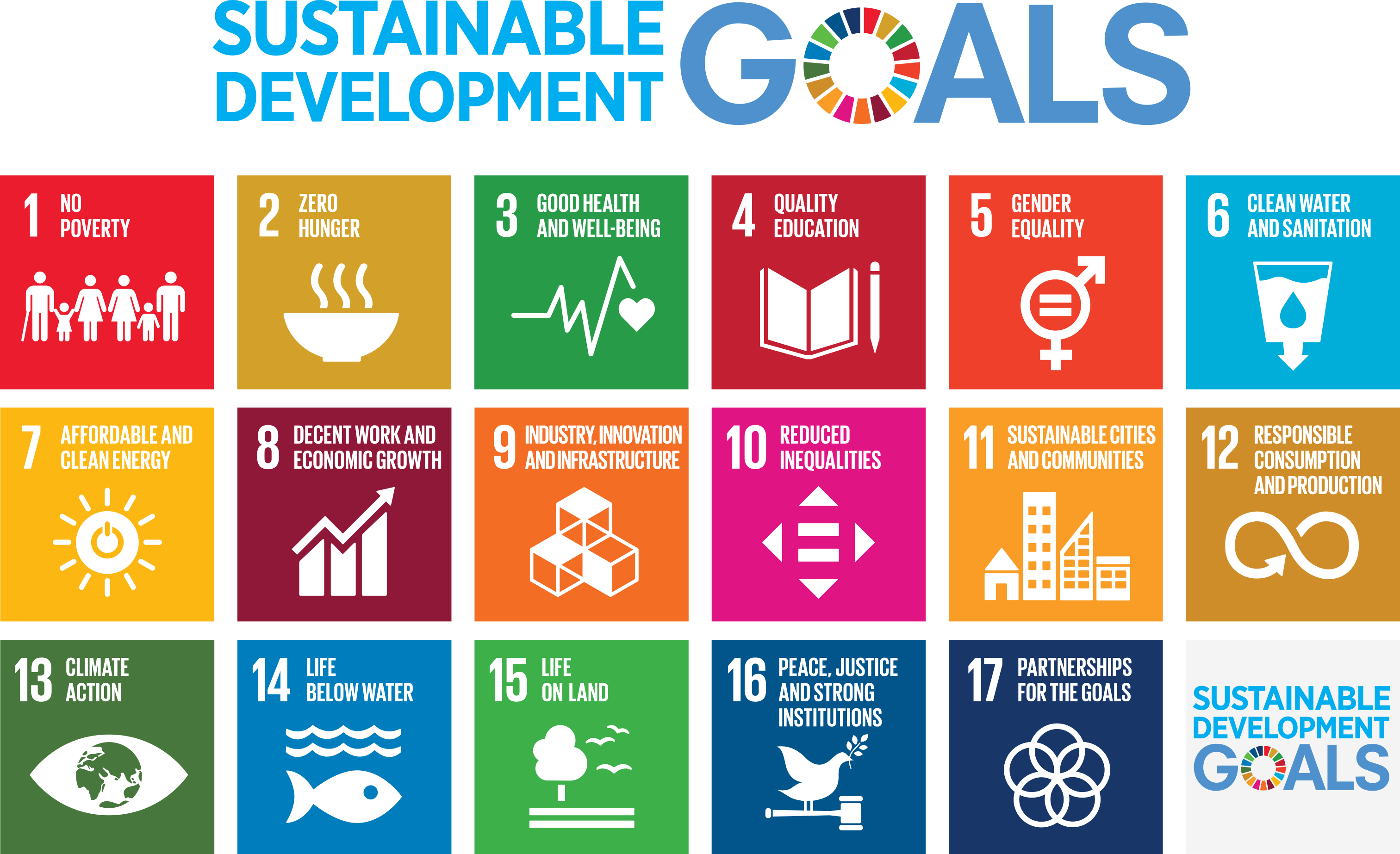

Our website’s sustainability section also sets out our commitment to achieving the United Nations’ Sustainable Development Goals through our operations, the services we deliver to our customers and in partnership with others.

Our website’s sustainability section also sets out our commitment to achieving the United Nations’ Sustainable Development Goals through our operations, the services we deliver to our customers and in partnership with others.

