Drax enters formal discussions with UK Government on large-scale Power BECCS

Baringa’s research shows that by 2027, peak demand for GB electricity will increase by 4GW but at the same time the imminent closure of coal, older gas generation and nuclear power stations will remove up to 6.3GW of secure capacity from the grid.

This will mean that the dispatchable capacity which supports GB energy security will fall from 93% to 85% at times of peak demand, increasing the risk of a supply shortfall. The system will need to rely on other forms of capacity, such as electricity interconnectors and intermittent renewable generation like wind or solar, to make up the 15% difference at times of peak demand, or steps may need to be taken to reduce consumption such as through voluntary demand reduction or forced turndown.

Drax’s power station in Yorkshire is currently the largest provider of dispatchable power to the GB electricity system, as well as being one of the only renewable sources of secure supply. Its renewable biomass generation provides 2.6GW of electricity, supplying millions of homes and businesses with dispatchable, reliable power.

Whilst Drax welcomed the Government’s support for CCS in the recent Budget, it needs its BECCS project to gain Track 1 status, without which, Drax Power Station may become unviable and unable to contribute secure power at a time of such critical need. Until it receives this clarity, Drax has taken the decision to pause it’s multi-million-pound investment programme into the BECCS project at Drax Power Station.

At times with the tightest margins, Drax’s biomass units provide up to 11% of total GB electricity generation and up to 70% of the renewable generation. The loss of Drax’s and other biomass units from the GB electricity system would further reduce the country’s dispatchable capacity to 80% of peak demand (from the already forecasted fall to 85%), increasing reliance on gas and power imports, generation from intermittent renewables, and increasing costs for consumers.

“Whilst we welcome the Government’s ambition to invest billions in carbon capture and storage, we need a firm commitment to BECCS before we commit to investing £2bn into installing this technology at Drax Power Station.

“Until we have this clarity, we are pausing our multi-million pound investment programme in the UK BECCS project and urge Government to use the planned announcement at the end of the month to outline their support for this. Any further delays to this project could impact the UK’s security of supply, net zero and levelling-up ambitions and the viability of Drax Power Station.”

The research also found that by 2027 no established technology can feasibly replace the security of supply provided by Drax’s 2.6GW of biomass capacity, without significantly increasing carbon emissions and relying more on imported fossil fuel from Europe.

It goes on to state that meeting decarbonisation targets without the carbon removals provided by Drax’s BECCS units will be more expensive and difficult and would require accelerating decarbonisation in challenging sectors such as heating, industry and road transport.

The report concludes that it is more cost effective and lower risk to keep existing biomass open than to build additional new build or retrofit gas CCS capacity.

ENDS

Chris Mostyn, Head of Media Relations & PR

E: [email protected]

T: 07548 838896

Editor’s Notes:

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 19 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

“The IPCC AR6 Synthesis report has reaffirmed the important role that bioenergy with carbon capture and storage (BECCS) will play in mitigating the climate crisis.

“There is now growing international scientific consensus that all pathways that limit global warming to 1.5C or 2C must involve substantial levels of carbon removal technologies like BECCS.

“Drax aims to become a global leader in BECCS and over recent months international interest in pioneering the technology has grown because of its ability to deliver reliable renewable power and carbon removals, strengthen energy security, create jobs and support climate efforts. We also hope to create the world’s largest engineered carbon removals project at our Yorkshire power station but by the end of this month we must have a firm commitment for this from Government by including it as a track-1 project.”

Drax’s BECCS project will be instrumental in delivering UK security of supply, net zero and levelling-up and will be critical to providing certainty as to the future of Drax Power Station.

Drax welcomes the announcement in the Budget of the investment in domestic carbon capture and looks forward to more detail being provided at the end of March.

Through its use of sustainable biomass Drax Power Station already provides millions of homes and businesses across the UK with secure, renewable power and when delivered, BECCS at Drax will be the largest carbon removals project in the world, playing a critical role in enabling the Government to hit its challenging and legally binding net zero commitments. The construction and operation of the project will create and support up to 10,000 jobs, add £700m to UK GDP and ensure that the country can pioneer BECCS at scale, right in the heart of Yorkshire.

Whilst today’s Budget referenced plans to invest billions in carbon capture and storage, Government has not yet provided the clear, tangible support for BECCS which Drax needs to progress development of the £2bn project.Drax’s North Yorkshire power station could deliver carbon removals at scale from 2027, while generating secure, renewable and affordable electricity.

“The UK Government has in Yorkshire a clear opportunity to turn this country into the world leader in carbon removals technology. Whilst we welcome the Government’s ambition to invest billions in carbon capture and storage, we need them to provide us with a firm commitment to BECCS before we invest £2bn in this UK project.

