Children visiting the Skylark Nature Reserve on April 24th built the huge replica airship at a workshop run by Drax Power Station held in tribute to the R33, which took flight for the first time in March 1919 after being built in nearby Barlow.

The last of three giant airships constructed in the area, the so-called ‘gas bag’ was flown by the Royal Naval Air Service and used for a decade in both military and civilian tasks.

The site of the workshop where the R33 was designed and built is now known as the Barlow Mound, which is close to Drax Power Station and the 350-acre nature reserve created by the company.

Drax organised the event as part of its ongoing commitment to switch young people on to science, technology, engineering and maths (STEM).

Drax Power CEO Andy Koss said:

“The centenary of the R33 gave us an opportunity to celebrate an exciting part of our local heritage.

“Through events like these we can also inspire more children to consider studying STEM subjects and develop the skills businesses like ours need to continue to grow, helping to build a strong regional economy.”

As well as building the giant replica, weaving recyclable willow into six separate sections before combining it into one huge model, the young airship makers also paced out the entire 196 metres of the real R33’s length to give them an idea of its sheer scale.

Noah Thornton, aged seven, said:

“It must have been massive. Our model will be nine metres and that’s big. It’s taken a lot of work but it’s been good fun and I now know more about airships.”

Eight-year-old Mia Socha added:

“I built the second part of the model and weaving it all was the hardest part. It looks really good now it’s all put together. It’s been a great day.”

And seven-year-old Reuben Delaney said:

“All I knew about airships was that they flew but I know a lot more now and our model looks brilliant.”

As well as encouraging STEM learning, Drax is committed to developing the next generation of engineers – it has doubled the number of apprentices it is recruiting in 2019 compared to just two years ago.

The firm has also invested in a partnership with a number of local schools to enable them to build and race electric cars on the streets of Hull at the end of the month, again to promote greater engagement with STEM skills.

ENDS

Media contacts:

Mark Duffell

MCD Communications Ltd

E: mduffell@mcdco.uk

T: 07969080272

Jessica Gorton

Drax Group Press Officer

E: jessica.gorton@drax.com

T: 07712677177

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

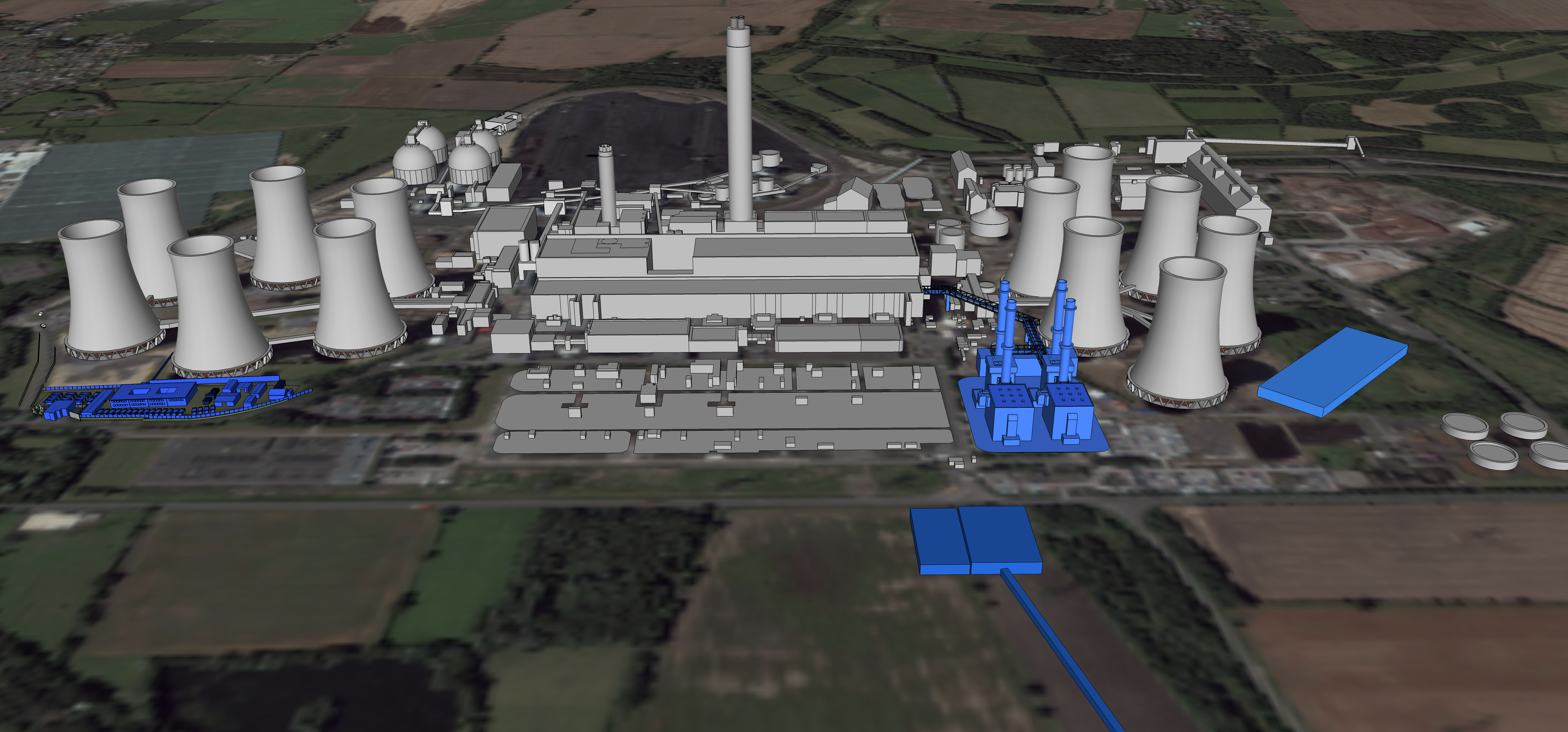

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies six percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

B2B supply:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com