Reducing carbon dioxide (CO2) emissions is one today’s greatest global challenges. But it‘s far from the only issue the world faces. The global population is expected to grow by a third to hit 10 billion by 2050 – an incredible growth that will place huge stress on securing a sustainable source of nutritious, healthy food for future generations.

One UK start-up, Deep Branch Biotechnology, is aiming to tackle both problems with a single solution that utilises captured CO2 emissions to create animal feed protein. In the past, Drax has explored using CO2 captured from its biomass units to help prevent a looming summer beer shortage. Now it’s partnering with Deep Branch to test if captured CO2 can solve some of agriculture’s most-pressing problems.

Broken food chain

The amount of land and resources dedicated to producing animal feed is increasingly unsustainable. A third of all the earth’s cropland is currently used to grow feed crops for livestock, which adds up to more than 90% of all global soy, and 60% of all cereals.

Soy seedlings

“The process of creating the protein we eat on our plates is extremely resource inefficient,” says Peter Rowe, Deep Branch CEO. “It takes about 6 kilograms (kg) of feed to produce one kg of pork. Soy is one of the world’s most widely produced crops but more than 90% of it goes into animal feed.”

It’s not just on land where feed crops are creating problems. Of fish caught around the world, an incredible 25% is processed into fishmeal for the aquaculture, or fish farming, industry. The demand for fishmeal is such that at present it outpaces demand for fish.

Even with an increasing number of people shifting to meat-free diets and more alternatives making headlines, meat production is still expected to double by 2050.

These industries need serious overhauls if they are to sustain into the coming decades. Deep Branch, helped via funding from Innovate UK, is looking to aquaculture as a test bed for sustainable protein production whilst also encouraging CO2 capture.

Turning carbon to carp

The secret behind Deep Branch’s approach to turning emissions into fish food is a strain of bacteria that feeds on CO2.

