Creating good quality jobs and sustaining Arkansas forests

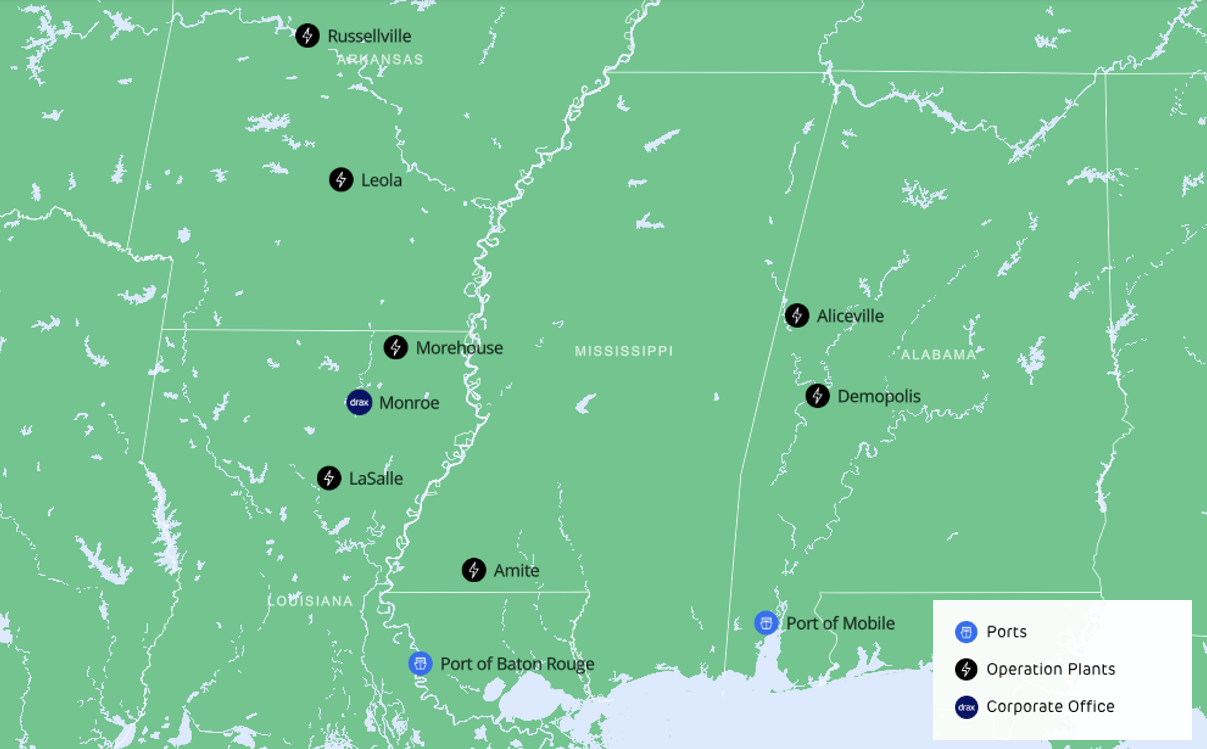

Drax is committed to being a good neighbor. Our investment in Arkansas supports hundreds of jobs in forestry, logging, and trucking, in addition to the hundreds of jobs already created at our two Arkansas pellet mills in Leola and Russellville. In 2023, Drax is projected to provide $31 million in economic impact. We’re also boosting Arkansas’ economy by focusing on jobs, skills, and education.

Our impact

![]()

100’s + of jobs supported across Arkansas

![]()

$31M a year in AR economic impact

![]()

$262k community impact in the US South

Who we are

We’re Future Positive

We recognize that the world is changing – so here at Drax we’re acting now. Our plan is three-fold: people, nature, and climate positive.

We’ve invested $2.5 billion of funding towards enabling these outcomes, with plans to invest an additional $3.7 billion. Underpinning it all we’re using sustainable biomass to deliver people, nature, and climate positive outcomes. Across every part of our ambition for Arkansas, we’re Future Positive.

Our future positive priorities

People Positive

Our people positive plan focuses on providing opportunities and supporting the communities we are a part of through skills and education.

Nature Positive

Our nature positive plan centers on conserving the environment in which Arkansans live, work, and play. We are improving the health and resilience of Arkansas forests by reducing risks from wildfire and pests, while also improving native wildlife habitats.

Climate Positive

Our climate positive plan prioritizes removing carbon from the atmosphere while generating dispatchable, renewable energy to help the USA reach its sustainability goals.

So what is biomass and how does it work?

Biomass, in the form of compressed wood pellets, is a low-carbon replacement for coal that can be used at power stations to generate renewable energy such as electricity and heat. Drax works with landowners across Arkansas to implement best-in-class management practices, enabling them to maximize the benefits that sustainable forest management can deliver.

