-

Drax Group, Equinor and National Grid Ventures announce new zero carbon partnership

-

Commitment marks first significant response from industry following Committee on Climate Change’s Net Zero report

-

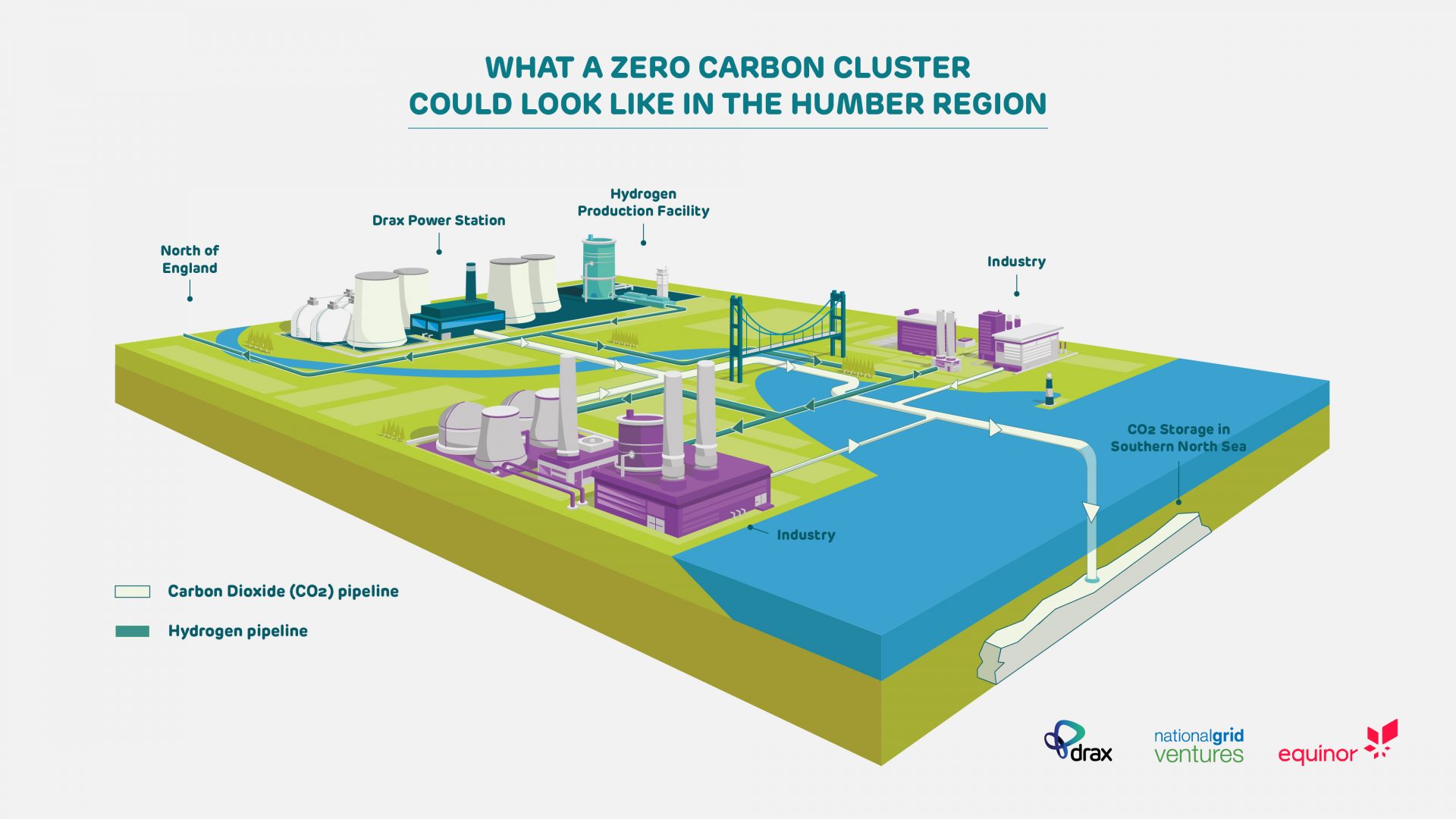

Plan could deliver the UK’s first zero carbon cluster and help position Great Britain at the heart of the global energy revolution

This is the first significant action from industry since the UK Committee on Climate Change (CCC) recently published its Net Zero report, which found that CCUS and hydrogen technology developed in regional industrial clusters is essential if Great Britain is going to achieve a ‘net zero’ carbon economy by 2050.

The partnership could lead to the Humber becoming the world’s first net zero carbon region and home to a new world leading hydrogen economy.

