-

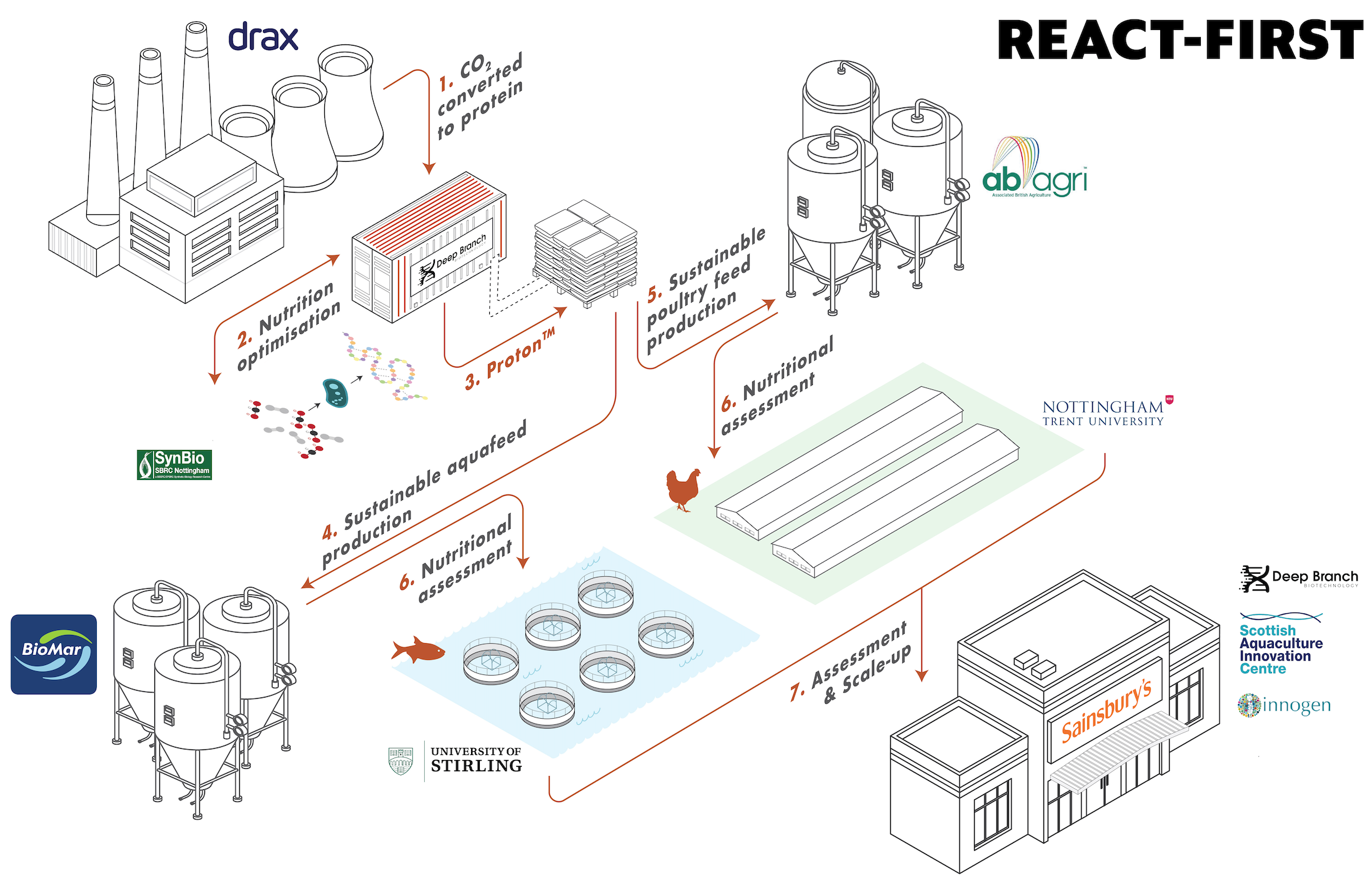

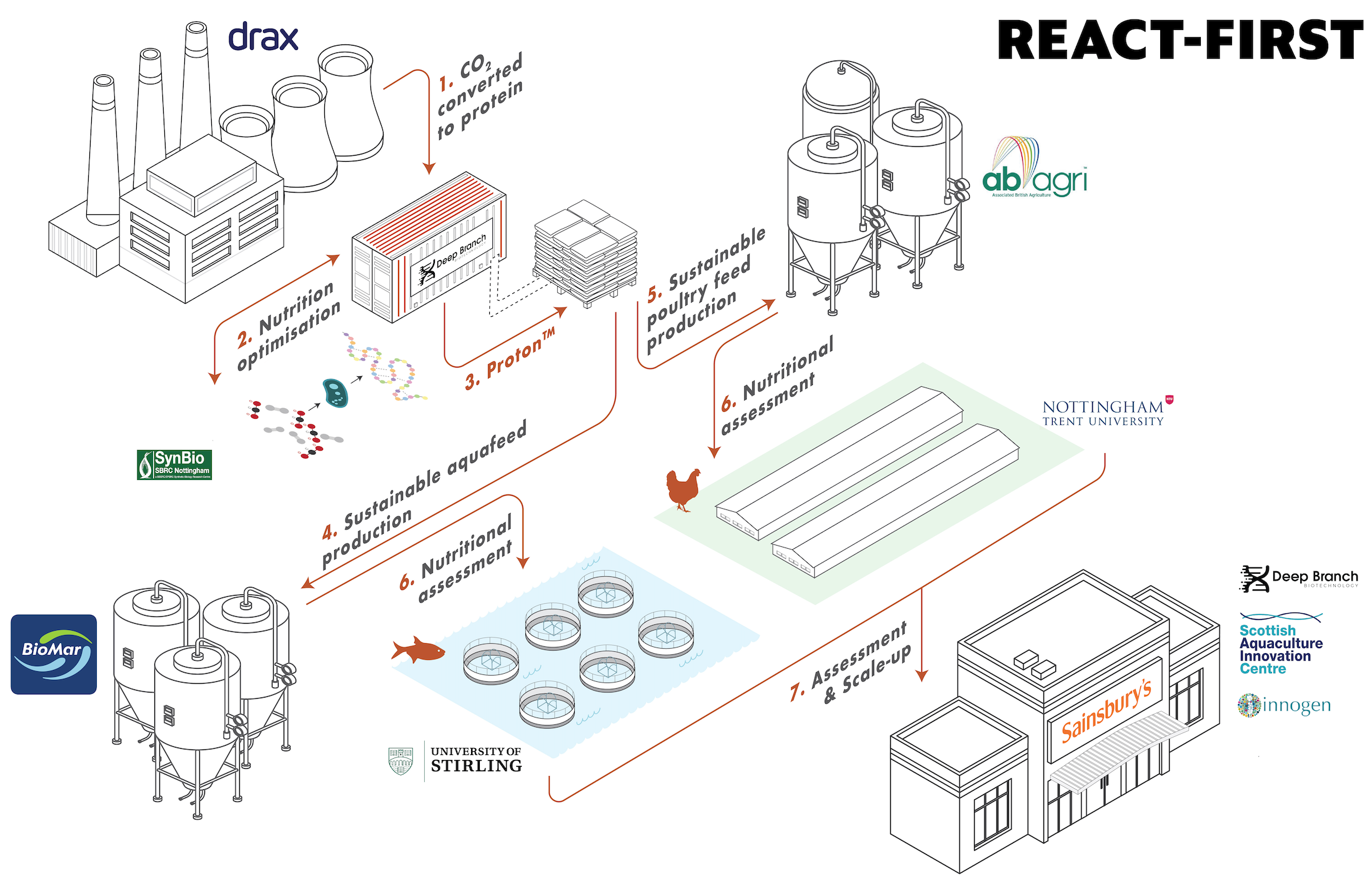

The project will obtain critical data about a new single-cell protein used in fish and poultry feed that is set to sustainably transform the UK’s aquaculture and poultry industries.

REACT-FIRST is the UK’s first-ever scalable route to the sustainable generation of protein capturing the carbon dioxide from bio-energy generation. It launches with financial support from the government in the form of £3M funding from Innovate UK and will contribute to meeting the UK’s Net Zero climate change commitment as well as to the circular economy.

REACT-FIRST is led by carbon recycling biotechnology company Deep Branch, which has pioneered a process that uses microbes to convert carbon dioxide from industrial emissions and turns them into high-value proteins.

The project launches with the first-of-its-kind, end-to-end value-chain-wide consortium of ten industry and academic partners, which all share a commitment to tackling the global climate crisis and the goal of achieving neutral / negative carbon emissions. The members of the REACT-FIRST consortium are:

- Deep Branch – experts in recycling industrial CO2 into cost-competitive protein for high-value, sustainable animal feed;

- Drax – the UK’s largest single site renewable electricity generator and pioneer of Bioenergy with Carbon Capture and Storage (BECCS);

- BioMar – one of the world’s largest aquafeed producers;

- AB Agri – a global agri-food business and leading producer of monogastric feed;

- Sainsbury’s – recognised as world’s best sustainable seafood retailer in 2017;

- Scottish Aquaculture Innovation Centre (SAIC) – a network of 100+ key stakeholders from the aquaculture industry;

- Synthetic Biology Research Centre, University of Nottingham (SBRC Nottingham) – the world-leading gas fermentation research group;

- The Institute of Aquaculture, University of Stirling – the UK’s leading aquaculture research centre;

- Nottingham Trent University, School of Animal Rural and Environmental Sciences – experts in assessing sustainable poultry production;

- Innogen, University of Edinburgh – experts in value chain integration and responsible innovation.

Commenting on the significance of the REACT-FIRST project, Peter Rowe, CEO of Deep Branch, explains:

“Currently, most animal feed protein sources are imported from overseas, making the UK dependent on complicated and fragile supply chains. REACT-FIRST has been created to focus solely on addressing this problem.

