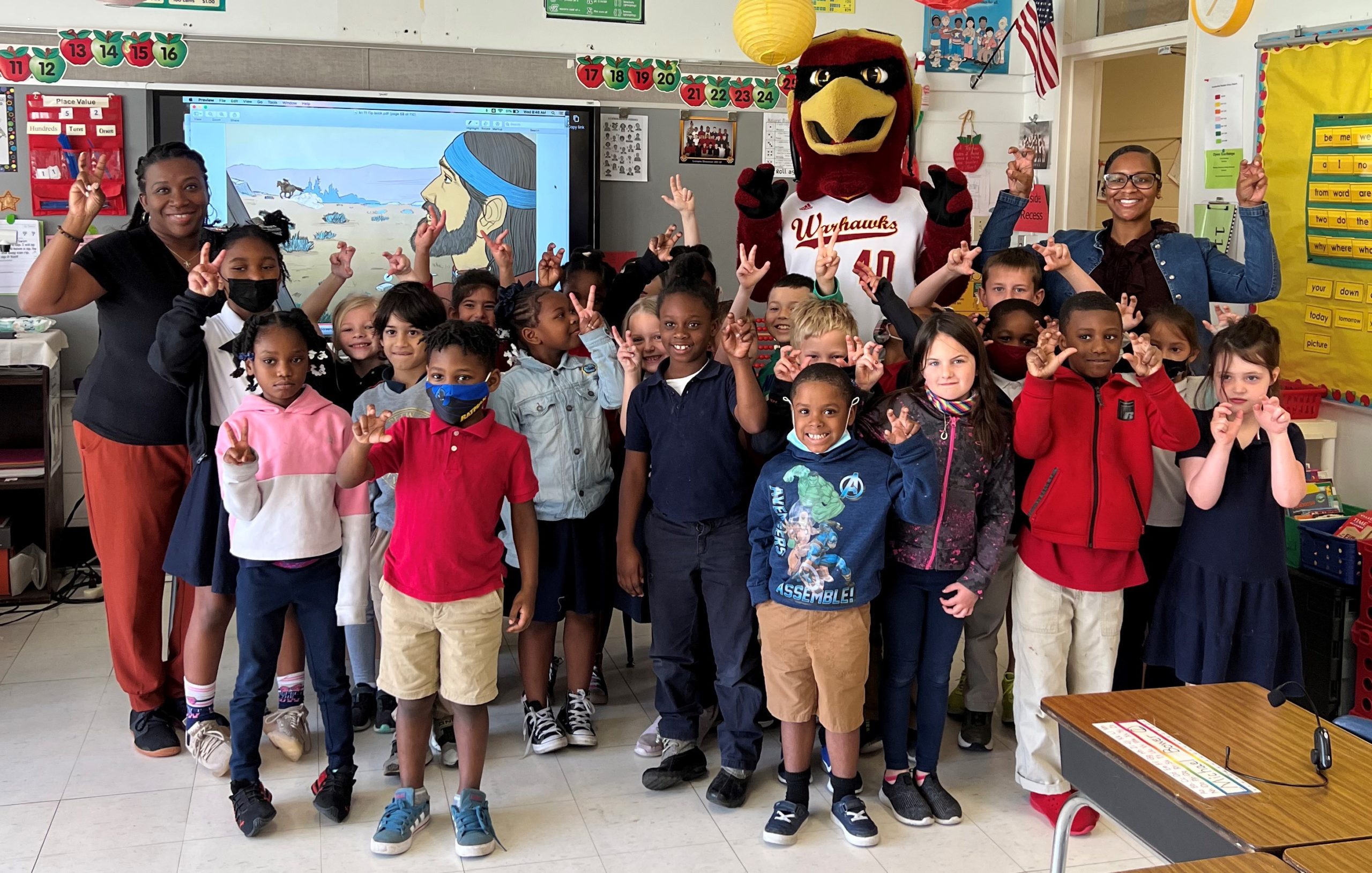

Drax’s Classroom of the Month for April was awarded to first-grade pupils at Lexington Elementary School in Monroe for making consistent progress on their academic skills and working hard to achieve their goals.

Their teacher Becky Zeno said: “The kids were so excited to be awarded Classroom of the Month and meet Ace the Warhawk. The program helps to motivate them by showing them the options that are available to them within their community. The kids will remember Ace, and that he represents the university. The game tickets they received will give them an opportunity to see the campus, which will hopefully spark their imagination and get them thinking about attending college in the future.”

The program has been developed by Drax in partnership with the University of Louisiana at Monroe (ULM) to inspire local students to start thinking about higher education and what they can achieve, as part of the energy company’s ongoing commitment to supporting education in the communities local to its operations.

A different class each month is awarded ‘Classroom of the Month’ by Drax and receives a visit from ULM representatives to reward the pupils for their hard work and show them some of the options available in their hometown as they advance through school.

Drax has arranged for representatives from the University’s athletics department to visit the schools to talk to the students, raise awareness of the college and answer any questions they might have. The students also receive two tickets each to a Warhawk football, basketball, or baseball game and meet Ace, the team mascot.

Drew Bellipanni, Partnership Services Co-ordinator at ULM, said:

“This program is a chance to give back to our local schools and teachers who have worked hard throughout the pandemic to continue teaching our children. We hope Classroom of the Month will motivate students to continue studying as well as see what college has to offer.”

Executive Vice President of Drax’s Pellet Operations, Matt White, said:

“It’s so important that the next generation has equal access to education. Even though these children are in the early stages of their school careers, we hope this program will inspire them by showing them what opportunities are available to them in the future.”

Drax is committed to supporting the communities local to its operations through a variety of measures that include sponsoring educational programs and providing support in times of crisis, including during the Covid-19 pandemic and recent natural disasters such as Hurricane Ida.

ENDS

Media contacts:

Annmarie Sartor

Communications Officer

E: [email protected]

T: 318-801-0046

About Drax

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using Bioenergy with Carbon Capture and Storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Power generation:

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4Mt of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

Pellet production and supply:

The Group has 17 operational pellet plants and developments with nameplate capacity of 4.6Mt, which will increase to c.5Mt once developments are complete.

Drax is targeting 8Mt of production capacity by 2030, which will require the development of over 3Mt of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet mills supply around 30% of the biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses.

Customers:

Drax is the largest supplier of renewable electricity to UK businesses, supplying 100% renewable electricity as standard to more than 370,000 sites through Drax and Opus Energy.

It offers a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

The three satellite plants in Arkansas are expected to produce a total of around 120,000 tonnes of sustainable biomass pellets a year from sawmill residues. This supports Drax’s plans to double its pellet production capacity to 8 million tonnes by 2030 to meet its own requirements, as well as its customers’ needs in Europe and Asia, amid an expected increase in global demand for the low-carbon fuel.

The three satellite plants in Arkansas are expected to produce a total of around 120,000 tonnes of sustainable biomass pellets a year from sawmill residues. This supports Drax’s plans to double its pellet production capacity to 8 million tonnes by 2030 to meet its own requirements, as well as its customers’ needs in Europe and Asia, amid an expected increase in global demand for the low-carbon fuel.