“It is critical that in the planned announcement at the end of the month Government outlines further support for BECCS because this project will be instrumental in delivering security of supply, net zero and levelling-up and providing certainty as to the future of Drax Power Station.

“In order for the UK to be at the forefront of the green arms race, Government must quickly lay out a detailed, timed and funded plan which offers renewable energy companies like Drax the confidence to continue to invest in this country. Over recent months international interest in pioneering BECCS has grown and we are increasingly excited about the opportunities to deploy BECCS in the US and are currently screening over 10 potential new projects there.”

Earlier this month, MPs and business leaders from across the North of England wrote to the Prime Minister and Chancellor and urged them to “show support for scaling up carbon capture solutions in our region” and commit to the East Coast Cluster, including the opportunity to announce BECCS at Drax as a Track 1 project.

A recent poll run by Focaldata* also revealed that 77% of voters across Yorkshire and the Humber want the Government to back Drax’s plans for BECCS at Drax Power Station.

The poll also showed over 80% of local voters believe it is important that the Government delivers on its legal obligation to make the UK economy net zero by 2050 – with over a third of people saying this task is vital.

ENDS

Andy Low

Media Manager

E: [email protected]

T: 07841 068 415

* Polling commissioned by Drax Group was run using Focaldata, a research and consumer insight platform, and commissioned by Drax. It was carried out between 24 Feb 2023 and 26 Feb 2023 from a sample size of 1,011 across Yorkshire and the Humber.

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 18 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

The Foundation is a key part of Drax’s community strategy, which is focussed on ensuring that the business delivers a positive impact in the communities where it operates.

Drax Foundation will fund initiatives that support education and skills development in Science Technology Engineering and Maths (STEM), as well as those that improve green spaces and enhance biodiversity within local communities. Funding will be available for organisations ranging from smaller community-led projects to larger grants of £50,000 for established non-profit organizations.

Priority will be given to organisations that deliver programmes for under-served and under-represented groups, advance gender equality and support indigenous communities.

Organisations and initiatives that meet Drax’s funding and selection criteria are encouraged to visit www.drax.com/community to learn more about the Foundation and submit an initial expression of interest.

“Launching the Drax Foundation is the start of an exciting new chapter in how we deliver positive social impact in the communities where we operate. Our ambition is to better support diverse organisations who are working hard to create the next generation of STEM students as well as those enhancing local green spaces and biodiversity.

“We are passionate about giving back to the communities we operate in and we are proud of our past philanthropic work. Alongside the new Foundation, and as part of our new community strategy, we are also going to be funding energy efficiency measures for community organisations in the UK, supporting foodbanks around the world and expanding our Communities in Crisis Fund. Combined this is a step change in the support we deliver for people, nature and the climate.”

This outlines how the renewable energy company is implementing its new approach to communities and it will also ensure that as the company grows it has an established platform to roll out and support local organisations.

ENDS

Andy Low

Media Manager

E: [email protected]

T: 07841 068 415

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 18 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

The Alliance is a group of over 120 global CEOs who work together to tackle the climate emergency, reduce the CO2 emissions their businesses produce and inspire other organisations to do the same.

Will’s membership of the Alliance is in recognition of Drax’s ambition of becoming a carbon negative company by 2030 and the anticipated role the company will play in delivering the carbon removals technology that will be critical in limiting global warming to 1.5C or 2C.

He will also be able to share with other Alliance members his experience of delivering a reduction in the business’ carbon emissions from power generation and how Drax is positioning itself to become a world leader in sustainable biomass and developing new carbon removal technologies.

Drax aspires to lead the world in engineered carbon removals through the deployment of bioenergy with carbon capture and storage (BECCS). Once operational, BECCS will generate dispatchable, renewable power while permanently removing carbon from the atmosphere.

“This is a pivotal period to join the World Economic Forum’s Alliance of CEO Climate Leaders and I am excited to work closely with the WEF and other senior leaders to tackle the climate crisis. I’m looking forward to sharing Drax’s expertise with other Alliance members as well as learning from other companies and sectors as to how we can further innovate and reduce our emissions.

“Drax’s purpose is to enable a zero carbon, lower cost energy future and this aligns with the Alliance’s goal of taking bold climate action. In the coming years, the planet will need more renewable energy, more flexible energy systems to make the best use of intermittent wind and solar energy, and crucially, greenhouse gas removal technologies, like Bioenergy with Carbon Capture and Storage.”

