- The rail link has increased capacity to deliver more sustainable biomass from Drax’s LaSalle BioEnergy pellet plant in Louisiana, USA to its UK power station, taking thousands of trucks off local roads

- The $15 million rail link and other initiatives have already contributed to a $5/tonne reduction in Drax’s biomass production costs in 2019

In its first year of operation, a new $15m rail link has increased the flow of sustainable biomass from one of Drax Group’s US pellet plants to its UK power station, reducing emissions and costs whilst increasing the resilience of the energy company’s supply chain.

The first train arrives at the LaSalle plant in May 2019. By Rafael Moreno

The five miles of rail track connects Drax’s LaSalle pellet plant in northern Louisiana to the regional rail network, enabling freight trains to deliver the pellets to the company’s dedicated export facility at the Port of Greater Baton Rouge.

From there, the pellets are shipped to Drax Power Station in North Yorkshire, which supplies around 12% of the UK’s renewable electricity.

The new rail link allows Drax to deliver around 7,000 tonnes of sustainable biomass to the Port of Greater Baton Rouge in each train, compared to just 27 tonnes that could be transported by each truck previously.

Drax Biomass Senior Vice President Matt White said:

“The new rail spur has been a great success. Since it was commissioned last May it has significantly increased the amount of sustainable biomass we can deliver. It’s also taken thousands of trucks off local roads, unlocking carbon savings and costs in our supply chain as we build a long-term future for the sustainable biomass that provides millions of UK homes and businesses with renewable power.

“Biomass-generated electricity will be an important part of the global climate change solution. It supports healthy forest growth and biodiversity, while providing reliable, flexible renewable power, and could enable bioenergy with carbon capture and storage, known as BECCS – a vital negative emissions technology that will be crucial to meeting net zero targets.”

A team of up to 40 contractors worked through two of the wettest Louisiana winters in decades to clear the site, excavating around 180,000 cubic yards of dirt to level off the ground and stabilise it before three sets of rail tracks could be laid. The work also included installing conveyors to get the pellets to the new rail loading point.

Rafael Moreno, Drax Biomass associate director of engineering said:

“It was a huge amount of work and the wet winters certainly created some challenges. It’s hard to excavate when everything turns into mud. But the team pulled together and worked through the night to get the track laid and completed so the spur could be commissioned in May last year.”

The rail spur at LaSalle is part of Drax’s wider efforts to cut the costs of its biomass by around a third by 2027. The rail link and other initiatives, including the co-location of a sawmill at the LaSalle site last year, has already contributed to a 3% reduction in biomass production costs to $161/tonne in 2019 compared with $166/tonne in 2018.

Drax acquired the LaSalle BioEnergy plant in Urania in northern Louisiana in 2017. LaSalle BioEnergy is one of three US pellet plants owned by Drax. The three plants produce a total of 1.5 million tonnes of sustainable biomass pellets a year.

ENDS

Picture captions:

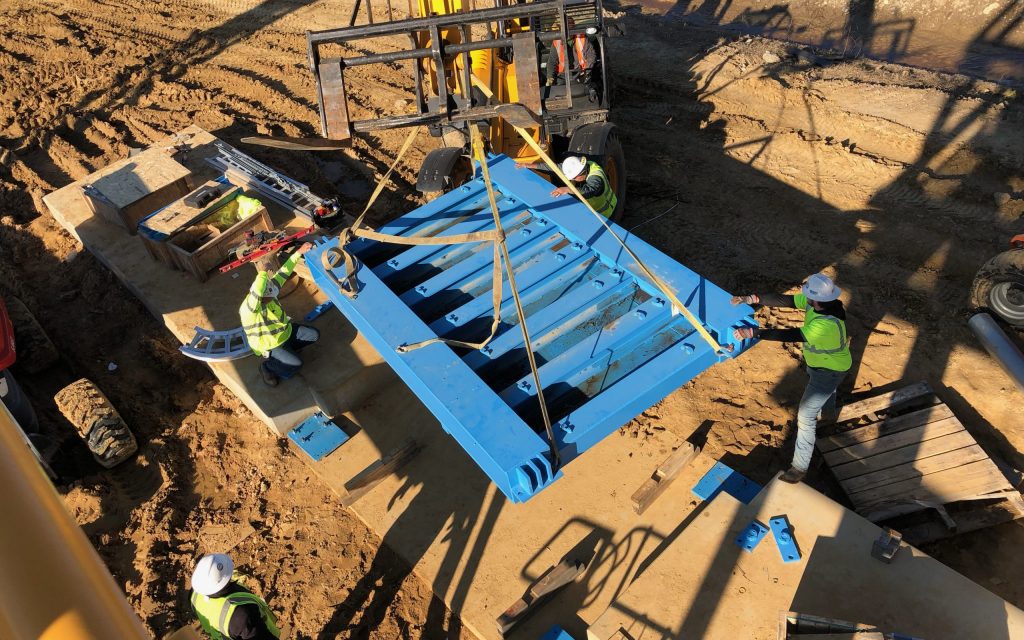

- Installing the scales in January 2019 to weigh the pellets loaded onto each railcar. By Rafael Moreno [View/download].

- The first train arrives at the LaSalle plant in May 2019. By Rafael Moreno [View/download].

Virtual tours:

360 tour of LaSalle: view here and pictured below. Works best on Chrome and Firefox browsers. Good internet connection required.

- Sawmill residue pile

- Rail loading

- Rail spur

Video tour of LaSalle: watch here or below.

Media contacts:

Annmarie Sartor

Drax Biomass Communications Officer

E: annmarie.sartor@draxbiomass.com

T: +1 318-801-0046

Selina Williams

Drax Group Media Manager

E: selina.williams@drax.com

T: +44 7912 230393

Editor’s Notes:

- Cost reduction projects at Drax’s US operations include:

- Co-location of a sawmill, constructed by Hunt Forest Products in 2019, next to the LaSalle pellet plant. The sawmill, which began production in February last year, supplies sawmill residues, such as sawdust, to Drax. This helps lower processing costs to produce pellets and delivers the greatest carbon savings. It also reduces transportation costs.

- Further operational efficiencies to come this year include the full commissioning of a rail logistics facility, known as a rail chambering yard, at the Port of Greater Baton Rouge. This allows multiple trains to arrive at the port at the same time, reducing congestion at the pellet plants.

- By 2022, these and other initiatives are expected to reduce the cost of Drax’s self-supplied biomass by $35/tonne compared to 2018 costs.

- Sustainable biomass is an important part of the UK’s long-term energy mix. Using sustainable biomass at Drax Power Station has already delivered carbon savings of more than 80% and made Drax Europe’s largest decarbonisation project.

About Drax

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030.

Its 2,900-strong employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

Customers:

Through its two B2B energy supply brands, Haven Power and Opus Energy, Drax supplies energy to 250,000 businesses across England, Scotland and Wales.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com