Global ambitions and goals are important, but so too are our ambitions for our local and regional communities. As such, we have played a key role in the UK Northern Powerhouse Partnership, initiatives such as POWERful Women and a comprehensive programme of stakeholder engagement.

“Sustainability, in its broadest sense, must be at the very core of what we do”

Finally, I do not believe any organisation, however well intentioned, can get its commitment to sustainability perfect on its own and I am very keen for Drax to learn from people reading our website’s sustainability section. It sets out what we see as our achievements and aspects in which we believe we need to do better. I would like to invite any stakeholder with an interest to comment on what we’re doing and help us improve where we can. Feedback can be submitted at Contact us or via our Twitter account or Facebook page.

Finally, I do not believe any organisation, however well intentioned, can get its commitment to sustainability perfect on its own and I am very keen for Drax to learn from people reading our website’s sustainability section. It sets out what we see as our achievements and aspects in which we believe we need to do better. I would like to invite any stakeholder with an interest to comment on what we’re doing and help us improve where we can. Feedback can be submitted at Contact us or via our Twitter account or Facebook page.

Read the Chief Executive’s Review in the Drax Group plc annual report and accounts

In 2015, the United Nations launched 17 Sustainable Development Goals (SDGs) to end poverty, protect the planet and ensure prosperity for all by 2030. At Drax, improved performance has guided our business purpose for over four decades. We are committed to play our part in achieving the UN SDGs through our operations, the services we deliver to our customers and in partnership with others.

We provide 6% of the UK’s electricity and play a vital role in helping change the way energy is generated, supplied and used as the UK moves to a low-carbon future. In 2017, 65% of the electricity we produced came from biomass, rather than coal. Our B2B Energy Supply businesses encourage customers to be more sustainable, including through the provision of reliable, renewable electricity at no premium compared to fossil fuel-generated electricity.

We directly employ over 2,500 people in the United Kingdom and United States and their health, safety and wellbeing remains our highest priority. Our B2B Energy Supply business offers energy solutions and value-added services to industrial, corporate and small business customers across the UK.

We develop innovative energy solutions to enable the flexible generation and lower-carbon energy supply needed for a low-carbon future. We also innovate to improve the efficiency of our operations and increase our production capacity, notably in our biomass supply chain. Our B2B Energy Supply business offers “intelligent sustainability” and innovative products and services to our customers.

Our electricity generation activities are a source of carbon emissions. We are committed to helping a low-carbon future by moving away from coal and towards renewable and cleaner fuels, including biomass electricity generation and our planned rapid-response gas plants. We also help our business customers to be more sustainable through the supply of renewable electricity.

We source sustainable biomass for our electricity generation activities and engage proactively with our supply chain to ensure that the forests we source from are responsibly managed. We work closely with our suppliers and through tough screening and audits ensure that we never cause deforestation, forest decline or source from areas officially protected from forestry activities or where endangered species may be harmed.

We engage with stakeholders regularly and build relationships with partners to raise our standards and maximise what can be achieved. Our collaborations align closely with our business, purpose and strategy.

In 2017, we initiated a process which will allow us to participate in the United Nations Global Compact (UNGC) a global sustainability initiative and we will evidence progress next year. We made progress in preparing for participation outlined in the following sections:

We seek to safeguard fundamental human rights for our employees, contractors and anyone that is affected by our business. We ensure that our suppliers apply high standards to protect human rights.

We have policies and standards in place to safeguard our employees and contractors. We respect our employees’ rights in areas such as freedom of association and collective bargaining and we do not tolerate forced, compulsory or child labour. We are committed to providing a safe and healthy workplace for all our people and we strive to prevent discrimination and promote diversity in our workforce.

As a generator and supplier of electricity, we take our responsibility to protect the environment very seriously. We have transformed our generation business and are seeking to further reduce our environmental impact. We focus on reducing our emissions to air, discharges to water, disposal of waste, and on protecting biodiversity and using natural resources responsibly. We have invested heavily in lower-carbon technology as we continue to transition away from coal to renewable and lower-carbon fuels.

We do not tolerate any forms of bribery, corruption or improper business conduct. Our “Doing the Right Thing” framework sets out the ethical principles our people must uphold, which is supported by the Group corporate crime policy. Our strict ethical business principles apply to all employees and contractors and we expect the same high standards from anyone we do business with.