Commenting on the partnership, Will Gardiner, Drax Group CEO, said:

“The Committee on Climate Change was clear – the UK needs both bioenergy with CCS and hydrogen production at scale by 2030 to achieve a ‘net zero’ carbon economy. This partnership is committed to meeting this challenge putting Great Britain at the heart of the global energy revolution.

“With Drax’s carbon negative power station, the Humber region could lead the world in new technologies that can deliver for the climate and the economy, helping to create a cleaner environment for future generations whilst creating new jobs and export opportunities for British businesses.

“We’re excited to be working with National Grid Ventures and Equinor on this project – for decades the Humber has been a strategically important industrial cluster for the UK – it has the skills, industrial capability as well as offshore storage to transform itself into a cutting-edge low carbon hub.”

Drax Power Station, North Yorkshire. Click to view/download.

Irene Rummelhoff, Equinor’s executive vice president for marketing, midstream and processing, said:

“As a global leader in CCS and a major gas supplier to the UK for many decades, we are committed to helping shape sustainable solutions for a low carbon future.

“We are pleased to be partnering with Drax and National Grid Ventures in looking at how the Humber region can be a launch pad for wider decarbonisation in the UK economy and be an example for others to learn from. Globally we must see substantial decarbonisation of industry and energy in the years ahead, and we believe CCS and hydrogen must play a significant role in this.”

Equinor’s Snøhvit offshore development in the Barents Sea. Click to view/download.

Jon Butterworth, Chief Operating Officer, Global Transmission, for National Grid Ventures, said:

“We all agree that we must act now to start delivering a ‘net-zero’ carbon economy. That’s why we’re delighted to be working together with Equinor and Drax. This is a project of great potential for the UK and the Humber region and we look forward to leveraging our skills and expertise to enable this transition.

“We have seen rapid progress in decarbonising energy through established technologies such as wind power, solar and electricity interconnectors. CCUS and hydrogen create a new pathway to greater decarbonisation of the energy system and provide a platform for decarbonising other areas of our economy, which will be to the benefit of current and future generations.”

National Grid pipelines. Click to view/download.

The three companies will work together to:

- Explore the opportunity to scale-up the innovative bioenergy carbon capture and storage (BECCS) pilot project at the Drax Power Station in order to create the world’s first carbon negative power station in the 2020s.

- Explore the potential development of a large-scale hydrogen demonstrator within the Drax site by as early as the mid-2020s – in line with the CCC’s recommendation that hydrogen should be produced at scale in at least one industrial cluster by 2030.

- Explore the strategic opportunities in developing a cutting-edge hydrogen economy in the region.

Equinor’s Tjeldbergodden industrial facility at Nordmøre, Norway, has a methanol plant, a gas receiving terminal and an air separation plant. Click to view/download.

