The self-driving car is a sci-fi stalwart. The blend of familiar vehicle combined with advanced-artificial intelligence makes it a perfect symbol of a not-too-distant future which is fast approaching. But what a sci-fi movie is unlikely to show is a self-driving car pulling over for half an hour to fill its tank or recharge its batteries.

As autonomous vehicles gradually inch into our everyday life, the question of how they will be powered arises, as does whether they will be capable of refuelling or recharging without a helping human hand.

With governments around the world setting ambitious targets for the phasing out of diesel and petrol car sales, it’s safe to assume the driverless vehicles of the future will be electric.

But will they be able to charge themselves? More than that, how would a large influx of these cars coming onto our roads affect our national electricity demand and emissions?

How will driverless cars charge themselves?

Development is already well underway to bring human-free charging to the auto world with a variety of approaches being trialled:

-

Robotic charging points

The most straightforward way to enable self-driving electric vehicles (EVs) to charge themselves is through updating existing infrastructure. Adding on robotic limbs to standard charge points would be one way of removing the need for human hands. Tesla previously demonstrated a porotype of a snake-like arm that plugs into its vehicle’s charge points that does exactly this.

-

Under-car charging

Easier than flailing robotic arms is the idea of charging cars from underneath a parked car. Unsurprisingly, Tesla has patented a version of the technology, too.

While building the technology into the ground adds complications, it could potentially allow cars to be charged while moving – which is exactly what one road in Sweden is doing.

The two kilometre stretch outside Stockholm features a metal track that an arm under EVs can connect to – much like a Scalextric track. The route is divided into 50-metre sections which are electrified separately as vehicles travel over them. Sweden is now planning to roll the concept out nationally.

-

Wireless charging

A step up from under-car charging, wireless technology uses inductive charging rather than physically connecting with the car, and can be installed into parking spaces, or be set into the tarmac.

The problem with this is it’s not as fast as directly connecting with the car. However, implemented at scale, entire roads could constantly charge vehicles when they need a top up.

It would mean that rather than taking EVs home and plugging them in, the city and roads themselves would charge it. But even the idea of keeping a car at home might fade as cars become increasingly autonomous.

Rethinking vehicle ownership

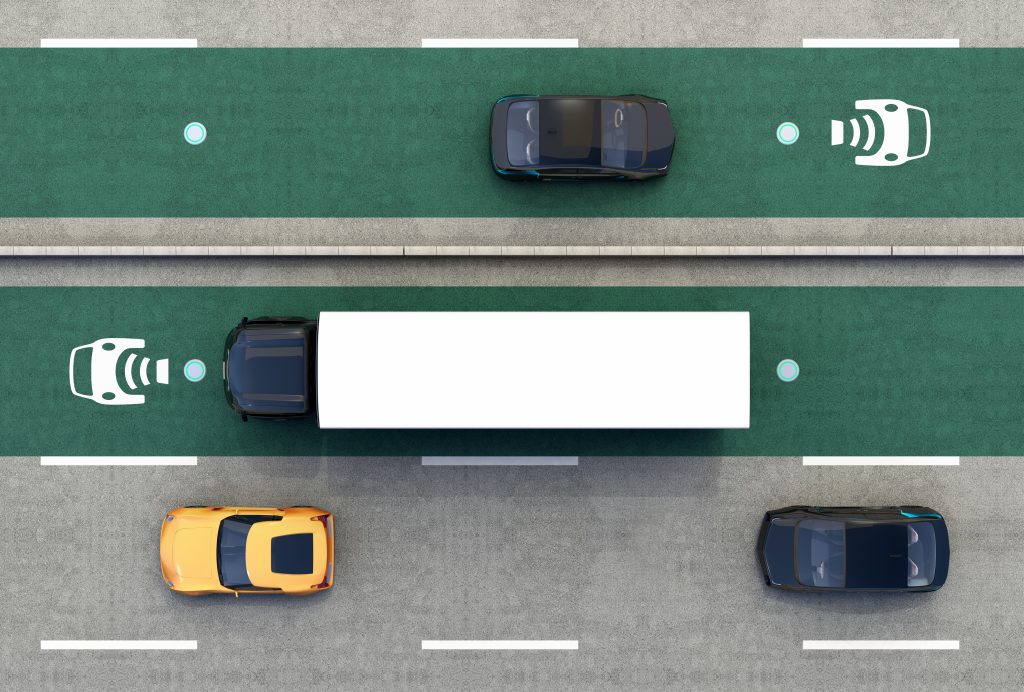

As more of the world’s population move to cities and they grow increasingly congested, car ownership is declining – a trend being further fueled by ridesharing services, like Uber, Lyft and Didi Chuxing in China.

And as services such as these continue to grow in popularity, it could point to a future where rather than owning self-driving cars, they will be shared among urban populations. Lyft Strategist Raj Kapoor suggested the reduced cost of maintenance of shared EVs would make rides cheap enough for the average person to ride in every day.

This could result in fewer cars on the roads as intelligent systems allow them to coordinate sharing across the population, which in turn could lead to a reduction in demand for charging. However, the more intense computing power needed in self-driving vehicles means they will each use more electricity than a standard EV.

Powering these sufficiently will depend on technology and coordination, rather than producing significantly more electricity.

Smarter cars, smarter cities, smarter electricity

Changes in car ownership could mean the total reshaping of cities. If cars don’t need to park for long periods of times on central roadsides and in garages, vehicles could instead be stored on the outskirts of cities when demand for transport is low and make their way into towns as people begin commuting.

This vision of cars, seemingly independently rolling around cities to exactly where they’re needed, depends not on a single car reacting to a single command, but to a network of data points connected to almost every aspect of a city. More than this, there’s even potential these cars could provide power as well as use it.

Vehicle-to-gird (V2G) technology means they can essentially act as batteries and return electricity to the grid when needed. A fully connected network of autonomous cars, linked to buildings, cities and entire electricity networks could be used to help meet demand on a local or national scale, helping avoid fossil fuel usage at times of stress.

While increasing EV usage will likely contribute to an increase in electricity demand, self-driving, smarter vehicles will ensure power is used at efficiently as possible and reduce the number of cars drawing electricity from the grid.

It ultimately means global investment in the charging infrastructure that will create a more connected and economical transport system, which will make widespread EV and autonomous cars a reality.