Capture For Growth

The starting gun has fired and the challenge is underway. The government has officially set 2050 as the target year in which the UK will achieve carbon neutrality.

There’s no denying this economy-wide transformation will need a great deal of investment. Reaching net zero carbon emissions will require an evolutionary overhaul of not just Great Britain’s electricity system but the UK economy as a whole. And indeed, the way we live our lives and go about our business.

But that doesn’t mean it’s out of reach. Instead it will fall to technologies such as carbon capture usage and storage (CCUS), as well as bioenergy with carbon capture and storage (BECCS), to make it economical and possible.

The UK’s Committee on Climate Change (CCC) estimates the price of decarbonisation will cost as little as 1% of forecast GDP per annum in 2050.

However, the Business, Energy and Industrial Strategy (BEIS) Select Committee inquiry found that failure to deploy CCUS and BECCS technology could double the cost to 2%. There are a number of reasons for this, such as the cost to jobs, productivity and living standards of shutting down industrial emitters. CCUS’s ability to contribute to a hydrogen economy can help avoid this.

Moreover, the CCC claims even with industries striving to decarbonise rapidly, as much as 100 megatonnes of hard-to-abate carbon dioxide (CO2) is expected to remain in the UK economy by 2050.

This makes carbon negative techniques and technologies, such as BECCS – which uses woody biomass that has absorbed carbon in its lifetime as forests – alongside direct air capture (DAC), the boosting of ocean plant productivity, much greater tree planting and better sequestration of carbon in soil, essential if the UK is to attain true carbon neutrality.

The importance of BECCS and CCUS in the zero carbon future is clear. Now is the time for rapid development. Not in 2030, not in 2040, but today in 2019 and into the 2020s.

But doing this requires the government to move beyond its historic policies that have failed to support the technology in the past. Progress needs long-term frameworks that provide private sector investors with the certainty they need to kick-start the commercial-scale deployment of CCUS technologies.

For carbon capture to become an integrated part of the energy system it must deliver value well beyond the energy sector. Establishing markets for products developed from captured carbon will play a role here, but to set the wheels in motion, financial frameworks are needed that can allow BECCS and CCUS to thrive.

One device that can allow the market to develop CCUS is the creation of contracts for difference (CfDs) for carbon capture. These currently exist in the low-carbon generation space, between generators and the government-owned Low Carbon Contracts Company (LCCC). Through these contracts, power generators are paid the difference between their cost of generating low carbon electricity (known as a strike price) and the price of electricity in Great Britain’s wholesale power market. If the power price in the market is higher than the strike price generators pay the difference back to the LCCC, meaning consumers are protected from price spikes too.

It means that the generator is protected from market volatility or big drops in the wholesale price of power, offering the security to invest in new technology. More than this, CfDs last many years meaning they transcend political cycles and the cost per megawatt can be reduced with a longer contract. Creating a market for carbon capture or negative emissions generation could offer the same security to generators to invest in the technology.

A CfD for BECCS should not only incentivise the building of infrastructure to capture carbon, but we must also recognise the valuable role that negative emissions can play. By compensating BECCS producers for their negative emissions, it should provide a lower cost alternative to reducing all other CO2 emissions to zero, while still ensuring that the UK can get to net zero.

Beyond installing carbon capture at existing generation sites, one of the major financial barriers to the wider deployment of CCUS and BECCS is the cost and liability associated with transporting and storing captured carbon.

A Regulated Asset Base (RAB) funding model, would encourage investment by gradually recovering the costs of transport and storage via a regulated return. This approach is currently under consideration as a means of financing other major infrastructure projects.

A RAB allows businesses, including investment and pension funds, to invest in projects under the oversight of a government regulator. In exchange for their commitment, investors can collect a fee through regular consumer and non-domestic bills.

Ultimately, the current carbon trading system is based around charging polluters. But as we approach a post-coal UK and in order to achieve net zero, it’s necessary for this to evolve – from economically disincentivising emissions to incentivising carbon-negative power generation.

However, with the cost of carbon capture and negative emissions differing between types of industries and technologies, there’s a requirement to consider differentiated carbon prices to guide industry through long-term strategy. But the need for carbon capture development is too pressing for us as an industry to wait.