“Projects like REACT-FIRST are key to help the industry move towards achieving net-zero emissions. Its solution uses the technology developed by Deep Branch, but whilst this has huge transformative potential, commercialisation is not possible without cooperation with key stakeholders across the value chain. REACT-FIRST addresses this, with its consortium of industrial and academic organisations, and even though relationships within these verticals are well established, the project represents the first time that the resources and expertise of all parties have been unified towards a single goal.”

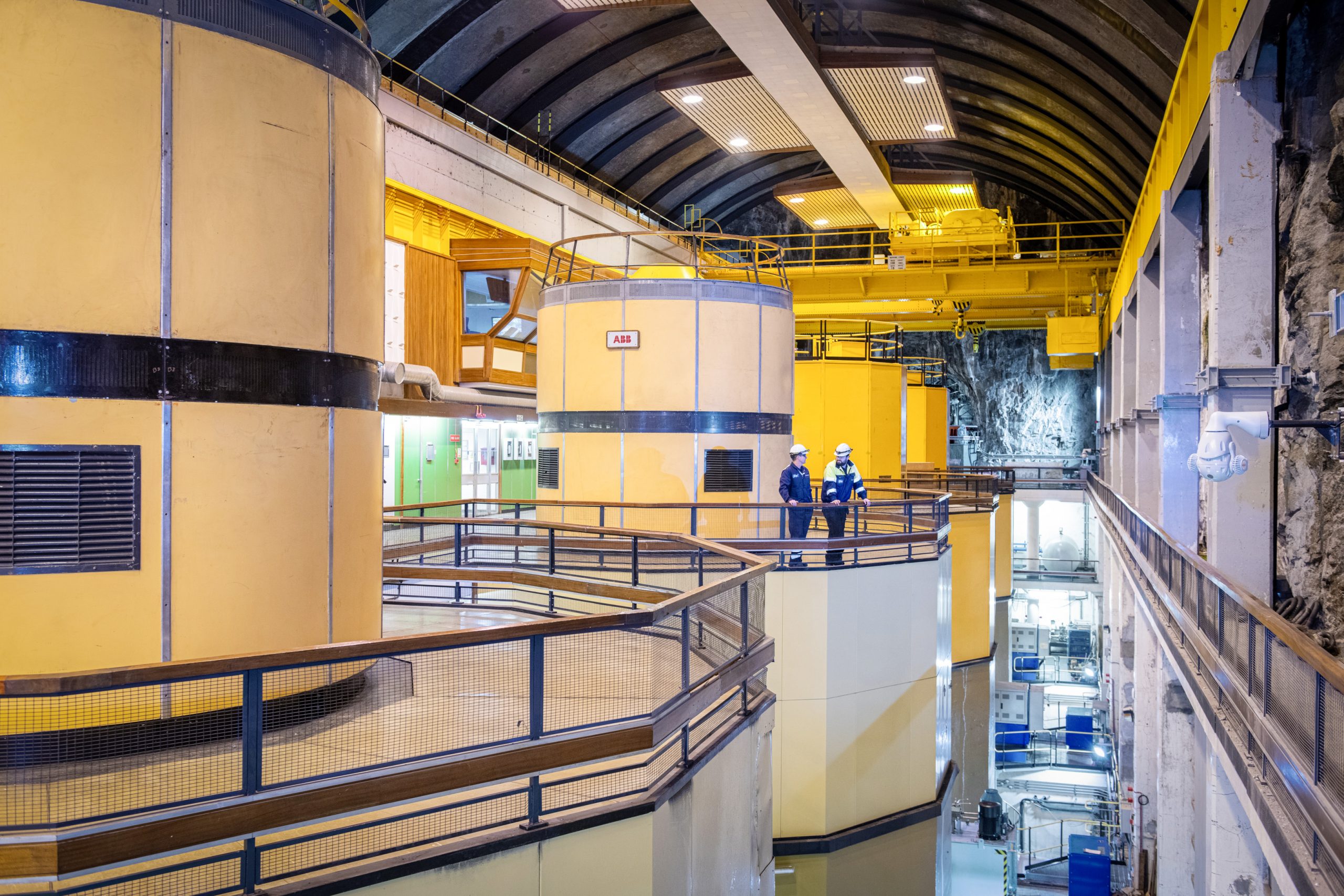

Deep Branch BioTechnology pilot plant within Drax’s CCUS incubation area

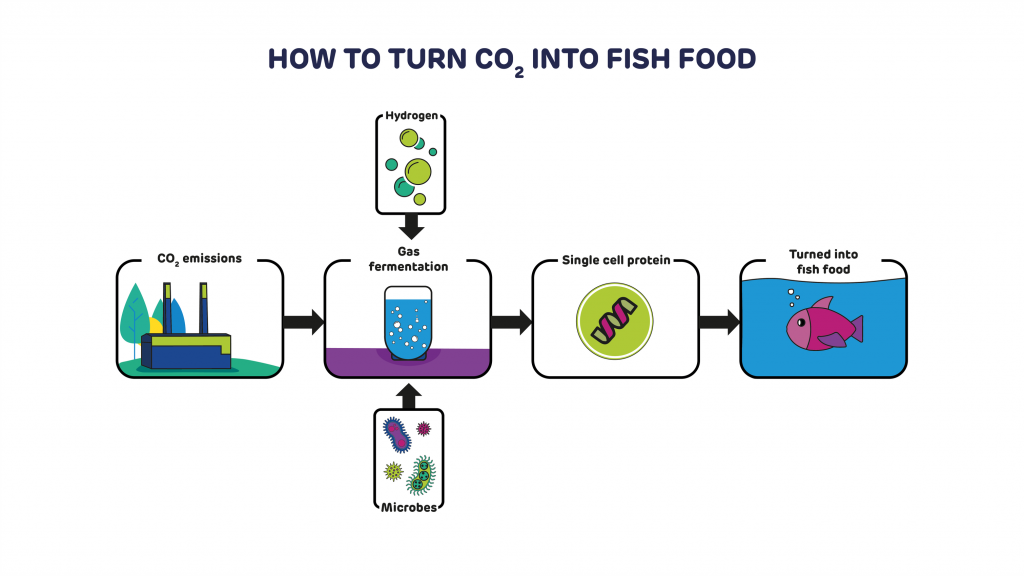

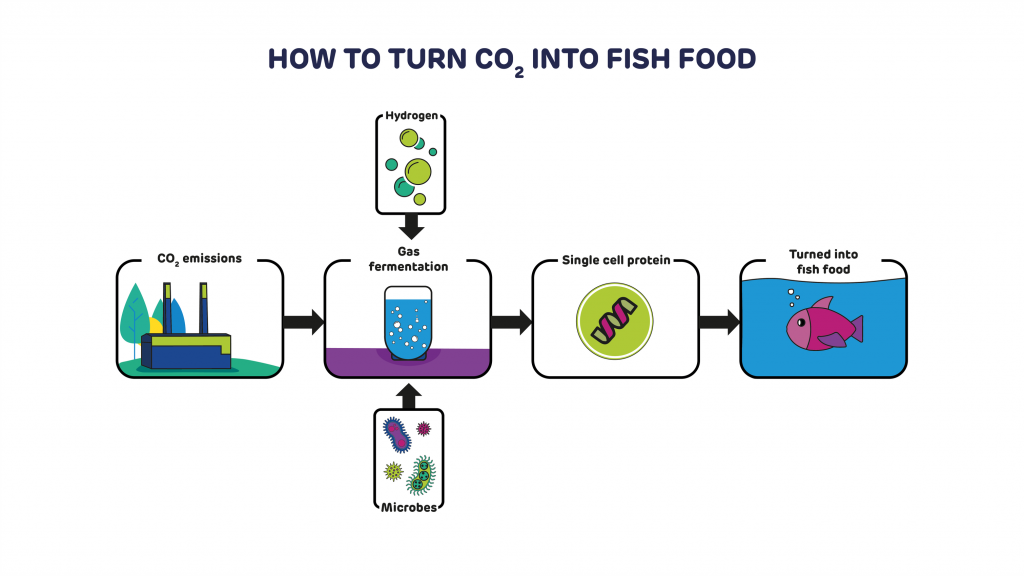

The work of REACT-FIRST centres around the use of microbes to convert CO2 directly from industrial emissions into high-value products, specifically a totally novel, new type of single-cell protein, or SCP, called ProtonTMproduced by Deep Branch. “This is used in fish and poultry feed and represents a new way of generating more sustainable animal feeds,” says Rowe.

“REACT-FIRST will obtain critical data about cost, digestibility, nutritional quality and carbon footprint of ProtonTM. Each of the project’s partners is playing an active role in the development of the process and generation of this critical data, harnessing their involvement and shared knowledge in the field of carbon emissions, the production supply chain, and ground-breaking biotechnology and technology, to create sustainable protein feed sources that will contribute to reducing the environmental impact of meat production systems.”

Speaking about the REACT-FIRST project, Science Minister Amanda Solloway said:

“To protect our environment and meet our world-leading target of Net Zero greenhouse gas emissions by 2050, we must harness the very best of UK innovation across all sectors, supporting the most creative and pioneering ideas.

“From robotics assisting our farmers in fruit picking, to technology that converts CO2-to clean animal feed, the incredible and cutting-edge projects we are backing today represent the future of farming. Working with the best of British science, we are accelerating the transition to net zero food production, boosting jobs and productivity and driving forward the UK’s economic recovery.”

Melanie Welham, Executive Director, BBSRC, part of UK Research and Innovation, adds:

“This project, and others like it will help increase UK agricultural productivity and global competitiveness. At UKRI our aim is to turnthe food production sector into a beacon of innovation. Brilliant ideas like this one go a long way to making food production more sustainable, efficient and less carbon intensive but they need support to get them from the drawing board to the farm.