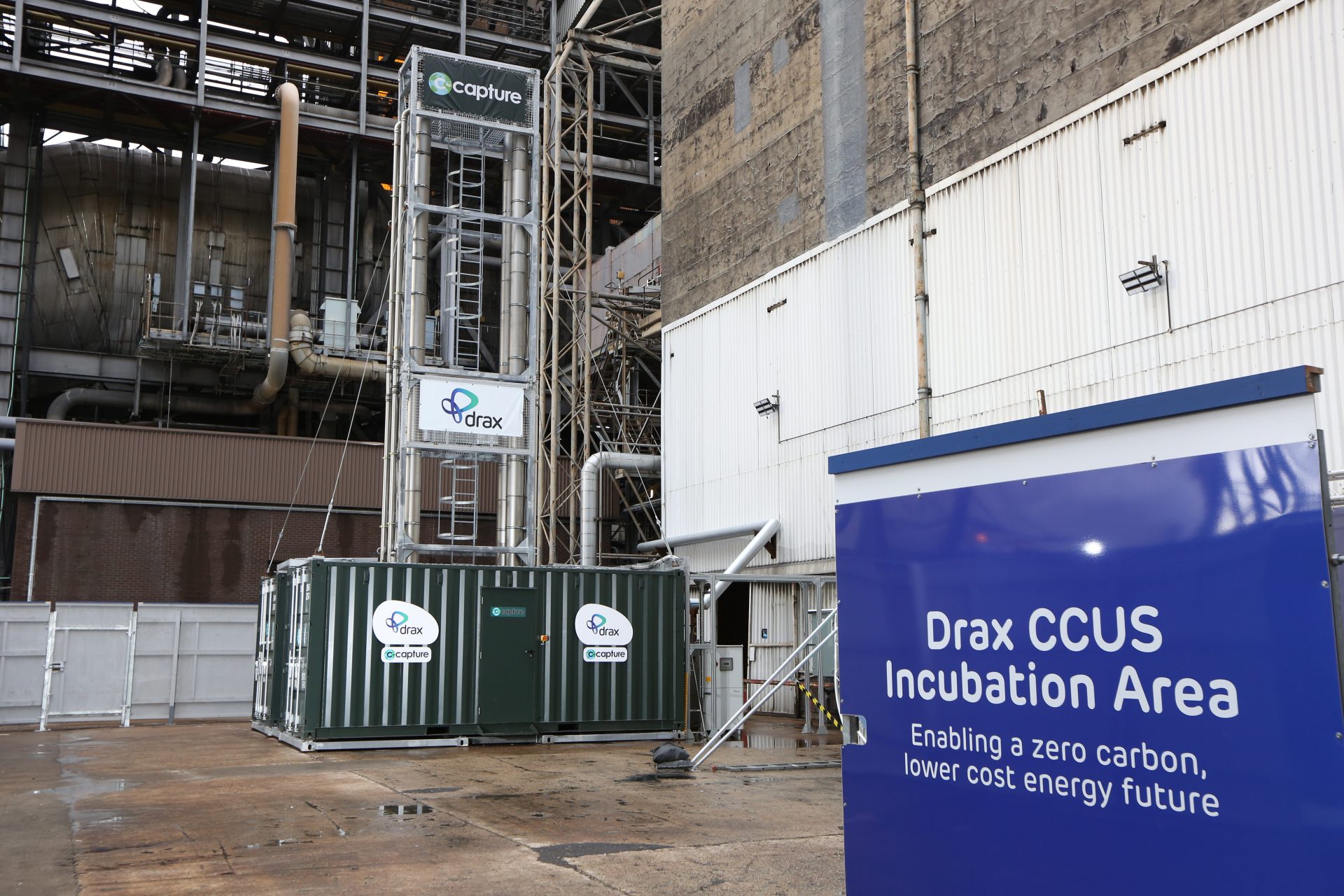

Drax Power Station in North Yorkshire is already capturing a tonne of carbon dioxide a day from its innovative bioenergy carbon capture and storage (BECCS) pilot project. If it is scaled up it could serve as the ‘anchor’ for a regional CCUS network capturing millions of tonnes of carbon each year from nearby industrial emitters.

Energy and Clean Growth Minister Claire Perry visited the Drax Power Station BECCS pilot project in November 2018. Click to view/download.

The consortium has the collective expertise and credibility to deliver on the CCC recommendation for large-scale trials of hydrogen, development of CCS transport and storage infrastructure, and the deployment of BECCS at scale.

A study outlining the technical, economic and societal opportunities for CCUS and hydrogen in the Humber region will be published by the partners later this year.

ENDS

Media contacts

Ali Lewis

Drax Group Head of Media & PR

E: ali.lewis@drax.com

T: +44 7712 670 888

Eskil Eriksen

Equinor Communication Manager

E: eseri@equinor.com

T: +47 9588 2534

Sara Revell

National Grid Ventures Press Officer

E: sara.revell@nationalgrid.com

T: +44 1926 653962

Editor’s Notes

- The consortium will work with partners in the public and private sectors to harness the Humber’s key strengths and capabilities and help it become the world’s first net-zero carbon industrial cluster. These include:

- Its position as the largest industrial cluster in the UK by emissions;

- Its proximity to Drax Power Station, which could become the single largest source of ‘negative emissions’ in the UK through its BECCS project;

- The extensive engineering design work previously undertaken to develop a large-scale carbon transportation and storage network in the region as part of the White Rose CCS project;

- Its proximity to the Endurance and Bunter aquifer in the North Sea, a large natural CO2 store which could be used by the Humber and other nearby industrial clusters to permanently store their carbon emissions.

- Drax announced in February that is has started to capture carbon dioxide from its BECCS pilot project using technology developed by Leeds University spin-out company C-Capture. This is the first-time carbon dioxide has been captured from the combustion of a 100% biomass feedstock anywhere in the world.

