The iconic Cruachan facility in the Western Highlands can generate flexible power within seconds during times of peak demand, helping to keep the lights on for tens of thousands of households. It also provides crucial system support services to the electricity grid, enabling more renewables such as wind and solar to come onto the network.

Mr. Wheelhouse said:

“It was fascinating to learn more about how important this unique power station is in supporting the energy system and just how quickly it can respond to changes in demand – delivering the power needed in as little as 30 seconds.

“This kind of flexibility and resilience helps to support the growth of renewables, enabling further decarbonisation of the energy system as we strive for net zero carbon emissions in Scotland by 2045.

“The real value the technology adds every day to our energy system is the reason why we, and industry partners, continue to call on UK Ministers to take action to ensure that they provide the revenue certainty developers need to underpin further proposed investments in pumped storage hydro capacity in Scotland.”

(L-R) Drax CEO Generation Andy Koss, Scottish Energy Minister Paul Wheelhouse overlooking the turbine hall inside Cruachan Power Station.

Andy Koss, Drax’s CEO Generation, said:

“Cruachan has been providing stability to the power network since 1965 when the turbines were first installed inside the hollowed-out mountain. As we move to a system with more renewables, the services that Cruachan provides are becoming more essential.

“I’m incredibly proud of the work done by the team and the role they play in driving decarbonisation and economic growth as we continue to deliver the power relied on by thousands of homes and businesses.”

Cruachan is one of four pumped storage hydro stations in the UK and has a capacity of 440 MW – enough to power more than 90,000 homes during peak demand.

Built on the shores of Loch Awe in Argyll and Bute, it was the first reversible pumped storage hydro system on this scale to be built in the world.

The turbine hall is located 1 km within the hollowed-out mountain of Ben Cruachan and houses four generators, supplying a range of vital balancing and ancillary services to the grid, such as frequency control, spinning and operating reserves, helping to maintain secure power supplies.

Drax acquired Cruachan along with hydro facilities in Galloway and Lanark and a biomass-from-waste plant at Daldowie, near Glasgow, at the end of last year.

Scotland is targeting net zero carbon emissions by 2045 – five years ahead of the rest of the UK.

Top image caption: (L-R) Scottish Energy Minister Paul Wheelhouse, Drax CEO Generation Andy Koss, Drax Head of Hydro Ian Kinnaird outside the Cruchan Power Station.

ENDS

Media contacts:

Ali Lewis

Drax Group Head of Media & PR

E: [email protected]

T: 07712670888

Selina Williams

Drax Group Media Manager

E: [email protected]

T: 07912230393

Editor’s Notes

- Drax Group completed the acquisition of a portfolio of renewable, low-carbon and flexible power stations, in strategic locations across the country – from Scotland to the South East coast – on 31st December 2018.

- The plant has four primary modes of operation and can deliver a range of balancing and ancillary services.

- Cruachan acts responsively by generating electricity to meet peak-time demand. It can achieve full load in 30 seconds and can maintain its maximum power production for more than 16 hours if necessary.

- Cruachan’s Hollow Mountain visitor centre is also a popular tourist destination and was recently named by VisitScotland as one of its top visitor attractions.

- Guided tours are available through the Cruachan website <LINK> and school groups go free to encourage the next generation of engineers.

- This year, Drax recruited five apprentice engineers for its Scottish hydro sites, further boosting STEM education and local skills.

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

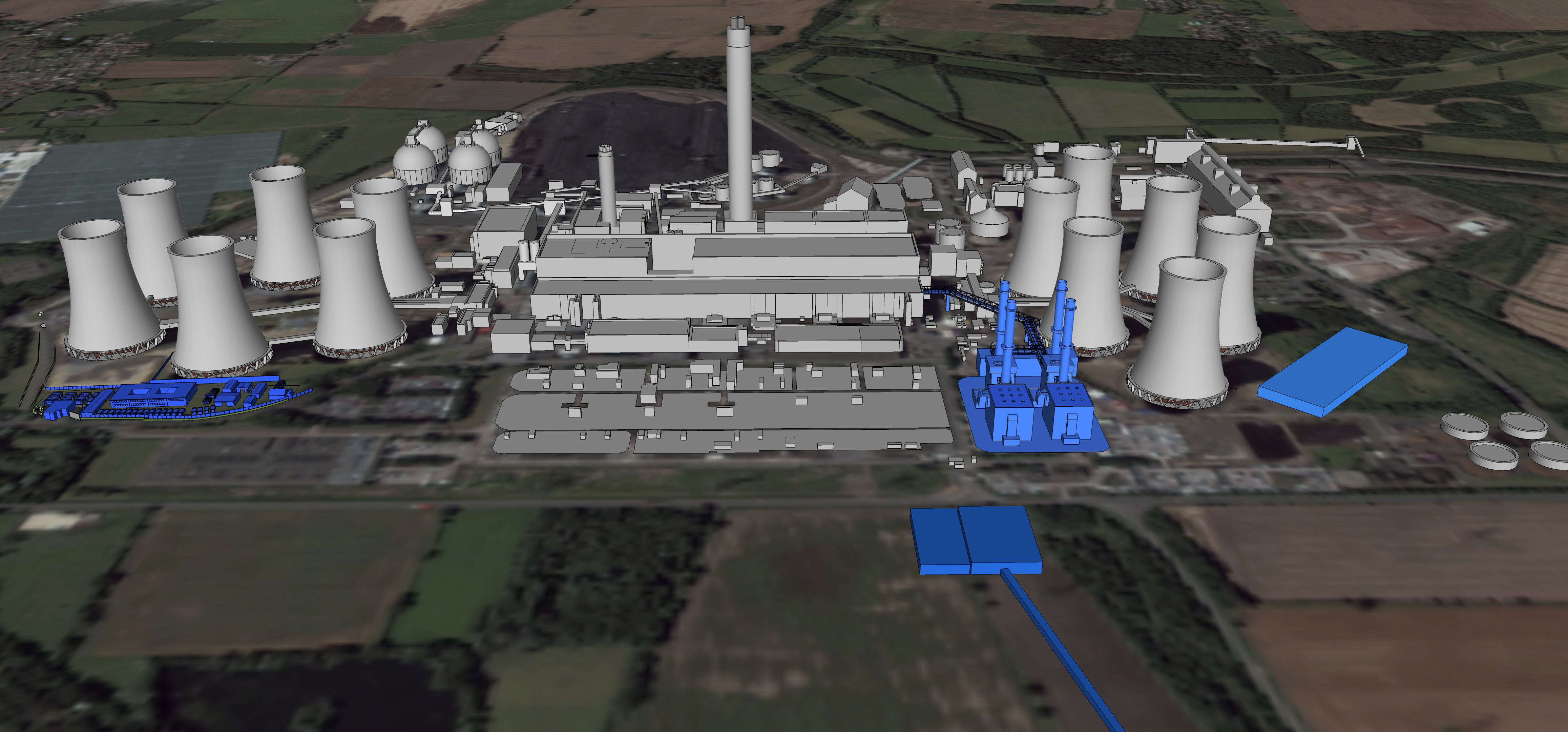

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage hydro facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

For more information visit www.drax.com/uk

Customers:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com/uk