“UKRI’s funding programme for this sector is ongoing. In our current funding round we’ve awarded funding to 9 innovative companies. In the future we encourage businesses to come forward with fresh ideas to help UK agriculture.”

REACT-FIRST partners:

Jason Shipstone, EVP Innovation

Drax Group last year announced its world-leading ambition to be carbon negative by 2030 by using Bioenergy with Carbon Capture and Storage (BECCS), and has been working with Deep Branch to explore the feasibility of using its carbon dioxide emissions to make proteins for sustainable animal feed products.

Through the REACT-FIRST project, Drax is providing further support through its expertise in site integration and CO2 lifecycle analysis, as Drax Group’s Chief Innovation Officer, Jason Shipstone, explains:

“By working with other businesses through the REACT-FIRST consortium, together we can help more difficult to de-carbonise sectors, like agriculture, to make positive changes to address the climate crisis.”

Global innovators in high performance aquaculture feed BioMar is involved in production of trial feeds and testing of the high potential raw material ProtonTM, focusing on sustainability, performance, digestibility and other parameters essential for fish health and growth.

Paddy Campbell, VP Salmon at BioMar Group, explains:

“Aquaculture is expected to double production by 2050 however to achieve this we need feeds with minimal environmental impact. The REACT-FIRST project is the first step towards the commercial development of a new potentially game-changing protein source, ProtonTM; using new technology to capture waste CO2 and creating high-value sustainable protein suitable for the aquaculture industry.

“At BioMar we are constantly seeking innovative raw materials that don’t compete with human food production and nutrients from by-products that minimise waste. We are excited to be part of this project to see how ProtonTM will perform in aquaculture feed,” stated Paddy Campbell VP Salmon, BioMar Group.

AB Agri’s role in REACT-FIRST is to complement the work of its consortium’s technology and science partners with its insights into animal feed markets, customer needs and end consumer demands. The agri-food company uses its expertise and experience to ensure end products are viable, and plays an integral role in driving a more responsible supply of protein around the world.

Valerie Schuster, Strategy Director at AB Agri, comments:

“The world around us is changing. In the past, there has been a growing gap between the animal feed industry and end consumers, who nowadays want to know more about the meat and fish they are eating, where they come from and whether the animals they consume have been raised responsibly. In turn, the industry is obliged to share more information about the feed animals consume, where it comes from, and how we do more with less to meet the needs of a growing population, while preserving the planet.

“REACT-FIRST provides a way of doing exactly this: by growing single-cell protein using CO2 emissions from industry, it creates a new, scalable and circular protein, which is the opportunity to help feed manufacturers and farmers and improve animal nutrition and wellbeing via a high-quality ingredient that is consistent and can easily be traced back to its origins.”

Scientists from the University of Stirling’s Institute of Aquaculture are tasked with investigating the feasibility of microbial single-cell protein (SCP) as a substitute for marine and terrestrial meal in salmon aquafeeds. The Institute’s Dr Mónica Betancor is leading the study, and explains: “The project aims to evaluate and validate a SCP produced from industrial emissions of CO2, with an amino acid profile tailored to meet the end-user requirements of the aquafeed industry, and also support and improve the sustainability and development of UK aquaculture by contributing to UK food security.

“Aquaculture is the fastest growing food sector, with the UK salmon industry expected to increase significantly. Such growth can only be achieved in a sustainable manner by replacing the traditionally used marine ingredients in aquafeeds – fish meal and fish oil – for more sustainable options. The main alternative to fish meal in aquafeeds is vegetable meal, however, this has its constraints, and single-cell protein is an excellent alternative as it is nutritionally optimised to meet the demands of aquaculture. Our work in the REACT-FIRST project will determine its feasibility as a substitute for other protein sources in the feeds for farmed salmon.”

Polly Douglas, aquaculture innovation manager at SAIC, adds:

“REACT-FIRST is a highly innovative way of turning the CO2 produced by another process into a key component of our food chain, providing a sustainable source of feed for fish. It could make a significant contribution to food security in the UK, while reducing the supply chain’s carbon footprint – both of which have seldom been of more relevance.”

The Synthetic Biology Research Centre (SBRC) at the University of Nottingham is one of the largest research centres of its kind in the world, and is focused on engineering bacteria to make industrially useful products from single carbon feedstocks – in particular greenhouse gases, CO2 and methane – with the overall goal to reduce reliance on petrochemicals by creating technologies that convert single carbon feedstocks into the chemicals, fuels and products society needs, including animal feed.

Of its role in REACT-FIRST, SBRC Director, Professor Nigel Minton, says:

“The SBRC has created a concentration of knowledge and expertise in aerobic gas fermentation for the UK. REACT-FIRST is a fantastic opportunity for the SBRC to work with like-minded organisations that share the passion to create sustainable routes to animal feed production systems. The project has the potential to make a real difference. REACT-FIRST’s joint industry: academia relationship is a conduit for the translation and adoption of UKRI-funded research. It is an important output of the SBRC’s research which will lead to significant outcomes from the SBRC’s research base, and we are delighted to provide SBRC’s unique facilities and expertise to support towards developing sustainable animal feed and in improving their nutritional characteristics.”

