Thank you very much Nick, it’s a pleasure to be here in Madrid. My name is Will Gardiner and I am the CEO of the Drax Group. We have been proud members of the Powering Past Coal Alliance for a year now, but our journey beyond coal began more than a decade ago, when we realised that we had a responsibility to our communities, our shareholders and our colleagues to be part of the solution to the escalating climate crisis.

And so at Drax we did something that many believed wasn’t possible and began to replace coal generation with sustainable, renewable biomass.

With the right support and commitment from successive UK ministers, and through the ingenuity of our people, within a decade we transformed into Europe’s largest decarbonisation project and its biggest source of renewable power – generating 12% of the UK’s renewable electricity last year while reducing our carbon emissions by more than 80% since 2012.

We have reduced our emissions, we believe, more than any other energy company in the world and we have enabled a just transition for thousands of UK workers who began their career in coal but will end it by producing renewable, flexible and low carbon power for 13 million British homes.

But as the climate crisis intensifies and the clock counts down, we can’t stand still. So today I am pleased to share our new ambition: to move beyond carbon neutrality, to achieve something that nobody has before, and become the world’s first carbon negative company by 2030.

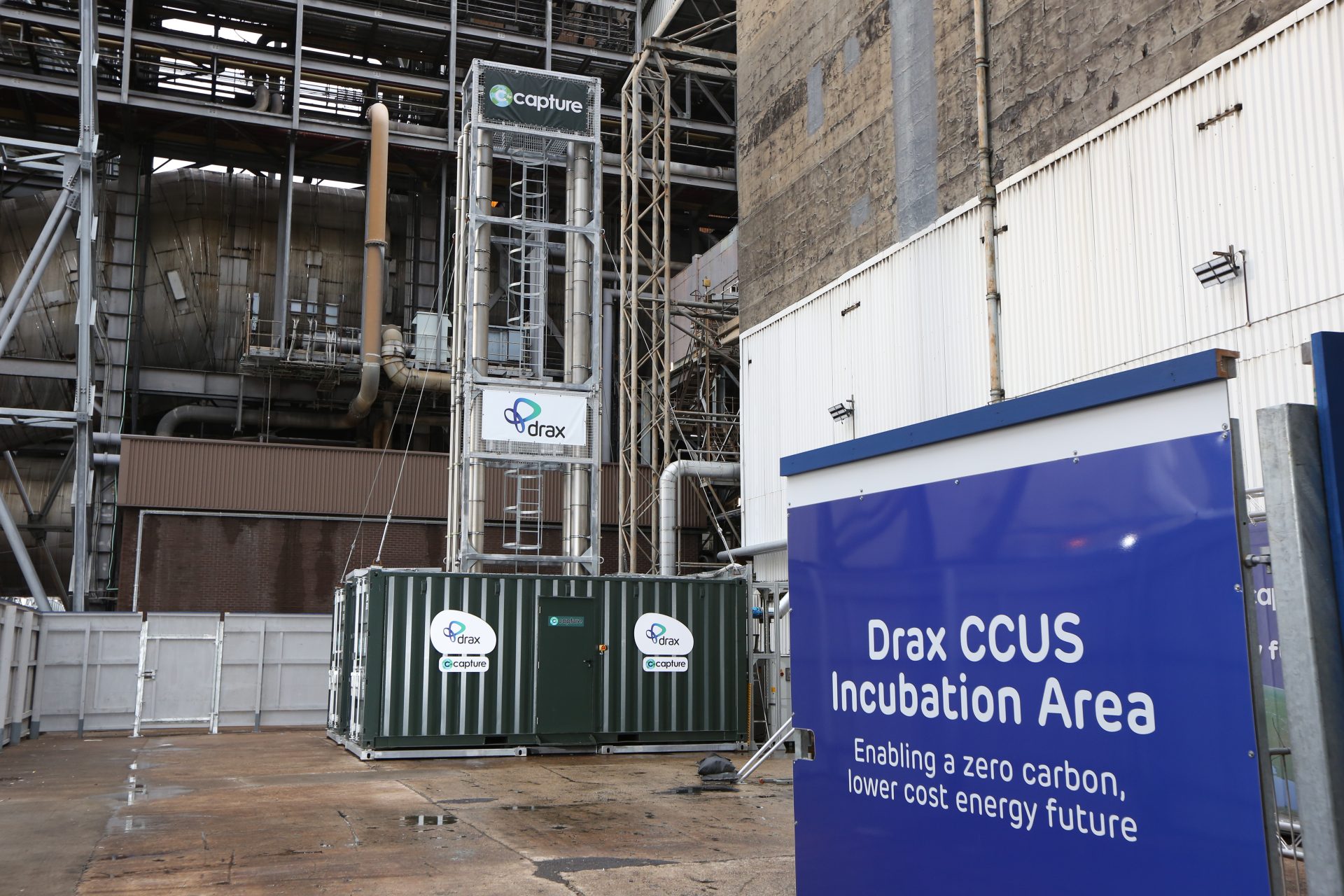

By applying carbon capture and storage technology to our bioenergy generation we can become the first company in the world to remove more carbon dioxide from the atmosphere than we produce, while continuing to produce about 5% of the UK’s overall electricity needs.

As the IPCC and UK government’s Committee on Climate Change make clear – negative emissions are vital if we are to limit the earth’s temperature rise to 1.5 degrees.

At Drax we can be the first company to produce negative emissions at scale, helping to arrest climate change and redefining what is possible in the transition beyond coal.

If we are to defeat the climate crisis we must do it in a way that unlocks jobs and economic growth, unleashes entrepreneurial spirit and leaves nobody behind. The UK is unrivalled in decarbonising in this way. We are second to none in deploying renewables like offshore wind and bioenergy, which have transformed lives and our post-industrial communities.

We need to apply a similar framework to Bioenergy with Carbon Capture and Storage as made offshore wind so successful. Fundamentally, an effective strategic partnership of government and the private sector was critical. The government provided support and an effective carbon tax regime. With confidence in that regulatory framework, many businesses provided investment and innovation. As a result, offshore wind has grown from less than 600 megawatts (MW) of installed capacity in 2008 to more than 8,000 MW in 2018 — an increase of more than 13 times in 10 years to produce 7.5% of the UK’s electricity.

At the same time, the cost of that electricity has declined from £114/MWh in 2015 to £39/MWh in 2019, the latter being a cost that will make offshore wind viable without subsidy. With government support and an effective regulatory regime to give the private sector the confidence to invest and innovate, bioenergy with carbon capture and storage will trace that same path. At the same time, investing in this technology will both save lots of existing jobs and create many next generation green technology jobs.

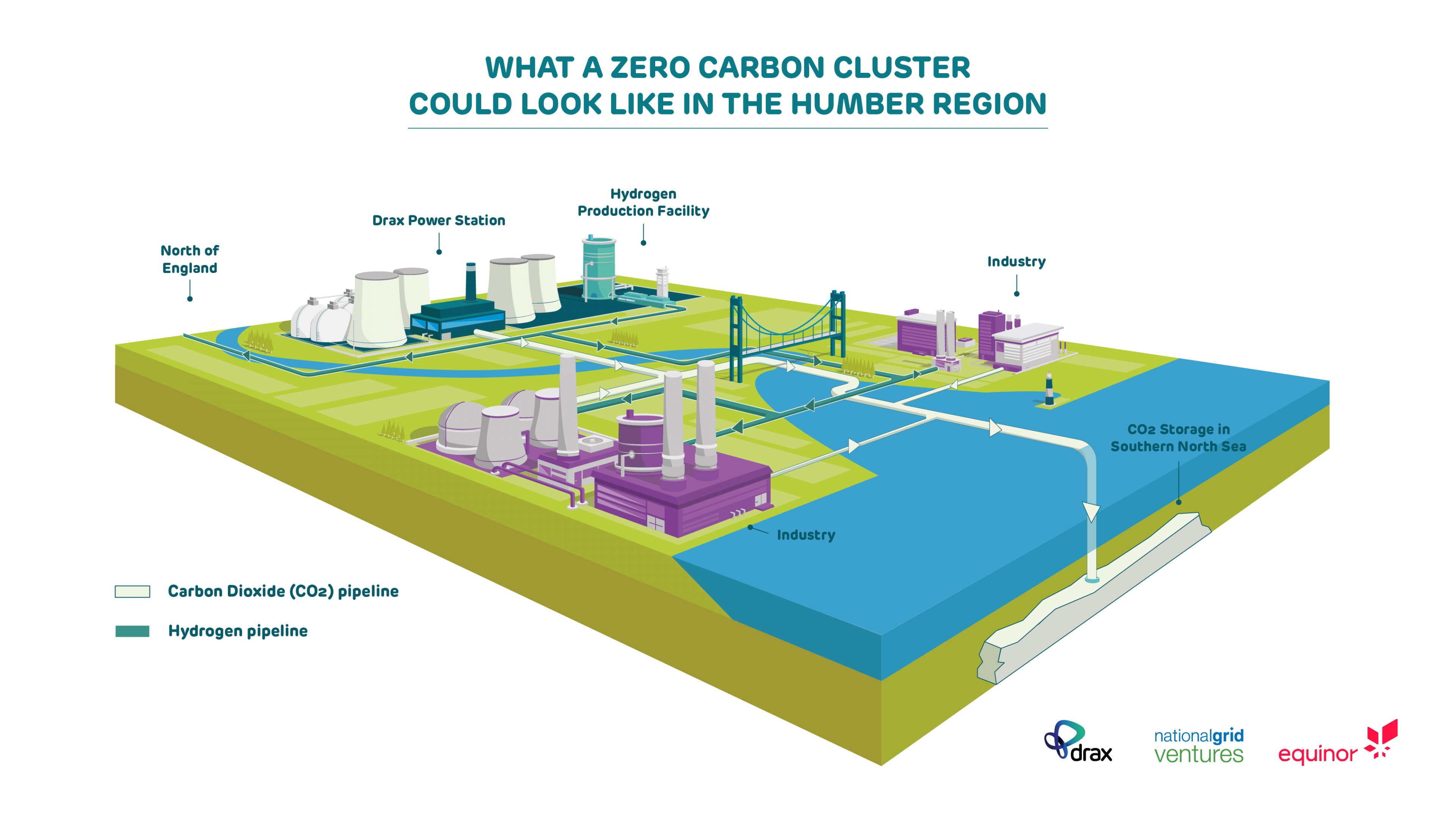

That is why we have founded, along with Equinor and National Grid, Zero Carbon Humber, to work with the government to bring carbon capture and storage infrastructure to the northeast of the UK. We can save 55,000 existing heavy industry jobs, while capturing as much as 30 million tons of CO2 per year. At the same time we will create a new industry and also the infrastructure for a new hydrogen economy to take our decarbonisation further.

By creating the right conditions for bioenergy with carbon capture and storage to flourish, Britain can continue to benefit – socially, economically and environmentally from being at the vanguard of the fight against climate change.

And at the same time, it is our ambition at Drax to play a major role in that fight by becoming the first carbon negative company.

Thank you

Read the press release: Drax sets world-first ambition to become carbon negative by 2030

Photo caption: Will Gardiner at Powering Past Coal Alliance event in the UK Pavilion at COP25 in Madrid. Click to view/download.

Drax is the first company in the world to announce an ambition to be carbon negative by 2030 and we are confident we can achieve it – pioneering new technology is what we do best. #carbonnegative #COP25

Find out more ➡️ https://t.co/pwIkO2jTfF pic.twitter.com/nWl6bFwcip— Drax (@DraxGroup) December 10, 2019

Learn more about carbon capture, usage and storage in our series:

- Planting, sinking, extracting – some of the ways to absorb carbon from the atmosphere

- From capture methods to storage and use across three continents, these companies are showing promising results for CCUS

- Why experts think bioenergy with carbon capture and storage will be an essential part of the energy system

- The science of safely and permanently putting carbon in the ground

- The numbers must add up to enable negative emissions in a zero carbon future, says Drax Group CEO Will Gardiner.

- The power industry is leading the charge in carbon capture and storage but where else could the technology make a difference to global emissions?

- From NASA to carbon capture, chemical reactions could have a big future in electricity

- A roadmap for the world’s first zero carbon industrial cluster: protecting and creating jobs, fighting climate change, competing on the world stage

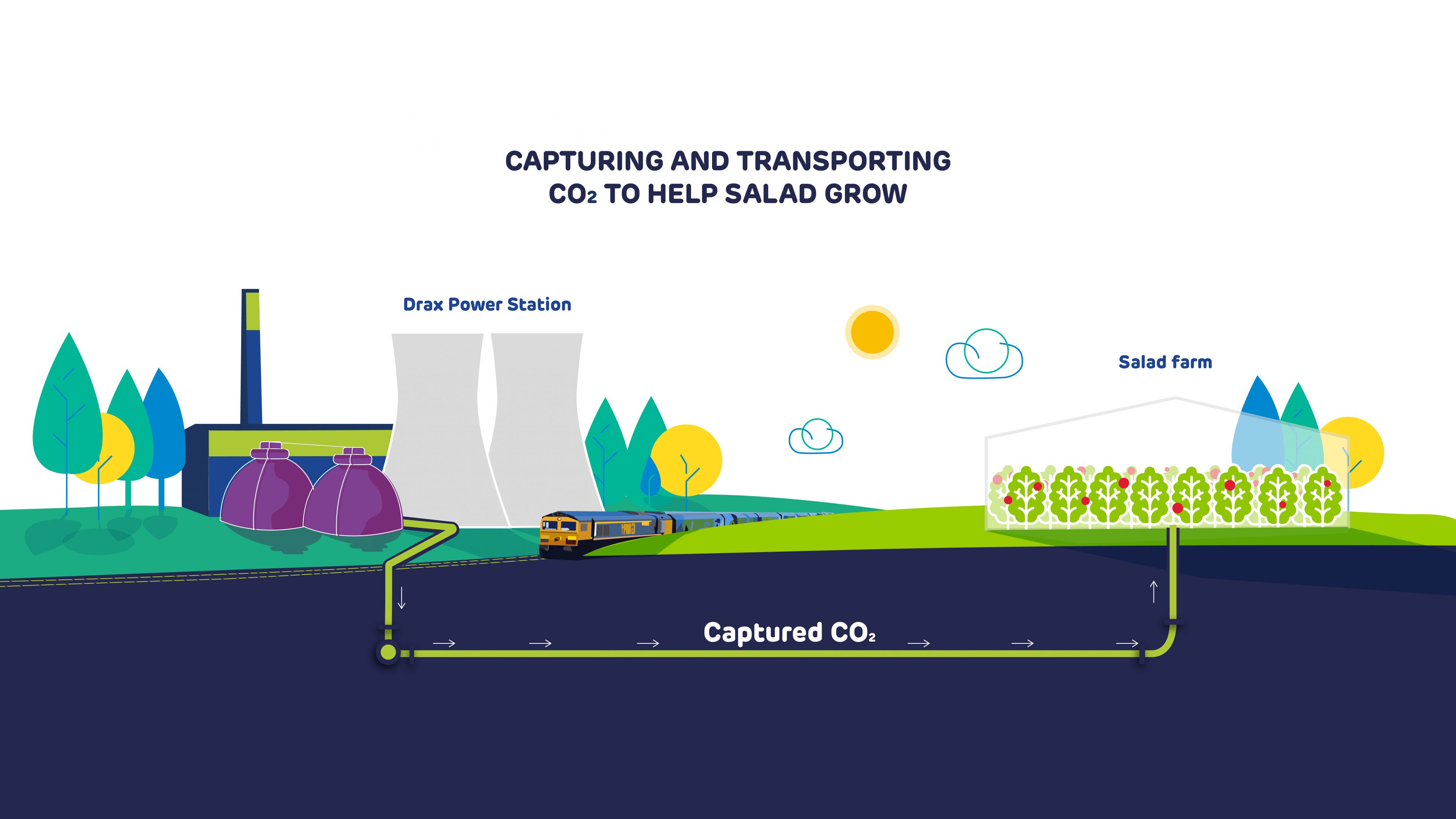

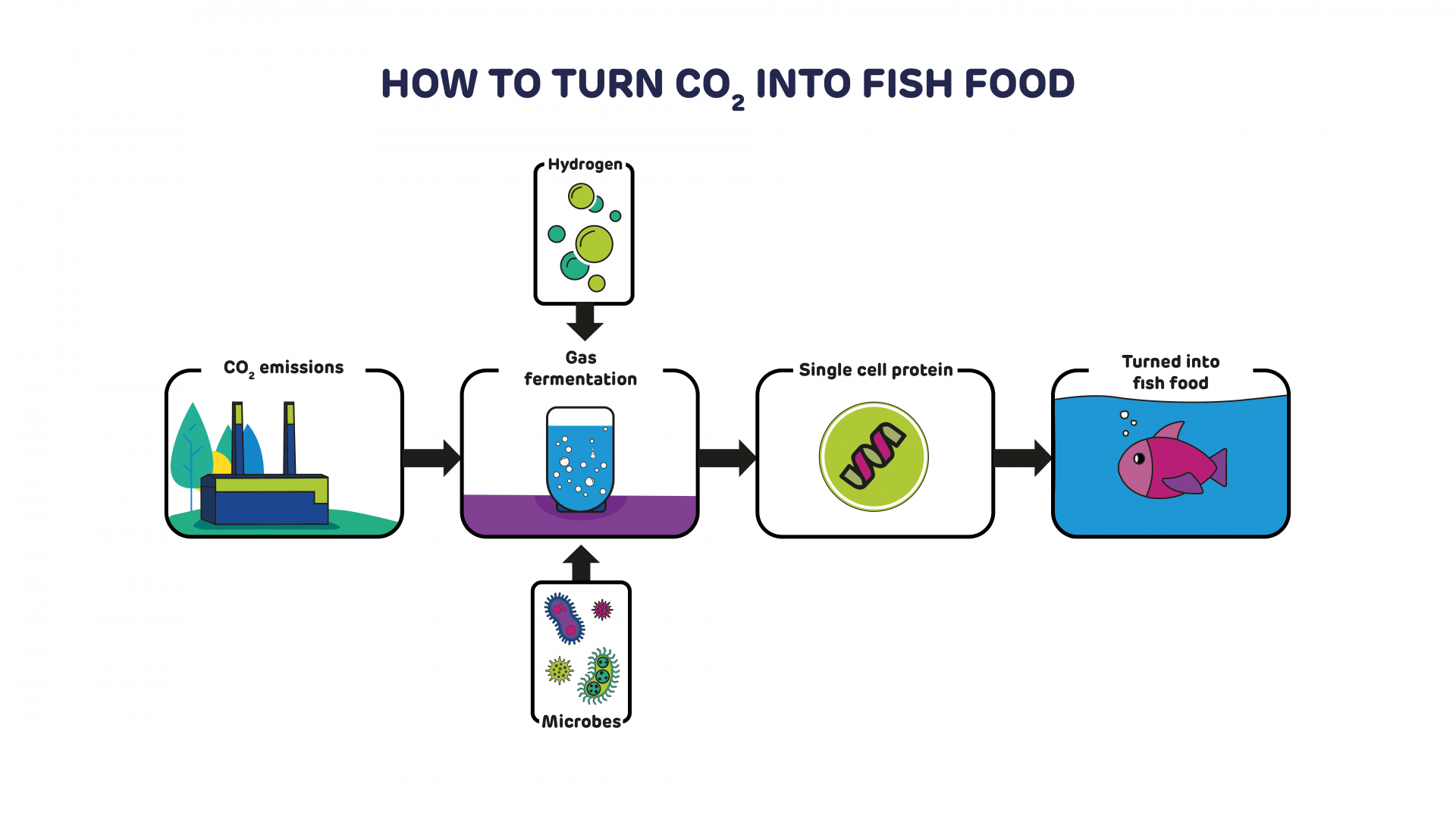

- Can we tackle two global challenges with one solution: turning captured carbon into fish food?

- How algae, paper and cement could all have a role in a future of negative emissions

- How the UK can achieve net zero

- Transforming emissions from pollutants to products

Burning waste and growing algae

Burning waste and growing algae Fully integrating BECCS into biomass power

Fully integrating BECCS into biomass power