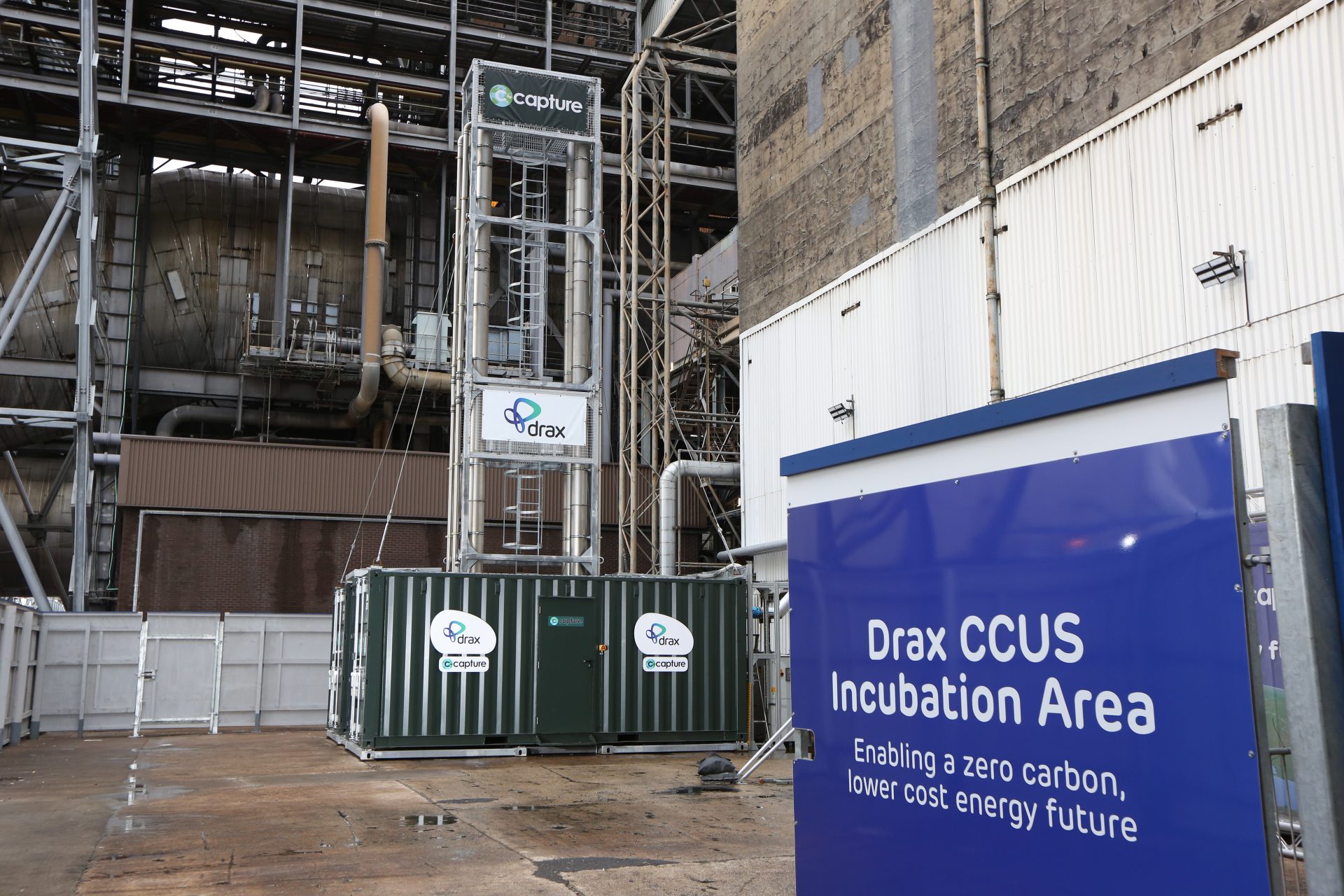

At Drax Power Station our BECCS pilot is just the beginning of our wider ambitions to become the first negative emissions power station. Our use of biomass already makes Drax Power Station the largest generator of renewable electricity in Great Britain. The responsibly-managed working forests our suppliers source from absorbed carbon from the atmosphere as they grew so adding carbon capture at scale to this supply chain can turn our operation from low carbon, to carbon-neutral and eventually carbon negative.

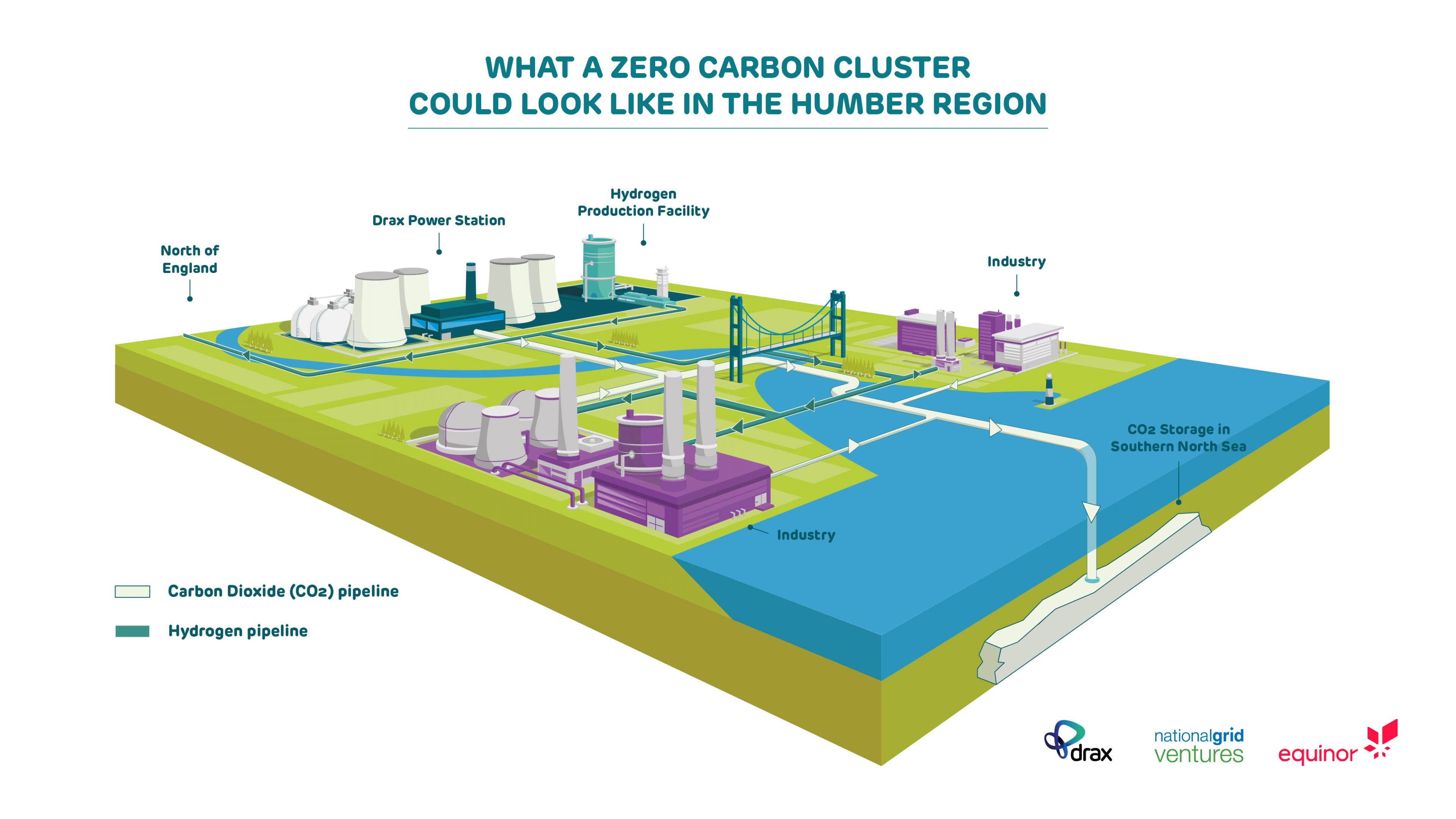

And we have bigger plans still to create a net zero carbon industrial cluster in the Humber region, in partnership with Equinor and National Grid. The cluster would deliver carbon capture at the scale needed to not just decarbonise the most carbon-intensive industrial region in the UK, but to put the country at the forefront of the decarbonisation of industry and manufacturing.