Experts from Nottingham Trent University’s Poultry Research Unit are tasked with investigating and benchmarking the nutritional quality of Proton™ as a poultry feed ingredient, advising on the processes to optimally prepare it for inclusion in the poultry feed, and conducting poultry nutrition trials. Once the nutritional evaluation is complete, NTU will work with the feed companies within the REACT-FIRST consortium to produce KPIs for improved protein ingredients profile based on commercial feed matrix data, which will be used to develop a report for the European Food Safety Authority to register the new feed materials.

Dr Emily Burton, Associate Professor in Sustainable Food Production at NTU, says:

“The poultry sector has much to be proud of in terms of low carbon meat production, but REACT-FIRST could catapult the sector into a completely new league. As well as providing access to a sustainable protein source, the project will help create stability for the animal production sector because feed represents about half of the total production costs for meat poultry.”

Along with providing the REACT-FIRST project with market-focused guidance throughout the lifecycle of the project, Sainsbury’s is assisting with stakeholder mapping and engagement in order to ensure maximum potential market acceptance, penetration and end-to-end value.

Sainsbury’s recently pledged to become Net Zero across its own operations by 2040, and REACT-FIRST’s focus aligns with these wider values, as Judith Batchelar, Director of Sainsbury’s Brand explains:

“Our customers care about where our products come from and they put their trust in us to do the right thing on their behalf. We’re proud to work closely with farmers, growers and suppliers in the UK and around the world to build resilient, sustainable and fairly-traded supply chains that will help more people live better today, tomorrow and in the future.

“Being part of the REACT-FIRST consortium is an outstanding opportunity to produce feeds for our farmed fish and chicken, with 65-75 percent smaller carbon footprints than existing feeds, no requirements for arable land, minimal water usage, and so we build more resilience into our supply chains for animal feed. REACT-FIRST should help the aquaculture and poultry feed industries move towards self-sufficiency from a dietary protein perspective, and reduce the instability of animal feed prices experienced by farmers.”

As well as assessing the economic, societal and environmental benefits of ProtonTM, a team at Innogen Institute at The University of Edinburgh is supporting REACT-FIRST to innovate responsibly and engage with relevant stakeholders to ensure wider acceptance of the technology. The University’s REACT-FIRST work is being led by Alan Raybold and Joyce Tait who are both involved in research and teaching programmes in the University of Edinburgh’s Global Academy of Agriculture and Food Security, an interdisciplinary hub committed to transforming global agri-food systems to achieve food and environmental security.

Alan Raybould, Chair of Innovation in the Life Sciences at the University, explains:

“REACT-FIRST is an exciting opportunity for Innogen to work with organisations throughout the animal-feed value chain to maximise the benefits of ProtonTM and increase the sustainability of animal-protein production systems.”

Joyce Tait, Founding Director of Innogen and Technical Author of the British Standards Institution (BSI) standard for Responsible Innovation (PAS440), adds:

“Innogen’s experience in supporting responsible innovation from a business point of view means we are ideally placed to enable REACT-FIRST to deliver and demonstrate a responsible innovation approach for ProtonTM production and commercialisation, including consumer acceptance.”

Geoff Simm, Director of the Global Academy of Agriculture and Food Security, adds:

“Sustainable protein feed sources will contribute to reducing the environmental impact of meat production systems. Projects like REACT-FIRST are key to help the industry move towards achieving net-zero emissions”.

For more information about REACT-FIRST: www.react-first.com and follow @reactfirstuk on Twitter.

View the Innovate UK press release via BEIS here.

ENDS

Captions for images supplied in support of this press release:

- (Infographic): Led by Deep Branch and utilising the unique resources available to each of the project partners, REACT-FIRST provides both technological and commercial innovation for aquaculture and poultry production. [Click to view/download]

Issued for and on behalf of REACT-FIRST and Deep Branch by V Formation Limited.

All media enquiries or for more information, contact:

Diane Wood: email: diane@vformation.biz or call: +44 (0) 115 787 0206 / +44 (0) 7887 794507.

About REACT-FIRST:

REACT-FIRST is led by Deep Branch, a carbon recycling biotechnology company. This project will obtain critical data about cost, digestibility, nutritional quality and carbon footprint of Proton™, a novel single-cell protein (SCP) produced by Deep Branch from CO2 directly from industrial emissions.

REACT-FIRST encompasses all key stakeholders in the Proton™ production value chain. Using feed industry-defined data and advanced robotics, this project aims to further improve the strong nutritional profile of Proton™ and sustainably disrupt the UK’s aquaculture and poultry industries.