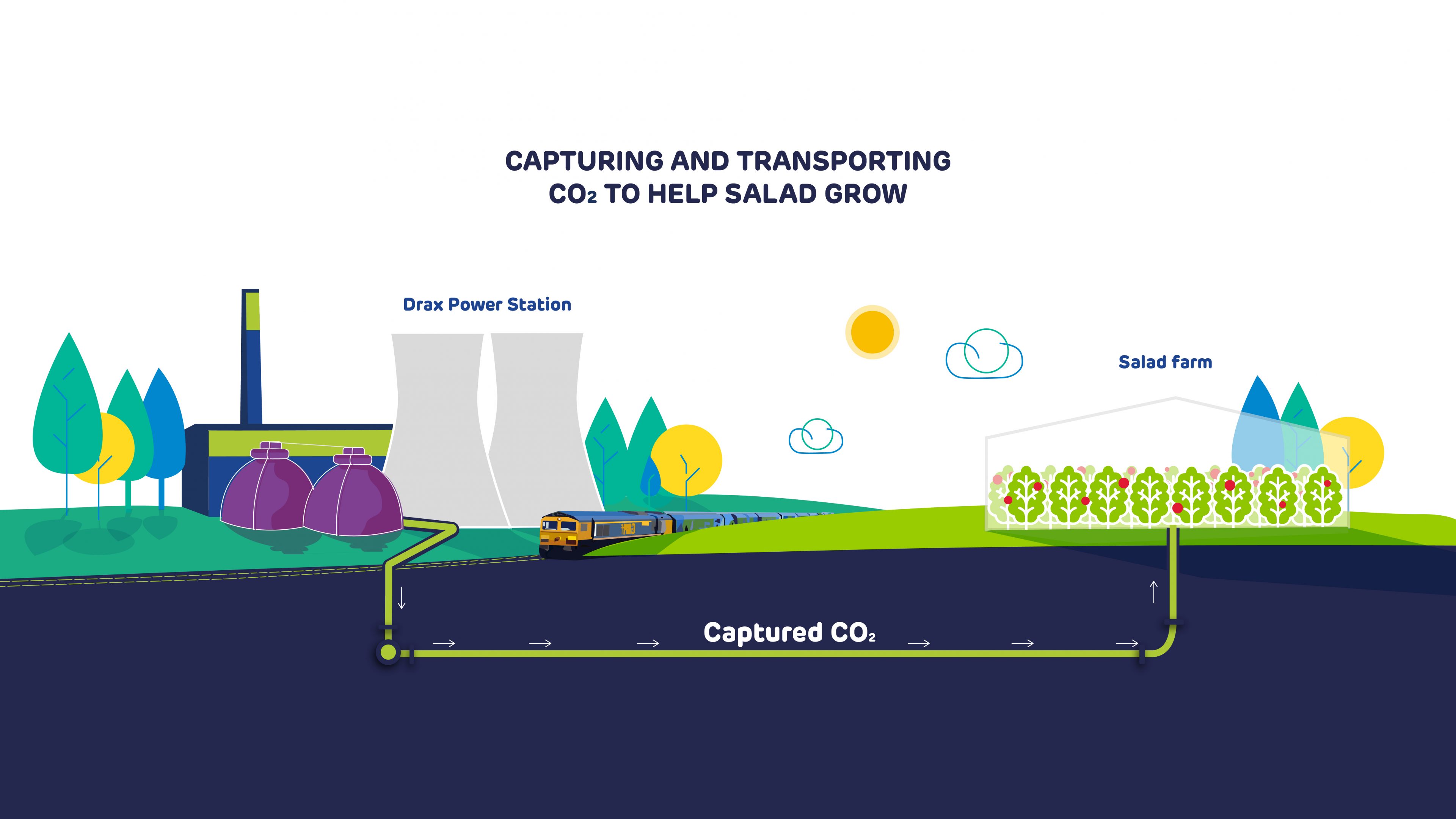

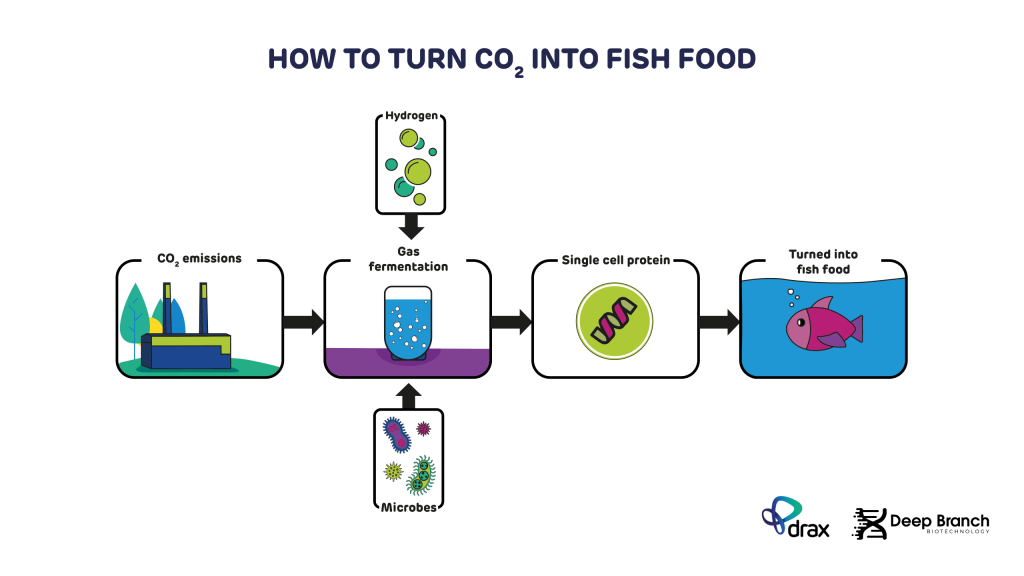

- Since starting its innovative BECCS pilot project Drax has been talking to several industries about using its CO2 in their processes. This could be to produce concrete, within the food and drinks industry or creating synthetic fuels to use in hard-to-decarbonise sectors like aviation. It has set up a dedicated ‘Incubation Area’ at the power station that will give other technology companies the opportunity to test their processes on its carbon dioxide.

- Drax Power Station is already the largest decarbonisation project in Europe having converted two thirds of its generating units to use biomass instead of coal.

- If the BECCS pilot can be scaled up to deliver negative emissions, Drax Power Station would be helping to remove the gases that cause global warming from the atmosphere at the same time as electricity is produced.

- The Committee on Climate Change’s Net Zero report states that BECCS could generate up to 173 TWh of electricity by 2050, capturing up to 51 Mt CO2 – around half of the remaining carbon in the economy that the UK will need to capture to become ‘net zero’.

- Today Drax is capturing a tonne of carbon dioxide a day from its pilot – once scaled up it would be capturing 40,000 tonnes of carbon a day from its four biomass generating units. That’s at a 90% capture rate.

- The CCC’s Net Zero report also identified that at least one of the UK’s CCUS regional clusters should involve substantial production of low-carbon hydrogen by 2030 to stay ‘on track’ for net zero. It also recommends that infrastructure development for CCUS should start as early as possible, in all regional clusters with large industrial emissions.

- The recently published H21 North of England study has also shown that up to 3.7 million homes as well as other industrial processes could be converted from natural gas to hydrogen to meet the UK’s climate change targets

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies six percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

B2B supply:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com

About Equinor