It was no surprise when President Donald Trump echoed his election campaign stance and announced his intention to renegotiate – or failing that withdraw the US – from the Paris Agreement on Climate Change. It raised the question, would other countries back away from their own climate change targets?

In fact, many reaffirmed their commitment to the pact and continue their progress towards becoming low carbon economies. For those in the European Union, this means meeting the 2030 climate and energy framework, which sets three key targets for member states: cut greenhouse gas (GHG) emissions by at least 40% from 1990 levels, produce at least 27% of their energy through renewable sources, and improve energy efficiency by at least 27%.

Many countries across Europe, however, have set climate objectives that go beyond these. Whether they can meet those goals is another matter.

The Portuguese government has pressed the EU to go further than its 2030 targets and is aiming for 40% of total energy consumption to come from renewables by 2030. This target is part of its Green Growth Commitment 2030, which also sets out to create more green – or low carbon economy – jobs and improve overall energy efficiency across the country.

Portugal has rapidly increased its renewable energy production by investing in wind (mainly onshore) and hydro power, although it is rapidly developing its solar capabilities. It is also looking at small scale renewable energy generation through wave, thermal and biomass power.

Portugal has two operational coal plants that together are responsible for 16% of the country’s carbon emissions. However, the government is seeking to phase these out prior to 2025.

The growth in renewable energy within the power industry specifically has been a big success story for Portugal. In 2005, renewables accounted for only 16% of total electricity production – by 2015 they produced an average of 52%.

The country made headlines in May 2016 for running on 100% renewable electricity for four days in a row. Unsurprisingly, this means the government is confident of achieving a target of 31% renewables in gross final energy consumption by 2020, which would mean 57.4% renewable electricity generation.

Germany set its current climate targets as far back as 2007. It subsequently agreed to the Paris Agreement and the EU’s 2014 climate and energy framework.

Added to this, the country has its own ambitious aims for 2050: cut GHG emissions by up to 95% compared to 1990 levels (with an interim target of 40% by 2020), increase the share of renewables in gross final energy consumption to 60%, and increase all electricity generated from renewables to 80%.

Germany’s Climate Action Programme 2020 and Climate Action Plan 2050, set out its plans for reducing GHG emissions. Much of this is based around the Energiewende (energy transition), a strategy that will see the country phase-out nuclear power and decarbonise the economy through renewable energy initiatives.

According to these plans, Germany’s energy supply must be almost completely decarbonised by 2050, with coal power slowly phased out and replaced with renewables, especially wind power. The utilisation of biomass will be limited and sourced mostly from waste. It also stresses the role of the European Union Emission Trading System to meet targets.

Between 1990 and 2015, emissions reduced by 27%. In 2015, the share of renewable sources in German domestic power consumption amounted to 31.6%.

However, German energy-related CO₂ emissions rose almost 1% in 2016, despite a fall in coal use and the ongoing expansion of renewable energy sources. This rise is due in part to an overall increase in energy consumption and an increase in natural gas use and diesel for electricity, heat and transport.

Projections from the environment ministry in September 2016 indicated that Germany will likely miss its 2020 climate target.

Alongside its EU and Paris commitments, the UK Houses of Parliament approved the Climate Change Act in 2008, which commits to reducing GHG emissions by at least 80% of 1990 levels by 2050.

The Act requires the government to set legally-binding carbon budgets, a cap on the amount of GHG emitted in the UK over a five-year period. The first five carbon budgets have been put into legislation and will run up to 2032. These include reducing emissions 37% below 1990 levels by 2020 and 57% by 2030.

A key milestone in the UK’s decarbonisation is to entirely phase out coal by 2025, which will mean either closing or converting (as in the case of Drax Power Station) existing coal power stations.

Under its legally binding carbon budget system, every tonne of GHG emitted between now and 2050 will count. Where emissions rise in one sector of the economy (be it agriculture, heavy industry, power, transport, etc.), the UK must achieve corresponding falls in another.

The UK’s initial focus has been to transition to renewable electricity production. Wind, biomass and solar power have all grown significantly, aided by government support, and by initiatives like the carbon price floor.