REACT-FIRST represents an end-to-end value-chain-wide consortium of industry and academic partners, with the collective aim to transform the UK’s food production system. The project will validate the techno-economics of the Deep Branch innovative CO2-to-protein process, establishing Deep Branch as a precision technology company at the base of a low carbon food value chain. The group is united in recognising that animal agriculture must change both to ensure food security and for the UK to reach its net-zero CO2 target by 2050. By lowering the carbon footprint of animal feed, Proton™ can help to achieve this goal.

Currently, animal feed protein sources are imported from overseas, making the UK dependent on complicated and fragile supply chains. To address this problem, REACT-FIRST’s solution uses the technology developed by Deep Branch. Although this technology has huge transformative potential, commercialisation is not possible without cooperation with key stakeholders across the value chain – REACT-FIRST has been created to address this; it consists of groups of industrial and academic organisations, and even though relationships within these verticals are well established, this project represents the first time that the resources and expertise of all parties have been unified towards a single goal.

www.react-first.com

Members of the REACT-FIRST consortium are:

Industry:

- Deep Branch – experts in recycling industrial CO2 into cost-competitive protein for high-value, sustainable animal feed: deepbranchbio.com

- Drax – the UK’s largest single site renewable electricity generator and pioneer of Bioenergy with Carbon Capture and Storage (BECCS): drax.com

- BioMar – one of the world’s largest aquafeed producers: biomar.com

- AB Agri – a global agri-food business and leading producer of monogastric feed: abagri.com

- Sainsbury’s – recognised as the world’s best sustainable seafood retailer in 2017 sainsburys.co.uk

- SAIC (Scottish Aquaculture Innovation Centre) – a network of 100+ key stakeholders from the aquaculture industry: scottishaquaculture.com

Academic:

- SBRC Nottingham – Synthetic Biology Research Centre, University of Nottingham – the world-leading gas fermentation research group: sbrc-nottingham.ac.uk

- The Institute of Aquaculture, University of Stirling – the UK’s leading aquaculture research centre: stir.ac.uk

- Nottingham Trent University’s School of Animal, Rural and Environmental Sciences – experts in assessing sustainable poultry production. More on NTU’s poultry research here.

- Innogen, University of Edinburgh – experts in value chain integration and responsible innovation: innogen.ac.uk

More about REACT-FIRST partners:

Deep Branch:

Deep Branch is a carbon recycling biotechnology company using microbes to convert carbon dioxide from industrial emissions into high-value products. A fast-growing and agile startup with commercial activities both in the UK and the Netherlands enabling local year-round protein production to ensure food security.

Deep Branch address the animal feed market’s need for sustainable and cost-effective protein ingredients with ProtonTM, a radically more sustainable way to bring precision nutrition to animal diets. Deep Branch’s CO2 -to-X platform offers the first scalable route to a truly sustainable protein generation process from a waste product – CO2 directly from industrial emissions.

For more information, visit: www.deepbranchbio.com

Drax is working with biotech start-up Deep Branch Biotechnology to explore the feasibility of using the power station’s carbon dioxide emissions to make proteins for sustainable animal feed products. View the press release here.

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using Bioenergy with Carbon Capture and Storage (BECCS) technology. Its 2,900-strong employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

- Power generation: Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs. Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal, it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area. Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

- Customers: Through its two B2B energy supply brands, Haven Power and Opus Energy, Drax supplies energy to 250,000 businesses across England, Scotland and Wales.

- Pellet production: Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

BioMar are innovators in high performance aquaculture feed dedicated to doing our part in creating a healthy and sustainable global aquaculture industry. It operates 16 feed factories across the globe in Norway, Chile, Denmark, Scotland, Spain, France, Greece, Turkey, China, Costa Rica, Ecuador and Australia. Worldwide, we supply feed to around 80 countries and for more than 45 different species. BioMar is wholly owned by the Danish industrial group Schouw & Co, which is listed on the NASDAQ, Copenhagen.

AB Agri is made up of 3000+ talented people all contributing to the entire food supply chain, working with customers around the globe to produce sustainable food sources for a growing population. For over 30 years we have been committed to changing agriculture for the better so that the food we eat is produced safely and in a responsible way. Our products and services reach 5 million farmers worldwide, we enrich the diets of 1 in 5 chickens globally and we operate in over 65 countries. AB Agri is part of Associated British Foods (ABF), a diversified international food, ingredients and retail group with sales of £15.8bn, 138,000 employees and operations in 52 countries across Europe, southern Africa, the Americas, Asia and Australia.

Helping our customers get the most out of life has been at the heart of what we do since 1869 and we achieve this by offering our customers easy, affordable access to the things they need, like healthy food, quality clothes, stylish homewares, the latest technology and more ways to manage their money. We do all of this sustainably, so we can help our customers live well for less today and tomorrow. We are a leading multi brand, multi-channel retailer, with a growing online and digital business, fast, convenient delivery capability and a structurally advantaged store estate of over 1,400 Sainsbury’s supermarkets and convenience stores and almost 900 Argos stores in stand-alone and supermarket locations. The Habitat brand is available in 16 locations and online. We employ 178,000 colleagues who are integral to our success, now and in the future.