Government action is needed to make CCUS and BECCS economically sustainable at scale as an integrated part of our energy system. However, the onus is on us, the energy industry to lead development and act as trusted partners that can deliver the decarbonisation needed to reach net zero carbon by 2050.

Reducing carbon dioxide (CO2) emissions is one today’s greatest global challenges. But it‘s far from the only issue the world faces. The global population is expected to grow by a third to hit 10 billion by 2050 – an incredible growth that will place huge stress on securing a sustainable source of nutritious, healthy food for future generations.

One UK start-up, Deep Branch Biotechnology, is aiming to tackle both problems with a single solution that utilises captured CO2 emissions to create animal feed protein. In the past, Drax has explored using CO2 captured from its biomass units to help prevent a looming summer beer shortage. Now it’s partnering with Deep Branch to test if captured CO2 can solve some of agriculture’s most-pressing problems.

The amount of land and resources dedicated to producing animal feed is increasingly unsustainable. A third of all the earth’s cropland is currently used to grow feed crops for livestock, which adds up to more than 90% of all global soy, and 60% of all cereals.

Soy seedlings

“The process of creating the protein we eat on our plates is extremely resource inefficient,” says Peter Rowe, Deep Branch CEO. “It takes about 6 kilograms (kg) of feed to produce one kg of pork. Soy is one of the world’s most widely produced crops but more than 90% of it goes into animal feed.”

It’s not just on land where feed crops are creating problems. Of fish caught around the world, an incredible 25% is processed into fishmeal for the aquaculture, or fish farming, industry. The demand for fishmeal is such that at present it outpaces demand for fish.

Even with an increasing number of people shifting to meat-free diets and more alternatives making headlines, meat production is still expected to double by 2050.

These industries need serious overhauls if they are to sustain into the coming decades. Deep Branch, helped via funding from Innovate UK, is looking to aquaculture as a test bed for sustainable protein production whilst also encouraging CO2 capture.

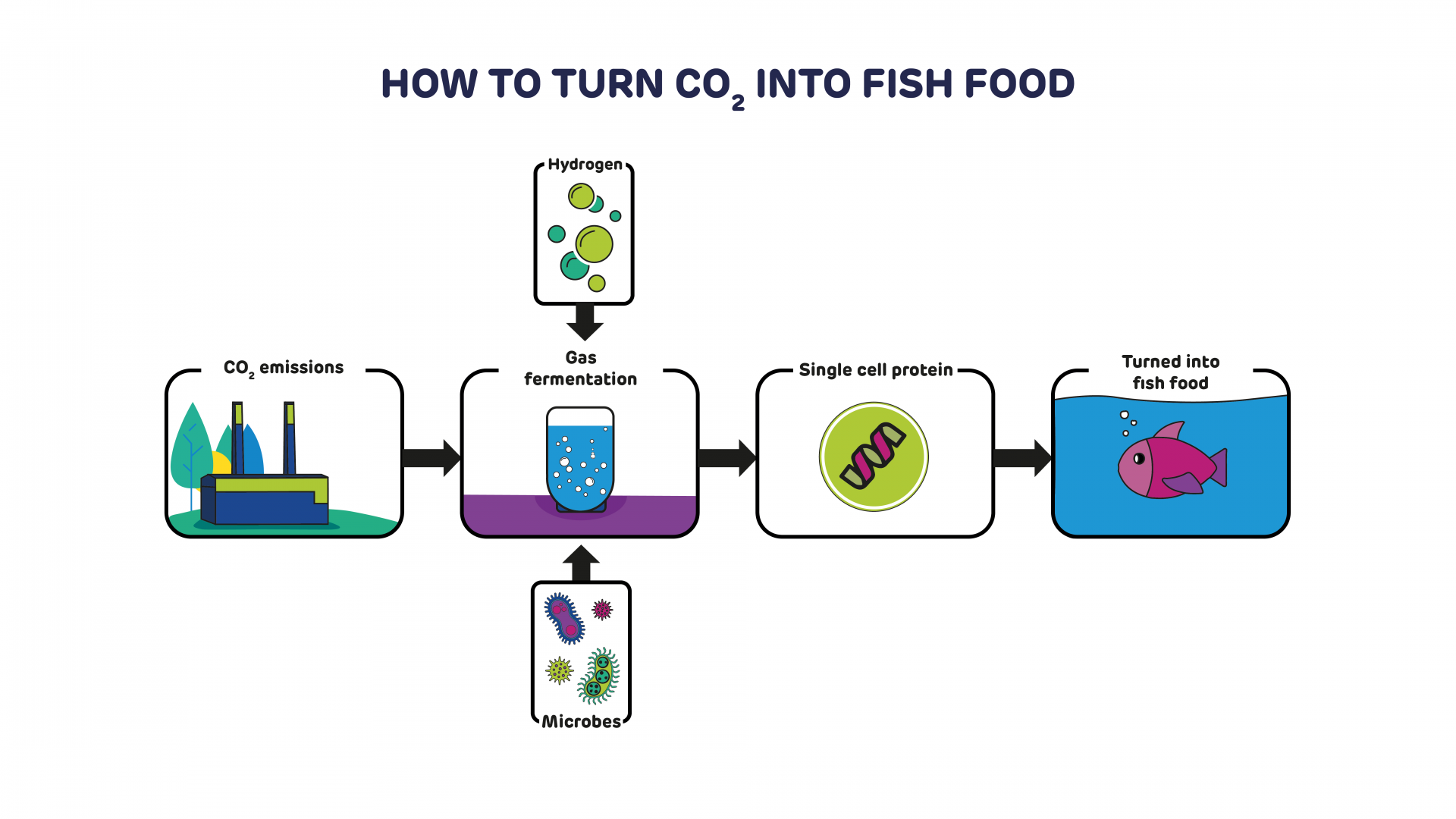

The secret behind Deep Branch’s approach to turning emissions into fish food is a strain of bacteria that feeds on CO2.