The UK’s progress towards its targets is positive, but leaves room for improvement. Renewables generated 14.9% of the UK’s electricity in 2013. In 2015 they accounted for nearly a quarter of electricity generation and by 2016, low carbon power sources contributed an average of 40% of the UK’s power, with wind generating more power than coal for the first time ever.

The Department for Business, Energy and Industrial Strategy estimates that as of 2016 GHG emissions fell 42% since 1990. Despite this, the Committee on Climate Change (CCC) has said that the government is not on track to meet its pledge of cutting emissions 80% by 2050.

However, it points out the UK is likely to meet the target of making electricity almost entirely low-carbon by early 2030s, but only if further steps are taken such as including increasing investment in more low-carbon generation (such as biomass), and developing carbon capture and storage (CCS) technologies. The UK government is due to publish an emissions reduction plan in the autumn of 2017.

Norway’s climate policy is based on agreements reached in the Storting (the Norwegian Parliament) in 2008 and 2012. They stipulate a commitment to reduce global GHG emissions by at least 30% by 2020 from 1990 levels. The government also approved the goal of achieving carbon neutrality by 2050.

As well as signing the Paris Agreement, Norway has aligned itself with the European Union’s climate target and intends to fulfil its commitment collectively with the EU (of which it is not a member state). This means using the EU emissions trading market, international cooperation on emissions reductions, and project-based cooperation.

Around 98% of Norway’s electricity production already comes from renewable energy sources, mostly through its more than 900 hydropower plants. The remainder is through wind and thermal power.

Norway exports hydropower to the Netherlands and exchanges renewable energy with Denmark, Sweden and Finland. There are plans for similar green exchanges with Germany and the United Kingdom via interconnectors within the next five years.

Norway is also aided by a substantial carbon sink in its forests which cover 30% of its land surface. They sequester (absorb and store) carbon from the atmosphere to such an extent that it equals approximately half of the Scandinavian country’s annual emissions.

While Norway already has one of the world’s most carbon neutral electricity sectors, its significant domestic oil and gas sector means it still struggles to reduce its overall emissions. As such, the government is expected to rely on carbon trading with the EU or international offsets to meet its ambitious goals.

Nonetheless, earlier this year the government said that GHG emissions will fall to around 1990 levels by 2020, although it did not stipulate whether this included buying carbon credits from abroad or not.

Mitigating climate change is a difficult challenge. But it’s one well within the grasp of governments, companies and individuals around the world if we can start thinking strategically.

On the behalf of the German government, The Internal Energy Agency (IEA) and the International Renewable Energy Agency (IRENA) have jointly published a report outlining the long-term targets of a worldwide decarbonisation process, and how those targets can be achieved through long-term investment and policy strategies.

At the heart of the report is a commitment to the ‘66% two degrees Celsius scenario’, which the report defines as, ‘limiting the rise in global mean temperature to two degrees Celsius by 2100 with a probability of 66%’. This is in line with the Paris Agreement, which agreed on limiting global average temperature increase to below two degrees Celsius.

Here are three of the findings from the report that highlight how decarbonisation could change the world.

Decarbonisation will by definition mean reducing the use of carbon-intensive fossil fuels. Today, 81% of the world’s power is generated by fossil fuels. But by 2050, that will need to come down to 39% to meet the 66% two degrees Celsius scenario, according to the report. But, this doesn’t mean all fossil fuels will be treated equally.

Coal will be the most extensively reduced, while other fossil fuels will be less affected. Oil use in 2050 is expected to stand at 45% of today’s levels, but will likely still feature in the energy landscape due its use in industries like petrochemicals.

Gas will likely also remain a key part of the energy makeup, thanks to its ability to provide auxiliary grid functions like frequency response and black-starting in the event of grid failure.

Renewables like biomass will likely play an increasing role here as well, particularly when combined with carbon capture and storage (CCS) technology.

Overall, renewable energy sources will need to increase substantially. In the report’s global roadmap for the future, renewables make up two thirds of the primary energy supply. Reaching this figure will be no mean feat – it will mean renewable growth rates doubling compared with today.

The report highlights the need for ‘end-use’ behaviour to change. This can mean everyday energy users choosing to use a bit less heat, power and fuel for transport in our day-to-day activities, but a bigger driver of change will be by investment in better, more efficient end-use technology – the technology, devices and household appliances we use every day.