SAIC’s mission is to transform Scottish aquaculture by unlocking sustainable growth through innovation excellence. We invest in collaborative research projects in the areas of fish health and welfare, nutrition, shellfish production, capacity and sustainable industry growth. We also help grow the industry’s talent pool by supporting MSc and PhD places, internships and training programmes.

The Synthetic Biology Research Centre (SBRC), University of Nottingham: www.sbrc-nottingham.ac.uk

SBRC at the University of Nottingham is one of six centres established by the Biotechnology and Biological Sciences Research Council (BBSRC) and the Engineering and Physical Sciences Research Council (EPSRC). The Nottingham SBRC is focused on engineering bacteria to make industrially useful products from single carbon (C1) feedstocks, and in particular the greenhouse gases, carbon dioxide (CO2) and methane (CH4). It is one of the largest research centres of its kind in the world and has an overall goal to reduce reliance on petrochemicals by creating technologies which convert C1 feedstocks into the chemicals, fuels and products society needs, including animal feed. The SBRC has created a concentration of knowledge and expertise in aerobic gas fermentation for the UK. This UK project is a fantastic opportunity for the SBRC to work with a new UK company which shares the passion to create sustainable routes to animal feed production systems. This collaboration and up-scaling of aerobic fermentation is an important step forwards for the SBRC’s ambition to turn greenhouse gases from pollutants into sustainable products, breaking our reliance on petrochemicals, ameliorating climate change and reducing the need to convert more land (such as rain-forest) into farmland to grow animal feed.

The University of Nottingham is a research-intensive university with a proud heritage, consistently ranked among the world’s top 100. Studying at the University of Nottingham is a life-changing experience and we pride ourselves on unlocking the potential of our 44,000 students – Nottingham was named both Sports and International University of the Year in the 2019 Times and Sunday Times Good University Guide, was awarded gold in the TEF 2017 and features in the top 20 of all three major UK rankings. We have a pioneering spirit, expressed in the vision of our founder Sir Jesse Boot, which has seen us lead the way in establishing campuses in China and Malaysia – part of a globally connected network of education, research and industrial engagement. We are ranked eighth for research power in the UK according to REF 2014. We have six beacons of research excellence helping to transform lives and change the world; we are also a major employer and industry partner – locally and globally.

The University of Stirling is ranked fifth in Scotland and 40th in the UK for research intensity in the 2014 Research Excellence Framework. Stirling is committed to providing education with a purpose and carrying out research which has a positive impact on communities across the globe – addressing real issues, providing solutions and helping to shape society. Interdisciplinary in its approach, Stirling’s research informs its teaching curriculum and facilitates opportunities for knowledge exchange and collaboration between staff, students, industry partners and the wider community. The University’s scenic central Scotland campus – complete with a loch, castle and golf course – is home to more than 14,000 students and 1500 staff representing around 120 nationalities. This includes an ever-expanding base for postgraduate study. The University received a Queen’s Anniversary Prize in the latest round of awards, in recognition of the quality and innovation exhibited by its Institute of Aquaculture. The University is the UK Sports University of the Year 2020, as conferred by The Times / Sunday Times Good University Guide.

Nottingham Trent University (NTU): www.ntu.ac.uk

NTU was named University of the Year 2019 in the Guardian University Awards. The award was based on performance and improvement in the Guardian University Guide, retention of students from low-participation areas and attainment of BME students. NTU was also the Times Higher Education University of the Year 2017, and The Times and Sunday Times Modern University of the Year 2018. These awards recognise NTU for its high levels of student satisfaction, its quality of teaching, its engagement with employers, and its overall student experience. The university has been rated Gold in the Government’s Teaching Excellence Framework – the highest ranking available. NTU is one of the largest UK universities. With nearly 32,000 students and more than 4,000 staff located across four campuses, the University contributes £900m to the UK economy every year. With an international student population of more than 3,000 from around 100 countries, the University prides itself on its global outlook. The university is passionate about creating opportunities and its extensive outreach programme is designed to enable NTU to be a vehicle for social mobility. NTU is among the UK’s top five recruiters of students from disadvantaged backgrounds and was awarded University of the Year in the UK Social Mobility Awards 2019. A total of 82% of its graduates go on to graduate entry employment or graduate entry education or training within six months of leaving. Student satisfaction is high: NTU achieved an 87% satisfaction score in the 2019 National Student Survey.

The Innogen Institute (Institute for Innovation Generation) is a partnership between the University of Edinburgh and The Open University that produces high-quality research and supports the delivery of responsible and sustainable innovation in science and technology. Researchers at Innogen are pioneering interdisciplinary and problem-led approaches that connect people, policy and practice to deliver innovative solutions for real-world problems. Since it was founded in 2002 as the ESRC Innogen Centre, Innogen has built a strong and unique body of work with national and international impact on the regulation and governance of innovation in science and technology.