The partnership will see Deep Branch connect directly to a source of CO2, with the start-up taking up residence in Drax’s carbon capture usage and storage (CCUS) incubator space. Here, flue gas from one of Drax’s biomass power generation units will be fed into Deep Branch’s system, along with hydrogen, enabling a process known as gas fermentation to take place.

Download graphic: High Res (no logo) High Res (with logo)

“Normally when people think of fermentation, they think about something like wine, where sugar is converted into alcohol with a yeast acting as the biological catalyst,” says Rowe. “Our process, however, uses CO2 and hydrogen instead of sugar. Rather than yeast, our proprietary bacterium acts as the biological catalyst and converts these gases into protein.”

The resulting product is single cell protein, which comes out as a milk-like liquid when harvested. It’s then dried into powder and 70% of what remains are proteins that can be used as a fishmeal replacement.

One of the advantages of Deep Branch’s system is that rather than requiring energy to separate CO2, flue gas can be delivered directly to microbes, which can convert up to 70% of the captured CO2 into proteins. But for such a system to have a real impact it needs to be deployed at scale.

The process has been trialled in labs and proved highly efficient, with ten kg of CO2 producing seven kg of protein. What this new partnership with Drax offers is the opportunity to test Deep Branch’s process and technology at grid-scale. And while Deep Branch is focusing on aquaculture for now, the concept could potentially reach much further through the food chain.

Fish feed

“Because Drax’s biomass units are carbon neutral at the point of generation, the process creates an extremely low-carbon protein,” explains Rowe. “If you divorce the negative environmental impacts of industries like agriculture from its growth then you can provide more whilst impacting less.”

Deployed at global scale the idea of carbon-neutral protein would free up some of the arable land currently being used for soy and other feed crops. It means that as well as cutting the carbon intensity of traditional protein sources, more land would be available for other uses, while helping to halt climate change.

Countries, companies and industries around the world are racing to find ways to reduce their emissions. But looking slightly further down the line there is in fact a grander aim: negative emissions.

Negative emissions technologies (NETs) can actually absorb more carbon dioxide (CO2) from the atmosphere than they emit, and they’re vitally important for avoiding catastrophic, man-made climate change. Without NETs it could be impossible to achieve the Intergovernmental Panel on Climate Change’s ambition of keeping temperatures under 1.5 degrees Celsius above pre-industrial levels.

One example already being implemented is bioenergy with carbon capture and storage (BECCS). It is what its name suggests. Using technologies to capture and store the CO2 generated during the process of energy generation from biomass or organic materials rather than releasing it into the atmosphere.

BECCS holds vast potential in the electricity generation industry. Drax Power Station is currently piloting one form of this technology on one of its biomass units to capture as much as a tonne of CO2 a day. But if it were deployed across all its biomass units, BECCS technology could make it the world’s first negative emissions power station.

Beyond the power industry, however, there’s scope for growth across other industries once the biomass is sourced sustainably. There are already five sites around the world where BECCS is being trialled and implemented at scale, laying the road to negative emissions.

The ethanol production industry is already seeing significant deployment of BECCS, including the largest installation of the technology operating in the world. The Illinois Industrial Carbon Capture and Storage project is part of a corn-to-ethanol plant in the US that has the capacity to capture 1 million tonnes of CO2 every year.

Here, corn is used to create ethanol by fermenting it in an oxygen-deprived environment. This process creates CO2 as a by-product, which is captured and stored permanently in pores within the sandstone of the Illinois Basin under the facility.

Researchers believe with further development the site could capture as much as 250 million tonnes each year.

Concrete is one of the world’s most versatile building materials. As a result it is the second most-consumed material in the world behind water – more than 10 billion tonnes of it is produced every year. However, its key ingredient – cement, which acts as concrete’s binding agent – is made using a hugely carbon-intensive manufacturing process and now accounts for as much as 6% of all global carbon emissions.

The Norcem Cement plant in Brevik, South-East Norway, has been experimenting with using biomass to power the kilns used to create its cement (which must heat ingredients to 1,500 degrees Celsius). Now it’s taking this a step further by becoming part of the country’s ambitious Full Chain CCS project.

The project will see 400,000 tonnes of CO2 captured annually, which will then be transported by ship to a storage site on Norway’s western coast. From here a pipeline will transport the CO2 50 kilometres away and deposit it deep below the North Sea’s bed.

The plan has the potential to work at an even bigger scale. The pipeline will be capable of receiving as much as 4 million tonnes of CO2 per year, meaning it could even import and store carbon from other countries.

Burning waste and growing algae

Burning waste and growing algaeIn a world that seems increasingly unsure how to safely deal with its waste, the idea of incinerating it and making use of the heat this produces seems widely beneficial. But combusting any solid means releasing carbon emissions.

In Japan, however, a biomass-fired waste incineration plant is changing this by being the first in the world to capture its carbon emissions.

To get this project up and running, Toshiba, the firm behind the project, had to overcome unique challenges. For example, waste incineration produces a greater mix of chemicals than in ethanol or power production, including some that are corrosive to the metal pipes normally used in carbon capture.

Now running at commercial scale, the Saga City waste incineration plant isn’t just capturing CO2, it’s also utilising it to cultivate crops at a nearby algae farm. The carbon is being absorbed and used to grow algae for use in commercial scale cosmetic products, such as body and skin lotions.