Equinor is transitioning into a broad energy company committed to long term value creation in a low carbon future inspired by its vision of shaping the future of energy. Equinor continues to pursue its strategy of always safe, high value and low carbon through developing and maximising the value of its unique Norwegian continental shelf position, its international oil and gas business, its manufacturing and trading activities and its growing new energy business.

Equinor is a leading provider of oil and gas to the UK and has three offshore wind projects in the UK: Sheringham Shoal, Dudgeon and Hywind Scotland, the world’s first floating offshore wind farm. It is developing three further offshore wind projects at Dogger Bank which would make up a further 3.6 GW of capacity. It is also developing the Mariner and Rosebank projects on the UK Continental Shelf and is an active explorer with five exploration wells being drilled in 2019.

Equinor has more than 20 years’ experience with CO2 storage in both offshore and onshore locations. It is currently storing up to 1.8 million tonnes per year, equivalent to the emissions from 850,000 cars, and is the operator for Northern Lights, the transport and permanent storage section of Norway’s full-scale demonstration project for CCS.

In addition, Equinor has extensive expertise across the hydrogen supply chain, including through producing hydrogen for its methanol plant at Tjeldbergodden in Norway, and is engaged in feasibility studies to evaluate the conversion of a combined cycle power station from natural gas to hydrogen fuel.

About National Grid Ventures

National Grid Ventures is part of National Grid plc, one of the world’s largest investor-owned energy companies. Separate from National Grid’s core regulated businesses, NGV develops, operates and invests in energy projects, technologies and partnerships to accelerate the development of a clean energy future for consumers. NGV’s existing portfolio includes four gigawatts of operational electricity interconnector capacity connecting the UK with neighbouring markets, which enables the delivery of cleaner, more secure and more affordable energy. NGV is also constructing three more interconnectors to France, Norway and Denmark and has recently announced an agreement to acquire Geronimo Energy, a leading US-based renewable energy developer.

Selby District Councillor and Executive member Chris Pearson said:

Selby District Councillor and Executive member Chris Pearson said: