Four weeks after passing the Inflation Reduction Act, President Biden gathered a crowd of 1500 activists, CEOs, politicians, and celebrities on the South Lawn of the White House to mark his most significant political win to date – ushering into law the largest programme of clean energy investment in history.

The Inflation Reduction Act comprises an eye watering $370 billion to kickstart investment in technologies like carbon removals and renewables. According to researchers at Princeton University, it will reduce America’s emissions by more than 6 billion tonnes by 2030 while incentivising around 120GW of clean energy projects each year. Goldman Sachs estimates it could spur as much as $11 trillion in infrastructure investment by 2050.

Biden’s approach has turned heads overseas. For businesses, including my own, the investment opportunities are transformative for both companies and the climate. At Drax, we are pioneering bioenergy with carbon capture and storage, or BECCS – a technology that generates renewable power while removing carbon dioxide from the atmosphere. We have now selected our first two sites in the US, which will remove 6 million tonnes of carbon from atmosphere each year by 2030, and we have a further 9 sites in development. The provisions in the Inflation Reduction Act, namely that to award companies that capture and store carbon dioxide with an $85 per ton credit, make the US an attractive place to be.

Governments have been far less enthusiastic about the legislation, driven by a concern that the lure of Biden’s tax incentives will syphon away domestic industries. The UK has been particularly robust in its response, with Chancellor Jeremy Hunt stating he won’t go “toe-to-toe” with America in a “distortive global subsidy race”. Instead, he said, he will focus on creating a “pro-growth regulatory regime”, which will be “different and better”. What that means, he promised, will be spelled out at his forthcoming autumn statement.

As an American who has lived and worked in London for the past 26 years, I have become accustomed to the British way of doing things. If in America the squeaky wheel gets the grease, then in the UK the tallest poppy is sure to be cut down. Which is to say the Chancellor has a point. There is no use in, nor any need for, the UK to go toe-to-toe in a subsidies war with America. Firstly, even in the best of economic circumstances it will never win; but secondly, and more importantly, the UK’s long term, disciplined approach to driving climate action while preserving energy security has resulted in a regulatory rulebook rich with opportunity to make Britain a clean energy powerhouse if we choose to make it so.

Researchers from Imperial College London have estimated that if the UK is to claim that mantle it must unlock £80bn in clean energy infrastructure investment. According to the Climate Change Committee, a similar level of investment could deliver more than £1 trillion of economic value. Better still, Britain is bursting with potential projects in hydrogen, long duration energy storage and carbon removals to name a few, and by tweaking our existing regulatory rulebook we can make them a reality.

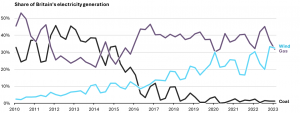

Take for example the Contract for Difference (CfD). While it will never grab headlines, it has helped Britain’s power system decarbonise faster than any other G7 nation. Expanding CfDs to new technologies like BECCS would enable companies like Drax get on an invest more than £2bn in BECCS technology here in the UK. The concept of a CfD is simple and has been used extensively in the generation of renewable power. Government enables upfront capital investment in large infrastructure projects by stabilising the revenue companies receive for the power these projects produce. If the market price of power is below the government stabilised level, companies receive the difference. If it is above, companies pay back. Being a private law contract, the CfD provides high levels of investor certainty while helping guard consumers against spikes in energy prices -delivering a public good that is a good deal for the public. According to think tank Onward, from November 2021 to January 2022, CfDs paid back £114 million to consumers – a figure that could rise as high as £10.5 billion per year by 2027.

Then there is our emissions trading system, or ETS. The UK was among the first nations in the world to put a price on carbon emissions back in 2002. Last year alone the Treasury netted over $1.4 billion from the UK’s ETS by charging emitters for every tonne of carbon dioxide from the atmosphere. In the coming months, Government will set out how it intends to reform the ETS, providing an opportunity to re-structure it with green infrastructure investment at its core. One option is to enable negative emissions to play a role inside the system by allowing companies to purchase credits from companies that remove carbon dioxide instead of simply paying government to emit. Doing so would mean meeting our climate change targets more efficiently and more affordably, while creating and sustaining thousands of British jobs.

Britain’s strategic advantage rests in 15 years of political consensus that tackling climate change can both benefit our planet and our economy. The Climate Change Act of 2008, which put in place legally binding carbon reduction targets, passed in the House of Commons with near unanimity. Since then, successive governments have introduced progressive law and regulation such as the CfD and ETS to reduce Britain’s emissions while keeping our economy growing and our energy supplies secure.

Across the Atlantic, however, America has been unable to develop the same policy options – held back by a deep-seated political divide on climate change and a seemingly inseverable relationship with fossil fuels. The Inflation Reduction Act has the potential to change that. When Joe Biden spoke on the South Lawn of the White House, he was keen to position the law as something more than just a package of subsidies. For him, it is a fundamental restatement of what matters to modern America: “Today offers proof that the soul of America is vibrant, the future of America is bright, and the promise of America is real.”

In Britain, tackling climate change has always mattered. We’ve literally written the rulebook on it. With America now at the table, the question for the UK is, can we write the next chapter in time?