Carbon isn’t the only thing finding new use at the facility. Reconstituted scrap metal from the plant is being used to make the medals for the 2020 Tokyo Olympics.

The carbon capture system has been operational since 2016 and is capable of capturing 3,000 tonnes of CO2 a year, but it isn’t the region’s first deployments of BECCS.

Fully integrating BECCS into biomass power

Fully integrating BECCS into biomass powerNearby, the Mikawa power plant on the Fukuoka Prefecture, is leading the race in Asia to fully integrate carbon capture technology into a biomass power station.

The 50 MW power station successfully piloted carbon capture in 2009 through a partnership with Toshiba. At the time it was powered by coal, however, in 2017, the plant upgraded to a 100% biomass boiler fuelled by palm kernel shells – a waste product from palm oil extraction mills. Now it’s in the process of ramping up its carbon capture capabilities, with a target of being operational in 2020.

The system – which after Drax will be the second plant in the world to capture carbon using 100% biomass feedstock – will have the capacity to capture more than 50% of the biomass plant’s CO2 emissions, or as much as 180,000 tonnes per year. Japan’s government is now supporting efforts to develop CO2 transportation and potential offshore storage solutions for next year.

BECCS technology has yet to be deployed in the paper industry to the same extent as in other organic-matter-based industries. But with many pulp and paper mills already using by-products, such as hog fuel, in generating power for their sites, it’s a prime area for BECCS growth.

In Saint-Felicien, Quebec, commercial-scale carbon capture technology is being deployed at a pulp mill run by Resolute Forest Products, and, as of March 2019, had a capacity of capturing 11,000 tonnes of CO2 a year. Rather than storage, however, it supplies the carbon to a cucumber-growing greenhouse next door to the mill, as well as supplying enough warm water to meet 25% of the greenhouses’ heating needs.

Both long established biomass-based industries like ethanol and paper, and new sectors like electricity, are now adopting BECCS technology and driving innovation.

The biomass feedstocks involved in BECCS must, however, be sourced sustainably – or else a positive climate impact could be at the expense of environmental degradation elsewhere. ‘It should be possible to expand biomass supply in a sustainable way,’ found a recent ‘Global biomass markets’ report from Ricardo AEA for the UK’s Department for Business, Energy and Industrial Strategy (BEIS).

While it’s still a complex technology to deploy, BECCS is increasingly operating at larger scales and growing to the level needed to seriously reduce industrial CO2 emissions and help to combat climate change.

Cutting carbon emissions is the headline environmental policy for the 195 countries signed up to the Paris Climate Agreement – and so it should be. Decarbonisation is crucial to keeping global warming below 2oC and avoiding or at least mitigating potentially dire consequences for our planet, its people and biodiversity.

However, centuries of pumping out carbon dioxide (CO2) from factories, vehicles and power plants means it’s not enough just to reduce output. Countries must also work on CO2 removal (CDR) from the atmosphere. Implemented at scale, what’s also known as Greenhouse Gas Removal (GGR) could mean a country or facility removing more CO2 than it emits – effectively giving it negative emissions.

Achieving this is not only advantageous to combating climate change, it’s essential. A new report from the Intergovernmental Panel on Climate Change (IPCC) explores 116 scenarios in which global warming is kept to 1.5 oC of pre-industrial levels (more ambitious than the Paris Agreements 2oC). Of these scenarios, 101 use negative emissions technologies (NETs) at a scale of between 100 to 1,000 gigatonnes* over the 21st century.

Given the scale of the ambition, the task of capturing enough carbon to be truly negative will need to rely on many sources. Here are some of the techniques, technologies, and innovations aiming to push the world towards negative emissions.

Weyerhaeuser Nursery, Camden, Alabama

CDR doesn’t have to utilise complex tech and chemistry. The planet’s natural carbon cycle already removes and stores huge amounts of carbon from the atmosphere – primarily through trees. The world’s forests have absorbed as much as 30% of annual global human-generated CO2 emissions over the last few decades.

Regenerating depleted forests (reforestation), planting new forests (afforestation), and protecting and helping existing forests thrive through active management can all contribute to offsetting emissions.

The IPCC report estimates that reforestations and afforestation could potentially capture 0.5 and 3.6 billion tonnes of CO2 a year at a cost of USD$5 to $50 (£3.90 to £39) per metric tonne.

There are potential drawbacks of extensive afforestation. It could compete with food crops, as well as reducing the reflection of heat and light back into space that arid lands currently offer to prevent global warming.

Biomass on its own is an important fuel source in lowering emissions from industries such as power generation. On one hand, it’s created by organic material, which during its lifetime absorbs carbon from the atmosphere (often enough to offset emissions from transportation and combustion). On another, it creates a sustainable market for forestry products, encouraging landowners to responsibly manage forests, which in turn can lead to growing forests and increased CO2 absorption.

But when combined with carbon capture and storage (CCS or CCUS) technology it becomes a negative carbon emissions process, known as BECCS. Drax is partnering with carbon capture company C-Capture in a £400,000 pilot to develop CCS technology, which will remove a tonne of carbon from its operations a day. Combined with the carbon removed by the forests supplying the biomass, it could turn Drax into the world’s first negative emissions power station.

Beyond just storing the captured carbon underground, however, it can be used to create a range of products, locking in and making use of the carbon for much longer.

The IPCC report estimates between 0.5 and 5 billion metric tonnes of carbon could be captured globally this way at a cost of $100 to $200 (£80-160) per metric tonne.

Mangrove roots

It’s not only forests of fast-growing pines or eucalyptus that remove CO2 from the atmosphere. In fact, coastal vegetation such as mangroves, salt marshes and sea grasses suck in and store carbon in soil at a greater rate than plants on land. The carbon stored in these waterside ecosystems is known as ‘blue carbon’.