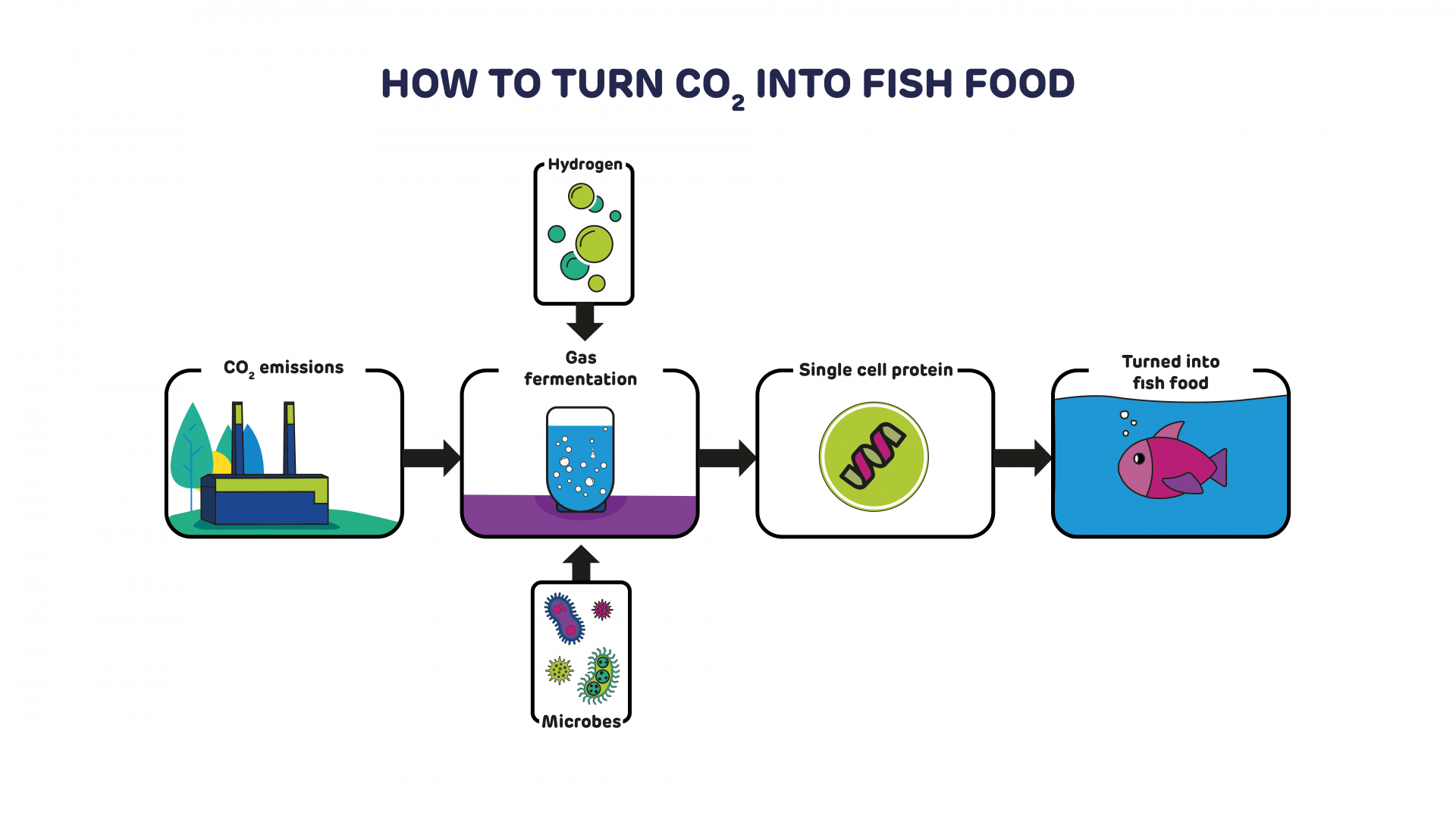

The partnership will see Deep Branch connect directly to a source of CO2, with the start-up taking up residence in Drax’s carbon capture usage and storage (CCUS) incubator space. Here, flue gas from one of Drax’s biomass power generation units will be fed into Deep Branch’s system, along with hydrogen, enabling a process known as gas fermentation to take place.

Download graphic: High Res (no logo) High Res (with logo)

“Normally when people think of fermentation, they think about something like wine, where sugar is converted into alcohol with a yeast acting as the biological catalyst,” says Rowe. “Our process, however, uses CO2 and hydrogen instead of sugar. Rather than yeast, our proprietary bacterium acts as the biological catalyst and converts these gases into protein.”

The resulting product is single cell protein, which comes out as a milk-like liquid when harvested. It’s then dried into powder and 70% of what remains are proteins that can be used as a fishmeal replacement.

One of the advantages of Deep Branch’s system is that rather than requiring energy to separate CO2, flue gas can be delivered directly to microbes, which can convert up to 70% of the captured CO2 into proteins. But for such a system to have a real impact it needs to be deployed at scale.

Scaling up

The process has been trialled in labs and proved highly efficient, with ten kg of CO2 producing seven kg of protein. What this new partnership with Drax offers is the opportunity to test Deep Branch’s process and technology at grid-scale. And while Deep Branch is focusing on aquaculture for now, the concept could potentially reach much further through the food chain.

Fish feed

“Because Drax’s biomass units are carbon neutral at the point of generation, the process creates an extremely low-carbon protein,” explains Rowe. “If you divorce the negative environmental impacts of industries like agriculture from its growth then you can provide more whilst impacting less.”

Deployed at global scale the idea of carbon-neutral protein would free up some of the arable land currently being used for soy and other feed crops. It means that as well as cutting the carbon intensity of traditional protein sources, more land would be available for other uses, while helping to halt climate change.

Learn more about carbon capture, usage and storage in our series:

- Planting, sinking, extracting – some of the ways to absorb carbon from the atmosphere

- From capture methods to storage and use across three continents, these companies are showing promising results for CCUS

- Why experts think bioenergy with carbon capture and storage will be an essential part of the energy system

- The science of safely and permanently putting carbon in the ground

- The numbers must add up to enable negative emissions in a zero carbon future, says Drax Group CEO Will Gardiner.

- The power industry is leading the charge in carbon capture and storage but where else could the technology make a difference to global emissions?

- From NASA to carbon capture, chemical reactions could have a big future in electricity

- A roadmap for the world’s first zero carbon industrial cluster: protecting and creating jobs, fighting climate change, competing on the world stage

- How algae, paper and cement could all have a role in a future of negative emissions

- How the UK can achieve net zero

- Transforming emissions from pollutants to products

- Drax CEO addresses Powering Past Coal Alliance event in Madrid, unveiling our ambition to play a major role in fighting the climate crisis by becoming the world’s first carbon negative company