In fact, the study argues that net investment in energy supply doesn’t need to increase beyond today’s level – what needs to increase is investment in these technologies. For instance, by 2050, 70% of new cars must be electric cars to meet decarbonisation targets.

Infrastructure design could also be improved for energy efficiency – smart grids, battery storage and buildings retrofitted with energy efficient features such as LED lighting will be essential. There’s also the possibility of increased use of cleaner building materials and processes – for example, constructing large scale buildings out of wood rather than carbon-intensive materials such as concrete and steel.

The upfront costs of meeting temperature targets will be substantial. A case study used in the report estimates that $119 trillion would need to be spent on low-carbon technologies between 2015 and 2050. But it also suggests another $29 trillion may be needed to meet targets.

However, failure to act could mean the world will pay out an even higher figure in healthcare costs, or in other economic costs associated with climate change, such as flood damage or drought. Therefore, the sum for decarbonisation could end up costing between two and six times less than what failing to decarbonise could cost.

On top of this, the new jobs (including those in renewable fuel industries that will replace those lost in fossil fuels) and opportunities that will be created between 2015 and 2050 could add $19 trillion to the global economy. More than that, global GDP could be increased by 0.8% in 2050, thanks to added stimulus from the low carbon economy.

Achieving a cleaner future won’t be easy – it requires planning, effort, and the will to see beyond short-term goals and think about the long-term benefits. But as the report demonstrates, get it right and the results could be considerable.

There is an important difference between carbon dioxide (CO2) emitted from coal (and other fossil fuels) and CO2 emitted from renewable sources. Both do emit CO2 when burnt, but in climate change terms the impact of that CO2 is very different.

To understand this difference, it helps to think small and scale up. It helps to think of your own back garden.

Imagine you are lucky enough to have a garden with space for 30 trees. Three decades ago you decided to plant one tree per year, every year. In this example, each tree grows to maturity over thirty years so today you find yourself with a thriving copse with 30 trees at different stages of growth, ranging from one year to 30 years old.

At 30 years of age, the oldest has now reached maturity and you cut it down – in the spring, of course, before the sap rises – and leave the logs to dry over the summer. You plant a new seedling in its place. Through the summer and autumn the 29 established trees and the new seedling you planted continue to grow, absorbing carbon from the atmosphere to do so.

Winter comes and when it turns cold and dark you burn the seasoned wood to keep warm. Burning it will indeed emit carbon to the atmosphere. However, by end of the winter, the other 29 trees, plus the sapling you planted, will be at exactly the same stage of growth as the previous spring; contain the same amount of wood and hence the same amount of carbon.

As long as you fell and replant one tree every year on a 30-year cycle the atmosphere will see no extra CO2 and you’ll have used the energy captured by their growth to warm your home. Harvesting only what is grown is the essence of sustainable forest management.

If you didn’t have your seasoned, self-supplied wood to burn you might have been forced to burn coal or use more gas to heat your home. Over the course of the same winter these fuels would have emitted carbon to the atmosphere which endlessly accumulates – causing climate change.

Not only does your tree husbandry provide you with an endlessly renewable supply of fuel but you also might enjoy other benefits such as the shelter your trees provide and the diversity of wildlife they attract.

This is a simplified example, but the principles hold true whether your forest contains 30 trees or 300 million – the important point is that with these renewable carbon emissions, provided you take out less wood than is growing and you at least replace the trees you take out, you do not add new carbon to the atmosphere. That is not true with fossil fuels.

It is true that you could have chosen not to have trees. You could instead build a wind turbine or install solar panels on your land. That would be a perfectly reasonable choice but you’ll still need to use the coal at night when the sun doesn’t shine or when the wind isn’t blowing. Worst of all you don’t get all the other benefits of a thriving forest – its seasonal beauty and the habitat that’s maintained for wildlife.

Of course, the wood Drax needs doesn’t grow in our ‘garden’. We bring it many miles from areas where there are large sustainably managed forests and we carefully account for the carbon emissions in the harvesting, processing and transporting the fuel to Drax. That’s why we ‘only’ achieve more than 80% carbon savings compared to coal.