Human encroachment and development on coastlines has depleted these environments. However, efforts are underway to regenerate and expand these hyper-absorbent ecosystems –turning them into carbon sinks that can remove more emissions from the atmosphere than conventional forests. Apple is currently throwing its financial weight behind a mangrove expansion project in Colombia to try and offset its global operations.

Beyond costal mangroves, the ocean is full of plants that use CO2 to photosynthesise – in fact, the oceans are thought to be one of the world’s largest carbon sinks. But there are some people who think we could enhance marine plants’ absorption abilities.

Eelgrass Bed

One such approach involves injecting iron nutrients into the ocean to prompt a bloom in microscopic plants called phytoplankton, which float in the upper part of the ocean absorbing the CO2 absorbed from the atmosphere. When the plants eventually die they then sink trapping the absorbed carbon on the seabed.

An additional positive effect would be an increase in dimethyl sulphide, which marine plants emit. This could alter the reflectivity of clouds that absorb water from the ocean and further act to cool the earth.

Plants absorbing CO2 through photosynthesis is the most-commonly known part of the carbon cycle, however, rocks also absorb CO2 as they weather and erode.

Plants absorbing CO2 through photosynthesis is the most-commonly known part of the carbon cycle, however, rocks also absorb CO2 as they weather and erode.

The CO2 usually reaches the rock in the form of rain, which absorbs CO2 from the atmosphere as it falls. It then reacts with the rocks, very slowly breaking them down, and forming a bicarbonate that is eventually washed into the ocean, locking the carbon on the seabed.

The problem is it takes a long time. One idea that seeks to use this natural process more effectively is to speed it up by pulverising rocks and spreading the resulting powder over a larger area to absorb more CO2 from rain and air.

Natural rock weathering currently absorbs around 0.3% of global fossil fuel emissions annually, but the IPCC estimates at scale it could capture 2 and 4 billion metric tons at a cost of between $50 and $200 (£39-160) per metric ton. This approach also requires extensive land use and has not been trialled at scale.

Soil is another major carbon sink. Plants and grasses that die and rot store carbon in the soil for long periods. However, modern farming techniques, such as intensive ploughing and fertilisation, causes carbon to be released and oxidised to form CO2.

Adjustments in farming methods could change this and, at scale, make agriculture carbon neutral. Straightforward techniques such as minimising soil disturbance, crop rotation and grassland regeneration could sequester as much as 5 billion tonnes of carbon into the soil annually, according to the IPCC, at potential zero cost.

A challenge to this method is that once soil is saturated it can’t hold any more carbon. That material would also be easily released if methods are not maintained in the future.

A way to super-charge how much carbon soil can store is to add a substance called biochar to the earth. A type of charcoal made by burning biomass, such as wood or farm waste, in the absence of oxygen, biochar can increase the amount of carbon locked into the soil for hundreds or thousands of years. It also helps soil retain water, and reduce methane and nitrogen emissions.

Biochar has only been trialled at a small scale but the IPCC estimates that between 0.5 and 2 billion metric tonnes could be captured annually through this means. However, it predicts a cost of between $30 and $120 (£23-94) per metric tonne. Additionally, producing biochar at scale would require large amounts of biomass that must be sustainably sourced.

CO2 is in the air all around us and so removing it from the atmosphere can effectively take place anywhere. Direct air capture (DAC or DACCS) proposes that the carbon capture and storage technology many power stations are now trialling can be carried out almost anywhere.

Swiss start-up Climeworks is one company attempting to make DAC viable. Its technology works by passing air through a surface that reacts with CO2 to form a compound, but releases the remaining air. The newly formed compound is then heated so the reactive chemical agent can be separated and reused. The CO2 is then stored underground with gas and water where it reacts with basalt and turns to stone in less than two years.

The main challenge for this technique is the cost – between $200 and $600 (£156-468) per metric tonne – and that it requires large amounts of energy, creating further demand for electricity.

Wood pellet storage domes at Drax Power Station, Selby, North Yorkshire

The primary challenge for negative emission technology as a whole is that so few have actually been implemented at a global scale. However, trials are in motion around in the world, including at Drax, to remove emissions and help limit the effects of climate change.

Even if the UK decarbonises heavily across all sectors of the economy by 2050, there’s still projected to be 130 MtCO2 (million tonnes of carbon dioxide) net emissions. But a Royal Academy/Royal Society report released earlier this year was optimistic. It concluded that the country can become net zero and do its part in mitigating man made climate change – with BECCS identified as the negative emissions technology best suited to take the leading role and at least cost.

The UK has come a long way in its efforts to decarbonise. Greenhouse gas emissions last year were 43% below 1990 levels, while increasing renewable electricity generation and a strengthening carbon price means the country could soon go coal-free for an entire summer.

There is still, however, much work needed to reach the UK target of reducing emissions to 20% of 1990 levels by 2050 and meeting the Paris Agreement’s aim of keeping temperature increases below two degrees Celsius. As ambitious as these goals may be, recent research by the Energy Transitions Commission (ETC) believes they can be met by 2050, with the right government policies and action from businesses.

To help to mitigate man made climate change, all industries, across all sectors must cut carbon emissions. It’s a big challenge but a clear first step must be the decarbonisation of electricity generation. This step will enable other industries to reduce their emissions in turn through electrification.

Since 2000 we have been building our experience in decarbonising electrical generation, transforming what was once Western Europe’s largest coal-fired power station into the UK’s biggest decarbonisation project. This puts us in a unique position to offer the leadership and innovation needed – across the electricity industry and other sectors – to reach a zero-carbon world.

The electrification of carbon-intensive sectors, such as transport and heating, will only contribute to reducing overall emissions if the electricity comes from mostly low or zero-carbon sources.

The ETC’s research suggests wind and solar will be capable of providing 85% of the world’s electricity generation by 2050. When these intermittent sources are unable to generate electricity the remaining 15% will come from a combination of nuclear, hydro, biomass and storage (including batteries, pumped storage and new technologies).