“We are delighted that Will has joined us as a member of the Alliance of CEO Climate Leaders. Drax’s commitment to using science-based targets to reduce its carbon emissions and lead the world in the development of BECCS will help inspire other organisations to take positive steps to develop and deploy the technologies needed to tackle the climate crisis. We are looking forward to working with Will and the wider Drax team over the coming years.”

Scientists from the UN’s IPCC have said that carbon removals from BECCS are needed to address the climate crisis and limit global warming to 1.5C above pre-industrial levels. The first state of carbon dioxide removal report, led by the University of Oxford, argues that all pathways that limit warming to 1.5C or 2C involve substantial levels of carbon dioxide removals between 2020 and 2100, ranging from 450 to 1,100 GtCO2.

Drax anticipates that there is strong potential for growth in the carbon removals delivered through BECCS and by 2030, its plans for the UK and North America could remove 12MtCO2 permanently from the atmosphere each year.

ENDS

Andy Low

Media Manager

E: [email protected]

T: 07841 068 415

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 18 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

Academics from Imperial College London for Drax Electric Insights, commissioned via Imperial Consultants, analysed the data which highlights the turbulence that Britain’s electricity system has endured amid an unprecedented year for the energy industry.

Renewable power sources – wind, solar, biomass and hydro – generated 40% of the country’s electricity in 2022 – up from 35% in 2021, helping to cut CO2 emissions from the power sector by 2.7 million tonnes compared to the previous year. Overall generation from renewables has more than quadrupled over the last decade.

At one stage during May, renewables provided 72.8% of power to the grid whilst wind farms generated a landmark 20GW of electricity for the first time – the maximum output from wind is now up by a third compared to four years ago.

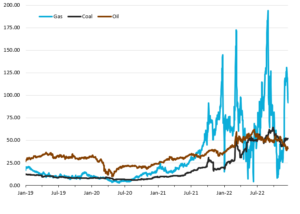

Despite the record supply of cheap renewable electricity, the unprecedented rise in the cost of gas following Russia’s invasion of Ukraine sent power prices to a new all-time high. The fossil fuel supplied 42% of the country’s power this year, its largest share of the fuel mix since 2016. Britain is on course to have annual average wholesale price above £200 per MWh for the first time ever in 2022 – up from £113 the year before. This is nearly six times higher than the cost of electricity in 2020 (£34 per MWh).

The price (£/MWh) of fossil fuels over the last three years, relative to their averages from 2010-19

“This has been a year like no other for the energy industry. The public are feeling the pain of high gas prices on their energy bills even though renewables are providing the grid with more cheap, green electricity than ever before.

“The lesson from 2022 is that we need to break our addiction to fossil fuels once and for all if we want lower cost and more secure energy supplies. If we had not invested in wind, solar and biomass over the last decade our energy bills would have been even higher, as would the risk of blackouts over winter.

“The energy crisis cannot be solved by increasing our reliance on gas imported from abroad. We need to turbocharge our investment in clean energy technologies to become Europe’s renewable electricity powerhouse, which will cut fuel bills at home and bring money into the economy by exporting power to our neighbouring countries.”

For the first time in more than a decade, Britain is a net exporter of electricity to its European neighbours. Electricity exports quadrupled from last year to 17.2 TWh of electricity – generating around £3.1bn for the UK economy. The country exported a net total of 1.9TWh, representing a dramatic swing in power trading from the previous year when Britain instead imported a net total of 22.9TWh.

“Drax plays a critical role in supporting the UK energy system, generating more renewable power by output than any other company.

“We can accelerate and strengthen Britain’s long-term energy security by ending our reliance on expensive, imported fossil fuels and instead increase investment in homegrown renewables, and innovative green technologies such as bioenergy with carbon capture and storage (BECCS) and pumped storage hydro.”

Drax is the UK’s biggest renewable power producer by output, generating enough renewable electricity from biomass and hydro for around 5 million homes – producing as much as 20% of the country’s renewable electricity during times of peak demand in 2022.

Drax plans to invest billions of pounds expanding its pumped hydro storage capacity at its Cruachan power station in Scotland and deploying BECCS at its power station in North Yorkshire, to permanently remove 8million tonnes of carbon dioxide from the atmosphere each year by 2030, whilst generating the reliable, renewable power the country needs.

ENDS

Aidan Kerr

Media Manager

E: [email protected]

T: 07849090368

Ali Lewis

Head of Media & PR

E: [email protected]

T: 07712 670 888

Some key records from the data:

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 19 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

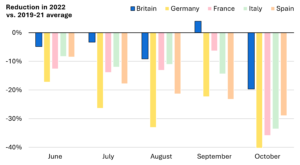

The independent analysis by academics from Imperial College London for Drax Electric Insights, commissioned via Imperial Consultants, shows that the UK’s gas reduction year-on-year was outpaced by Germany, France, Italy, and Spain – with demand for gas actually rising in Britain in September compared to previous years.

