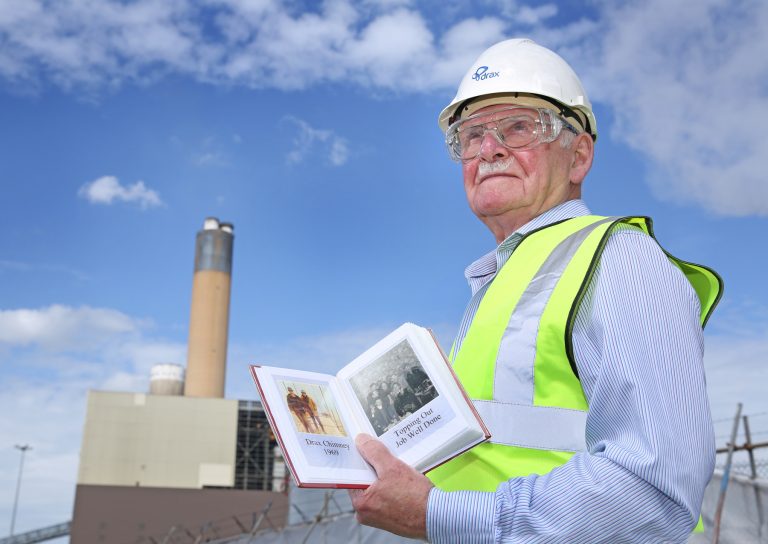

Harry Shann, now 83, was part of the team who worked at Drax Power Station 50 years ago constructing the 850ft high chimney, which has three flues linked to the site’s six generating units, four of which now run on sustainable biomass instead of coal.

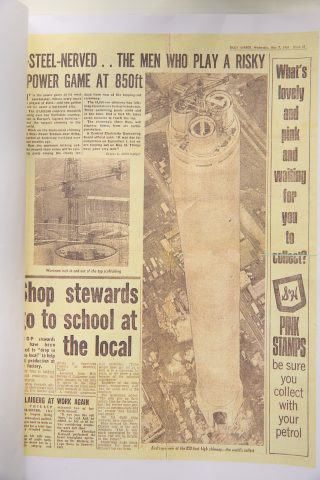

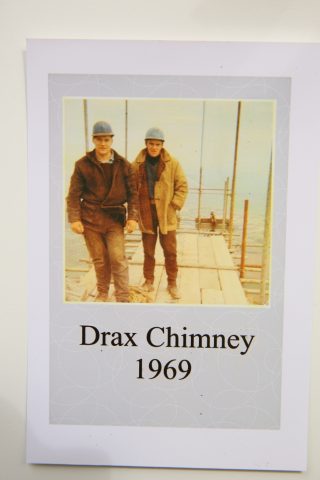

The chimney took just four months to build after work started in early 1969 and was completed four months ahead of schedule by a team of around 30 workers, with the topping out ceremony held in May to celebrate its completion.

Now, Harry, who was just 33 when he joined the project and still lives locally in Selby, has spent time back at the Drax site to reflect on his involvement in the record-breaking construction project.

He said:

“I still see it pretty much every day. It was definitely the highest build I ever worked on.

“I’m very proud of it, even after all these years, and I can still remember the time I spent on site. Considering the size of it though, we weren’t there long. We really got a move on.”

Due to the height of the structure, reaching the top can only be achieved by an eight-minute journey in an industrial lift or by scaling the 1,460 steps spiralling up the central void of the chimney.

Views from the top can stretch as far as the Humber Bridge more than 30 miles away on a clear day – and Harry admits it was only a job for those who were comfortable working high above the ground.

“I just never had a fear of heights. I was in the Parachute Regiment before I became a scaffolder, so that might have had something to do with it,”

the octogenarian said on his return visit to view the huge structure he helped to create.

“Being back at Drax Power Station, I realise just how much it’s changed. When I worked here, looking down from the chimney the area was bare, with hardly any buildings. Now it’s just amazing, it’s a wonderful site and I feel proud that the chimney is still standing 50 years later.”

The North Yorkshire power station, which first began generating electricity in 1974 when the first of its six generating units was commissioned, now produces enough electricity to supply five per cent of the UK’s power and is the biggest decarbonisation project in Europe.

Drax Power CEO Andy Koss said:

“Harry’s efforts, along with his colleagues’, in building such an important and iconic part of the power station are an integral part of Drax’s history and ongoing success.

“50 years on it is still the tallest industrial chimney in the UK – in many ways its completion marked the start of a rich heritage for engineering excellence and innovation at Drax, which has continued to the present day.”

Earlier this year, Drax confirmed that its groundbreaking trial of bioenergy carbon capture and storage (BECCS), using technology developed by Leeds-based C-Capture, had become the first project of its kind in the world to capture CO2 from a 100% biomass feedstock.

Drax has converted two-thirds of its generating units at the site near Selby to use sustainable biomass instead of coal transforming the business to become the largest renewable power generator in the UK.

ENDS

Chimney facts:

Drax chimney’s foundations are 70ft-deep.

The 44,000 tonne chimney cost around £1.5 million to build in 1969, the equivalent to £30 million today.

It’s almost twice the height of the Great Pyramid of Giza.

The record for the highest chimney in the world belongs to the Gres-2 Power Station in Kazakhstan. Built in 1987, it stands 1,377ft (420m) tall.

Media contacts:

Mark Duffell

MCD Communications Ltd

E: mduffell@mcdco.uk

T: 07969080272

Jessica Gorton

Drax Group Press Officer

E: jessica.gorton@drax.com

T: 07712677177

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

B2B supply:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com