In fact, biomass alone could provide as much as half of that 15% but it is critical that this flexible, renewable, low carbon fuel must be sustainably sourced. For the wood biomass we use at Drax Power Station, its sourcing should contribute to growing and healthy forests, which will be another key part of the climate change solution.

Will Gardiner, CEO, Drax Group

At Drax, we have a long history of finding ways to cut emissions and improve the efficiency of our own biomass pellet supply chain, from bigger ships to more efficient rail freight loading and unloading.

The skills and experiences gained from these efforts serve not only to decarbonise our business but will benefit other supply chain-based industries along the path to lower-carbon emissions. More than this, it is far from the only way we are working towards doing this.

One of the biggest hopes for removing carbon from industry lies in carbon capture and storage. We’re leading the charge on bringing this technology to the fore by running a six-month pilot of a Bioenergy Carbon Capture and Storage (BECCS) system, which will capture a tonne of carbon every day from one of our four, 600+ megawatt (MW) biomass units.

Capturing emissions not only further reduces the carbon intensiveness of electricity generators of all kinds, but also opens new revenue streams for businesses through utilising captured carbon. For Drax, BECCS takes us another step towards becoming a carbon negative operation, where we remove more carbon from the atmosphere than we emit. It is also an opportunity to further expand the knowledge and experience of our team and become leading experts in a field which will be essential in meeting climate change goals.

Alongside this, our plans to repower the last of our coal-fired units to highly-efficient combined cycle gas turbines (CCGT) and build four, rapid-response open cycle gas turbines (OCGT) will give the electricity system the flexibility needed to support more intermittent renewable sources. The abilities of gas plant in balancing and system services can help to complete the journey away from coal before 2025. In subsequent decades, gas can play a pivotal role assisting the transition to a zero-carbon power system.

Alongside this, our plans to repower the last of our coal-fired units to highly-efficient combined cycle gas turbines (CCGT) and build four, rapid-response open cycle gas turbines (OCGT) will give the electricity system the flexibility needed to support more intermittent renewable sources. The abilities of gas plant in balancing and system services can help to complete the journey away from coal before 2025. In subsequent decades, gas can play a pivotal role assisting the transition to a zero-carbon power system.

Our retail businesses, Haven Power and Opus Energy, also allow us to help companies and the public sector outside of electricity generation to reduce their carbon footprint. Beyond just supplying renewable electricity, we’re also looking at ways through closer customer partnerships to help businesses leverage new technologies to use electricity more efficiently and in turn lower their costs.

Reaching a zero-carbon future is a monumental task for electricity producers that depends on innovative thinking and new technologies. We have the experience in developing transformative ideas and making them a reality – all of which will be essential in guiding us into a brighter, more stable, decarbonised future.

The combination of a heatwave and an entertaining world cup campaign put big demands on Great Britain’s beer supplies this summer. But European-wide carbon dioxide (CO2) shortages put a hold on that celebratory atmosphere as word spread that a lack of bubbles could result in the country running out of beer.

The drinks business managed to hold out, but the threat of long term CO2 shortages still lingers over the continent. One possible – and surprising – solution could lie in electricity generation, thanks to the capturing and storing of its carbon emissions.

Carbon capture and storage (CCS) is one of the key technologies in need of development to allow nations to meet their Paris Agreement goals. It has the potential to stop massive amounts of emissions entering the atmosphere, but it also raises the question: what happens to all that carbon once it’s captured?

Drax recently met with the British Beer & Pub Association to discuss using some of the carbon it plans to capture in its upcoming trial of Bioenergy Carbon Capture and Storage (BECCS) to keep the fizz in drinks.

It’s a novel solution to a potential problem, but it’s just one of the many emerging possibilities being developed around the world.

Carbon capture is all about reducing carbon footprints – a phrase energy company NRG interpreted quite literally by creating ‘The Shoe Without A Footprint’. The white trainer was created to showcase the abilities of carbon capture, use and storage (CCuS) and is made of 75% material produced from captured emissions that have been turned into polymers, a molecular structure similar to plastics.

Only five pairs of the sneakers were created as part of NRG’s Carbon XPrize competition to find uses for captured carbon. However, they remain symbolic of the versatility offered by captured and stored carbon and its potential to contribute to the manufacture of everyday objects.

Finding an alternative to plastics is one of the key ways of facilitating a move away from global dependencies on crude oil. Sustainable materials company Newlight uses captured CO2 or methane emissions to create a bioplastic called AirCarbon – a thermopolymer, which means it can be melted down and reshaped.

The company has teamed up with IKEA, which will buy 50% of the 23,000 tonnes of bioplastic Newlight’s plant produces per year. It’s part of the Swedish furniture giant’s efforts to increase the amount of recycled materials it uses and means upcycled carbon could soon be appearing in millions of homes around the world.

If the shoes people walk around on can be made from captured carbon, so too can the cities they walk within. Making concrete is a notoriously dirty process. Cement, the main binding agent in concrete, is thought to contribute to as much as 5% of the world’s greenhouse gas emissions, but this could change thanks to clever use and implementation of carbon capture technology.

At one level, CCS can be introduced to capture emissions from the manufacturing process. On another, the CO2 captured can be used as a raw material from which to create the concrete, effectively ‘locking in’ carbon and storing it for the long term.

Teams of engineers, material scientists and economists at UCLA who have worked on the problem for 30 years have succeeded in creating construction materials from CO2 emissions in lab conditions using 3D printing technology. Now it’s just a matter of scaling it up to industrial usage.

Carbon nanotubes are stronger than steel but lighter than aluminium, which makes them a hugely useful material. They’re currently used in jets, sports cars and even in industrial structures, but producing them can be expensive and, until recently, could not utilise CO2 for manufacture. A team from George Washington University is changing that.

Its C2CNT technology splits captured CO2 into oxygen and carbon in a molten carbonate bath using electrolysis. From here the carbon is repurposed into carbon nanotubes at a high rate and lower cost than previous methods.

Transportation is one of the major emitters of carbon around the world, so any way it can be reduced or re-used in this field will be a huge positive. Carbon recycling company LanzaTech has developed a way to do this via a process that uses anaerobic bacteria to ferment emissions into cleaner chemicals and fuels.

