Renewable energy leader Drax Group (Drax) and Smart Green Shipping are partnering on a groundbreaking project, to develop and use innovative wind-assisted ‘FastRig’ technology, which will be used to help decarbonise the shipping sector.

The project will see Drax inject £1m into the initiative, matched by funding from the UK Government’s Clean Maritime Demonstration Competition (CMDC) grant, which will see Smart Green Shipping’s, lightweight, retractable wingsail, installed on a vessel, with a view to demonstrating how the technology can reduce fuel consumption and resulting emissions by up to 30% per year.

Smart Green Shipping is currently undertaking sea trials of FastRig on one of Nuclear Transport Solutions’ specialist vessels, the Pacific Grebe – a purpose-built ship designed to carry nuclear cargo around the world safely. The sea trials will conclude by the end of October and will provide Smart Green Shipping with accurate, independently verified performance data.

The greenhouse gas (GHG) emissions from shipping contribute around 3% of all global emissions, having risen 20% over the last decade. An earlier feasibility study conducted in partnership with Drax demonstrated potential fuel savings on ships equipped with FastRig of up to 30% per year on transatlantic routes.

If the latest demonstration is successful, work to install the technology on a commercial biomass vessel can begin, helping to decarbonise this hard-to-abate sector. The technology could also prove vital to further reducing supply chain emissions from the bulk transport of Drax’s sustainable biomass, which is used to produce around 8% of Britain’s renewable power.