Frequently Asked Questions

- How is biomass made?

- How does biomass generate power?

- What is sustainable biomass?

- How is Drax ensuring the health of Arkansas forests?

Biomass pellets are made at a pelletisation plant. Here wood that is unsuitable for other industries like sawmill residues, are brought together. The wood is chipped, screened for quality, heated to reduce its moisture content and then converted into a fine powder. This is then pressed through a grate at high pressure to form the solid, short, dense biomass pellet.

Biomass can be produced from different sources including agricultural or forestry residues, dedicated energy crops or waste products such as uneaten food. Drax Power Station uses compressed wood pellets sourced from sustainably managed working forests in the US, Canada, Europe and Brazil, and are largely made up of low-grade wood produced as a byproduct of the production and processing of higher value wood products, like lumber and furniture. Biomass producers and users must meet a range of stringent measures for their biomass to be certified as sustainable and responsibly sourced. Areas Drax sources its pellets from January 2021 to December 2021 include USA (64.9%), Canada (15.5%), Latvia (9.3%), Estonia (2.8%), Brazil (2.5%), Portugal (2.4%), Belarus (1.4%)*, UK (0.7%). Russia (0.4%)*, and other European countries (0.1%).

Biomass pellets can be used to generate power in a similar way to coal, allowing existing coal power stations to be transformed to use renewable bioenergy instead. A conveyor system takes pellets from storage through to pulverising mills, where they are crushed into a fine powder that is then blown into the power station’s boiler. Here the biomass is combusted as fuel, the heat from this combustion is used to make steam which powers the generators that produce electricity. Biomass pellets’ density and uniform shape also makes them easier to transport and store in large quantities.

Sustainable biomass is made of the low grade and low quality by-products from the forestry industry that don’t negatively impact the growth of the forest, the amount of carbon being stored, biodiversity and the socioeconomic wellbeing of the communities that surround them. When used for heat and power, sustainable biomass releases significantly less carbon dioxide than fossil fuels. Using forestry residues from harvesting also helps reduce the risk of forest fires, pests and disease outbreaks. This ensures that forests will not be negatively affected by the cultivation of biomass, instead the removal of waste and low-grade wood promotes healthy biodiversity and growth.

Drax ensures the health of Arkansas forests through sustainable forestry. Biomass pellets are created using low-grade wood waste, tree trimmings, and residue from local wood processing plants. Drax also implements the practices of reforestation and afforestion.

Biomass pellets are made at a pelletisation plant. Here wood that is unsuitable for other industries like sawmill residues, are brought together. The wood is chipped, screened for quality, heated to reduce its moisture content and then converted into a fine powder. This is then pressed through a grate at high pressure to form the solid, short, dense biomass pellet.

Biomass can be produced from different sources including agricultural or forestry residues, dedicated energy crops or waste products such as uneaten food. Drax Power Station uses compressed wood pellets sourced from sustainably managed working forests in the US, Canada, Europe and Brazil, and are largely made up of low-grade wood produced as a byproduct of the production and processing of higher value wood products, like lumber and furniture. Biomass producers and users must meet a range of stringent measures for their biomass to be certified as sustainable and responsibly sourced. Areas Drax sources its pellets from January 2021 to December 2021 include USA (64.9%), Canada (15.5%), Latvia (9.3%), Estonia (2.8%), Brazil (2.5%), Portugal (2.4%), Belarus (1.4%)*, UK (0.7%). Russia (0.4%)*, and other European countries (0.1%).

View MoreBiomass pellets can be used to generate power in a similar way to coal, allowing existing coal power stations to be transformed to use renewable bioenergy instead. A conveyor system takes pellets from storage through to pulverising mills, where they are crushed into a fine powder that is then blown into the power station’s boiler. Here the biomass is combusted as fuel, the heat from this combustion is used to make steam which powers the generators that produce electricity. Biomass pellets’ density and uniform shape also makes them easier to transport and store in large quantities.

View MoreSustainable biomass is made of the low grade and low quality by-products from the forestry industry that don’t negatively impact the growth of the forest, the amount of carbon being stored, biodiversity and the socioeconomic wellbeing of the communities that surround them. When used for heat and power, sustainable biomass releases significantly less carbon dioxide than fossil fuels. Using forestry residues from harvesting also helps reduce the risk of forest fires, pests and disease outbreaks. This ensures that forests will not be negatively affected by the cultivation of biomass, instead the removal of waste and low-grade wood promotes healthy biodiversity and growth.

View MoreDrax ensures the health of Arkansas forests through sustainable forestry. Biomass pellets are created using low-grade wood waste, tree trimmings, and residue from local wood processing plants. Drax also implements the practices of reforestation and afforestion.

View More