Its first facility, opening this year in China, will create fuel-grade bioethanol that can be blended with gasoline to create vehicle fuel, or even converted into jet fuel with 65% lower greenhouse gas emissions.

Aviation, too, can benefit from carbon recycling through the creation of synthetic crude oil and gas using CO2. Technology company Sunfire is developing processes that combine hydrogen (set to become a major part of industry and transport) and biogenic CO2, (emissions from natural sources), to create synthetic hydrocarbons that could fuel planes.

Earth isn’t the only place humans are innovating around carbon capture – at least, right now. With the race to send men and women to Mars stepping up, the challenges of dealing with its inhospitable atmosphere (which is 95% CO2) and ensuring a minimal human impact to the planet are becoming more acute. Carbon capture and use presents an opportunity to tackle both.

Californian company Opus 12 has developed a device that recycles CO2 from ambient air and industrial emissions and turns it into fuels and chemicals using only electricity and water. The device has the CO2 conversion power of 37,000 trees (or 64 football fields of dense forest) packed into the volume of a suitcase, and can convert CO2 into 16 different products.

In the long-term, the technology might provide critical services for human colonies on the Red Planet by capturing and using CO2 from the atmosphere or any future Mars-based factories. The Opus 12 device can also use ice (buried on the planet in places that could be accessible to astronauts) to convert Mars CO2 into plastic to make bricks and tools, methane that can form rocket fuel, and feedstocks for microbes to create medicine or food.

Many of these technologies are in their infancy, but the possibilities they present are very real. In fact, Drax’s upcoming trial of BECCS will see it capture and store as much as a tonne of carbon every day.

The proliferation of this technology in industry and electricity production – and the resultant increase in captured carbon – will help encourage more companies to see CO2 emissions as an opportunity for revenue while helping countries meet their Paris Agreement emissions goals.

This story was updated in June 2018 following the announcement of Drax’s pilot BECCS project.

Is there a way to generate electricity not only with no emissions, but with negative emissions?

It’s an idea that, after decades of being reliant on coal had seemed almost impossible. But as Drax has shown by announcing a pilot of the first bioenergy carbon capture storage (BECCS) project of its kind in Europe, it might not be impossible for much longer.

A few years on from the historic Paris Agreement – which sets a target of keeping global temperature rise below two degrees Celsius – innovative solutions for reducing emissions are critical. Among these, few are more promising than BECCS.

It sounds like a straightforward solution – capture carbon emissions and lock them up hundreds of metres underground or turn the carbon into useful products – but the result could be game-changing: generating electricity with negative emissions.

Carbon capture and storage (CCS) technology works by trapping the carbon dioxide (CO2) emitted after a fuel source has been used and moving it to safe storage – often in depleted oil and gas reservoirs underground.

There are a number of CCS technologies available but one of the simplest is oxyfuel combustion. Fuel such as coal, gas or biomass, is burnt in a high oxygen environment and CO2 – rather than carbon (C) or carbon monoxide (CO) – is produced. Other impurities are removed and the resulting pure CO2 is compressed to form a liquid. This CO2 can then be transported via pipeline to its designated storage space, normally hundreds of metres underground.

The UK is well-placed to benefit from the technology thanks to the North Sea – which has enough space to store the EU’s carbon emissions for the next 100 years.

It’s a technology that can drastically reduce the emissions from fossil fuel use, but how can it be used to produce negative emissions?

Biomass, such as sustainably sourced compressed wood pellets, is a renewable fuel – the CO2 captured as part of its life in the forest is equal to the emissions it releases when used to generate electricity. When coupled with CCS, the overall process of biomass electricity generation removes more CO2 from the atmosphere than it releases.

A report published by the Energy Technology Institute (ETI) looking at the UK has suggested that by the 2050s BECCS could deliver roughly 55 million tonnes of net negative emissions a year – approximately half the nation’s emissions target.

It’s not the only body heralding it as a necessary step for the future. The Intergovernmental Panel on Climate Change (IPCC), stated in a 2014 report that keeping global warming below two degrees Celsius would be difficult if BECCS had limited deployment.

Support is widespread, but for it to lead to a practical future, BECCS needs suitable support and investment.

Mills such as Morehouse BioEnergy manufacture compressed wood pellets – a sustainably-sourced fuel for BECCS power plants of the future.

There are only a handful of CCS projects in operation or under construction across the world and many simply re-use rather than capture the CO2. Part of the reason is cost. It’s estimated that optimal CCS technology can cost about as much as the power station itself to install, and running it can consume up to 20% of a station’s power output. This means more fuel is needed to produce the same amount of power compared to a conventional power plant of similar efficiency.

Without government support, it remains a prohibitively expensive solution for many power generators. With government support in the form of multi-decade contracts, large CCS or BECCS plants could leverage economies of scale. They could deliver energy companies and their shareholders a return on the investments in the long-term.

Past plans by Drax could have put the company on a timeline towards becoming the world’s first large scale negative emitter of CO2. It would have achieved it firstly with the construction of a CCS power station at its Selby, North Yorkshire site.

The 428 MW White Rose power station was to be fuelled by a mixture of coal and biomass and once in operation, could have paved the way for similar facilities elsewhere as carbon capture technology improved and costs came down, but unfortunately the project never went ahead.

There are some positive signs that carbon capture technologies are developing around the world. The first ‘clean coal’ power station became operational in the US earlier this month – and a second CCS plant is on the way. A UK-backed carbon capture and use (CCU) project in India recently opened at a chemicals factory, involving the capture of emissions for use in the manufacturing process.

Back in the UK, where the government outlined plans to end coal-fired power generation by 2025, carbon capture power stations must become financially competitive if they are to become a major part of the country’s low carbon future. But if the world is to achieve the targets agreed in Paris and pursue a cleaner future, negative emissions are a must, and BECCS remains a leading technology to help achieve it.