Change in natural gas consumption versus the previous three years in UK and comparable European countries. Data covers all sectors excluding power generation and are not adjusted for weather differences.

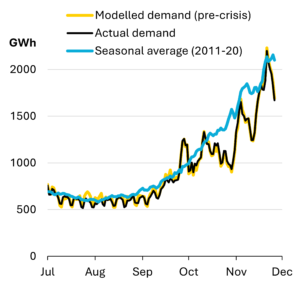

What reduction there was in gas use in the UK was attributable to unseasonably warm weather rather than people adjusting their behaviour. The analysis for Drax Electric Insights showed that from September, through to end of November, Britain’s gas demand was just 0.3% lower than would have been expected pre-energy crisis, when accounting for weather anomalies.

Daily natural gas consumption in UK versus expectations. The blue line shows the seasonal average for all end users except power generation over 10 years to 2020. The yellow line adjusts for weather, showing what demand would be with pre-crisis behaviour. The black line shows actual consumption.

“The UK is an outlier on the world stage, showing no signs of reducing its appetite for gas during a time of dramatically higher prices.

“If temperatures continue to drop during the festive season, managing the energy crisis will be both more difficult and expensive unless people and businesses break their addiction to gas. Turning the thermostat down by just 1°C would save households up to £200 a year on their energy bills and save the UK from importing 50TWh of natural gas over the winter – cutting the cost of the government’s Energy Price Guarantee by £3bn.”

On the continent, national governments have introduced demand reduction measures alongside information campaigns to inspire the public and businesses to act. In Germany, public buildings have turned down their thermostats to 19°C and outside illuminated advertising must be turned off between 10pm until 6am.

The UK Government has now launched a public information campaign on how people can claim financial support this winter alongside more technical advice on how to reduce energy use while still keeping warm, such as reconfiguring boiler settings. This followed the Chancellor announcing a further £6bn to insulate homes and upgrade boilers.

“As a result of Russia’s war in Ukraine the UK’s energy system is under considerable strain this winter and the combination of rising inflation and gas prices has put most household budgets under pressure.

“Britain’s long-term energy security will be strengthened by ending our reliance on expensive imported fossil fuels such as gas and instead increasing investment in homegrown renewables, and innovative green technologies such as bioenergy with carbon capture and storage (BECCS) and pumped storage hydro.”

Drax is the UK’s biggest renewable power producer by output, generating enough renewable electricity from biomass and hydro for around 5 million homes.

It plans to invest billions of pounds expanding its pumped hydro storage capacity at its Cruachan power station in Scotland and also deploying BECCS at its power station in North Yorkshire, to permanently remove 8million tonnes of carbon dioxide from the atmosphere each year by 2030.

ENDS

Aidan Kerr

Media Manager

E: [email protected]

T: 07849090368

Ali Lewis

Head of Media & PR

E: [email protected]

T: 07712 670 888

A copy of the Drax Electric Insights Q3 2022 report is available by clicking here.

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using bioenergy with carbon capture and storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4 million tonnes of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

The Group has 18 operational pellet plants and developments with nameplate production capacity of around 5 million tonnes a year.

Drax is targeting 8 million tonnes of production capacity by 2030, which will require the development of over 3 million tonnes of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet plants supply biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses, and also to customers in Europe and Asia.

Drax supplies renewable electricity to UK businesses, offering a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com

“This report by Jonathon Porritt and an independent panel of experts convened by the Forum for the Future confirms that bioenergy with carbon capture and storage (BECCS) will play a key role in averting the climate catastrophe. The report shows BECCS can be done well, and at scale, so that it delivers positive outcomes for the climate, nature and people. As a company with ambitions to lead the world in this critical carbon removal technology, we are excited about the possibilities our BECCS projects can bring to the forests and communities where we operate, as well as the role they will play in addressing the climate crisis.

“Drax welcomes constructive input and challenge on BECCS and we want to continue working with stakeholders to ensure that BECCS is done well and delivered to the highest standards, using strict governance and forest monitoring to ensure positive outcomes.

“BECCS is the only technology available which can permanently remove millions of tonnes of carbon dioxide from the atmosphere whilst generating the reliable, renewable power decarbonising economies need. It also has the potential to kickstart a whole new sector of the economy, creating thousands of jobs in communities which need them.

“We look forward to using the report to create a blueprint for how to do BECCS well. We will publish a full response to the report’s recommendations in due course.”

View the full report here.