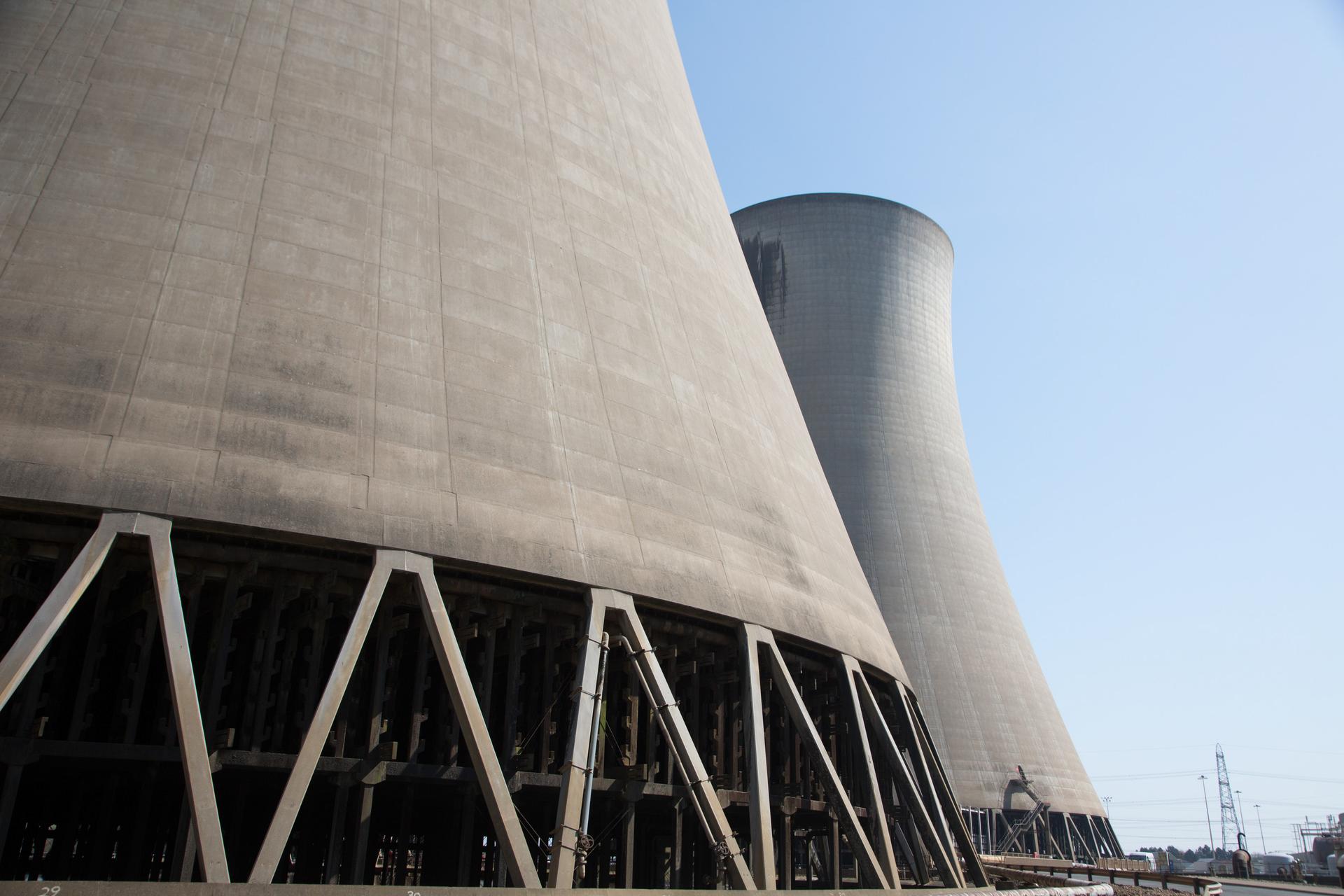

Drax aims to become a carbon negative company by 2030 by installing Bioenergy with Carbon Capture and Storage (BECCS) at Drax Power Station, in Yorkshire. The power station has already been transformed by using sustainable biomass instead of coal, and the application of BECCS could enable Drax to further reduce its emissions by permanently removing up to eight million tonnes of CO2 from the atmosphere each year.

Drax’s investment in the project will also be used to develop Smart Green Shipping’s suite of wind-assist solutions. This includes FastRoute, an industry-first digital system co-created with the University of Southampton, that combines artificial intelligence with high-performance computing to analyse weather data and optimise routes for ships equipped to harness wind power. Using historical and forecast weather data, FastRoute accurately predicts how FastRig will perform, optimising journeys for FastRig-enabled ships and giving investors confidence in fuel savings. Research shows that optimised weather routes significantly reduce fuel usage and GHG emissions.

Diane Gilpin, CEO and founder of Smart Green Shipping said: “Wind is abundant, free, and exclusively available to any ship equipped to use it. Modern 21st century easily retrofittable wing sails lower the cost of propelling ships, which reduces the dependency on commodity-based fuels – whether fossil or alternative fuels – and improves supply chain certainty. Smart Green Shipping shares a joint mission with Drax Group to use renewables to move renewables. We are immensely grateful for the support from Drax Group to create seamless and easy-to-access wind solutions for cargo owners and ship owners. The first commercial installation of FastRig is incredibly exciting and an important milestone as we derisk the transition to wind for the whole shipping ecosystem.”

Miguel Veiga Pestana, Chief Sustainability Officer at Drax said: “Smart Green Shipping’s technology represents a landmark moment for the maritime energy transition and Drax is proud to provide this funding, which re-affirms our commitment to becoming a carbon-negative business by 2030. We look forward to continuing our longstanding partnership as we work together on this exciting project, which could allow us to significantly reduce emissions from the shipping of sustainable biomass, and help to decarbonise a crucial part of our global supply chain.”

Maritime Minister, Mike Kane said: “Reducing shipping emissions is vital if we’re going to decarbonise the sector and achieve our mission of becoming a Clean Energy Superpower. It’s fantastic to see Government funding making a difference, and we will continue to support UK industry to deliver a cleaner, greener sector and develop the smart technologies of the future.”

ENDS

Media contact:

Kieran Wilson

E: kieran.wilson@drax.com

T: 07729092807

Image credit: NTS/Smart Green Shipping

Editor notes

- Drax plans to install Bioenergy with Carbon Capture and Storage at its power station in Yorkshire by 2030, allowing Drax to remove millions of tonnes of carbon dioxide from the atmosphere whilst producing renewable power and creating up to 10,000 jobs.

- Drax Power Station plays an important role in UK energy security, contributing around 4% of the country’s total power and 8% of its renewable electricity.

- Leading climate scientists and energy experts at the UK Climate Change Committee, UN IPCC and National Grid all recognise that BECCS is essential for reaching net zero.

- The UN Conference on Trade and Development (UNCTAD) stated in its review of Maritime Transport 2023 that maritime trade is expected to grow 2.4% in 2023 and more than 2% between 2024 and 2028.

- The report also states that without action, emissions could reach 130% of their 2008 levels by 2050.

- Drax reports its supply chain emissions in its Annual Report, which is independently audited.

About Smart Green Shipping:

Smart Green Shipping unlocks wind power for the shipping industry by building and financing autonomous, retrofittable wind technologies to help reduce carbon emissions by 30%. The first product in the suite, FastRig – a 100% recyclable wingsail – is undergoing at-sea trials with NTS in October 2024 in a project part-funded by the UK Government. Smart Green Shipping works closely within the shipping ecosystem, including cargo owners Drax, shipowners MOL, Ultrabulk, NTS and has received support and investment from Scottish Enterprise. Its technical team comprises Humphreys Yacht Design, Houlder, Malin Group, Caley Ocean Systems, Argo Engineering, Lloyd’s Register and the University of Southampton.

About Drax:

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Power generation:

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

Pellet production and supply:

The Group has 19 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Customers:

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com