‘Billie’, ‘Reggie’ and ‘Scottie’: Robotics in action at energy supplier

Robotics technology is transforming the operations of one of the UK’s biggest business energy suppliers.

The project at [Northampton/Oxford-based] Opus Energy has seen the technology, known as Robotic Process Automation (RPA), introduced for a number of processes within the company’s operations.

One automation running over the Christmas period cleared 20,000 tasks in a matter of days, saving staff at the firm, part of Drax Group, the UK’s biggest renewable electricity supplier to businesses, hours of mundane checking and data entry. It was also carried out at a time when normally staff would not have been available.

Plans are now being developed to rollout the robotic automations further into the firm’s operations. The energy supplier says the aim is to free up staff time to focus on more rewarding and engaging tasks, as well providing service improvements.

So far, six processes at the business have had automation introduced covering credit work, registrations, billing, metering and back office processes, with plans for further automations to be carried out throughout this year.

And the high-tech arrivals have been welcomed into the business by being given nicknames by the teams they work in. ‘Billie’ is now classed as part of the Billing team and is joined by ‘Reggie’ for Customer Registrations and ‘Scottie’ for Change of Tenancy (COT) work.

Ian Blackburn, heading the Intelligent Automation programme at Opus Energy, said: “The feedback from our operational teams has been great. The extra thinking time that RPA is already creating for our people is also really appreciated.

“By using this technology, we can free up their time and allow people to put their skills and expertise to better use and prevent them getting bogged down in more repetitive admin work. We’ll then see the benefit in terms of efficiencies but also in levels of staff motivation.

“We believe our customers will also see the positives in further improvements to our billing and customer services so it’s something that will potentially benefit everyone.”

Jonathan Kini, CEO of Drax Retail, which includes Opus Energy and Haven Power, added: “Innovation is at the heart of everything we do and the energy world is evolving quickly. Data and the way we use it will help our customers change the way they use energy, saving them money in the process and helping make their businesses more sustainable.

“The latest generation of smart meters will produce far better data so the quicker we can process that the better. Our people will then be able to focus on spending more time helping customers rather than data inputting and admin.”

Last year, it was confirmed that Opus Energy and Haven Power together had provided more than 350,000 UK businesses with renewable electricity, a new record which made them collectively the largest suppliers of renewable power to businesses in the UK.

The company is also currently trialling innovative battery storage technology at a farm in Northamptonshire which, if successful, would enable sustainable businesses to store power generated from their own solar panels or wind turbines, and then sell it back to the grid at peak times, providing an additional revenue source.

ENDS

Notes to editors:

Drax Power Station announced last year that it was going to pilot the use of robots in its administrative processes for checking in rail deliveries.

Media contacts:

Ali Lewis

Drax Group Head of Media & PR

E: ali.lewis@drax.com

T: 07712670888

Mark Duffell

MCD Communications Ltd

E: mduffell@mcdcomms.co.uk

T: 07969 080272

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

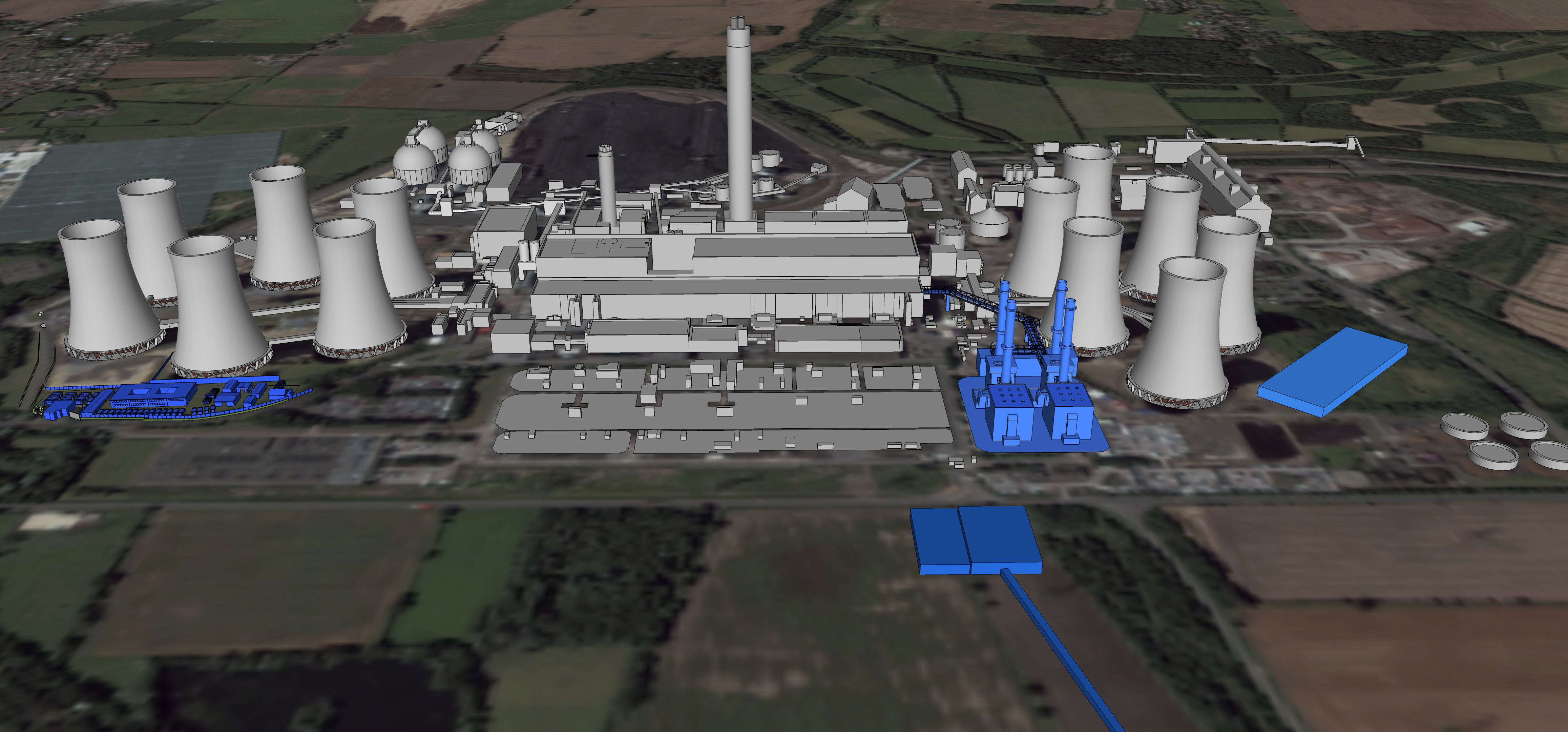

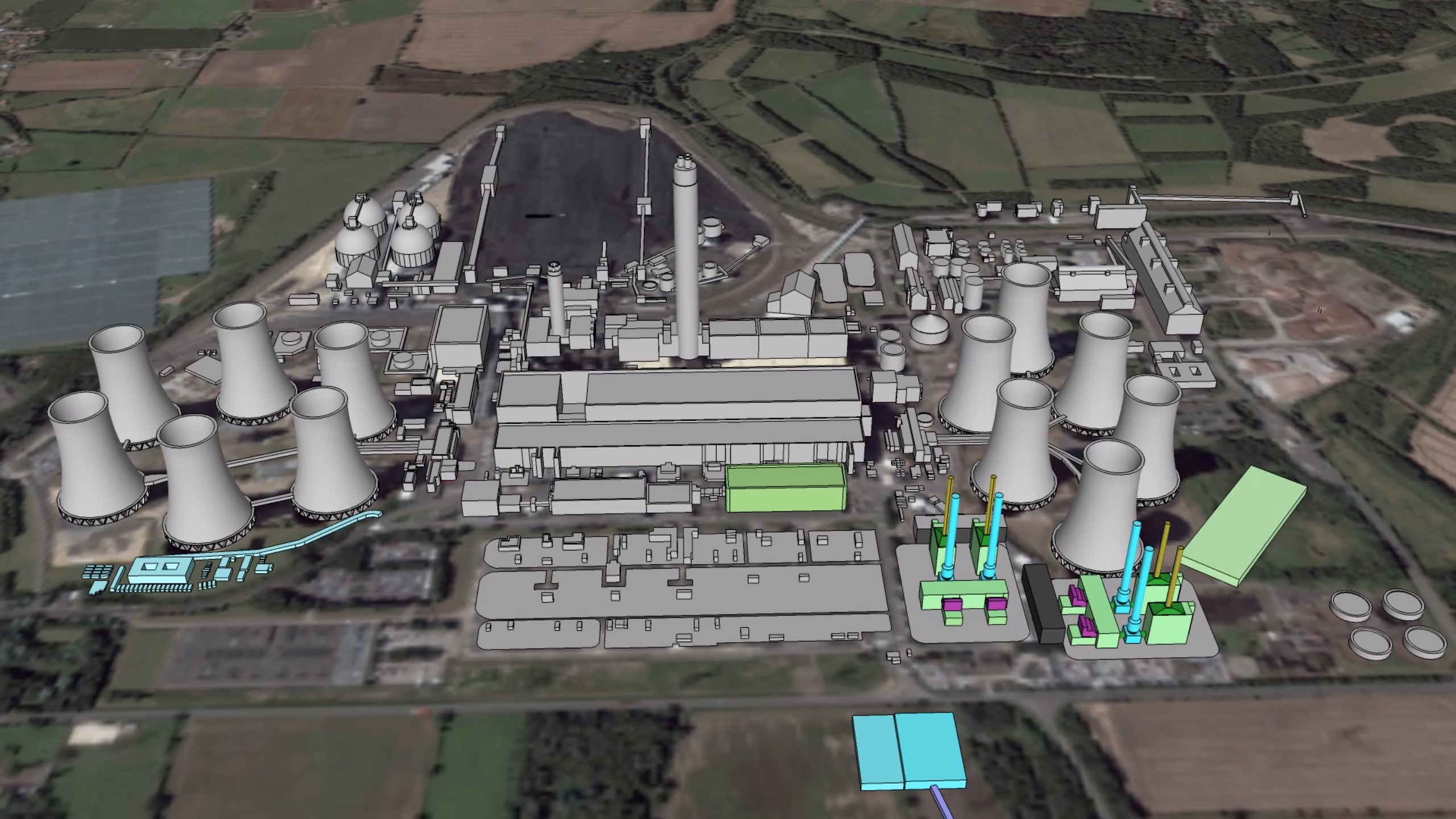

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies six percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

B2B supply:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com/uk