Diane Nicholls, Vice President of Sustainability for North America, Drax

Key takeaways:

- British Columbia is 94% provincial Crown Land, meaning its 55-60 million hectares of forest cover is publicly owned, rather than privately held.

- Government legislation and regulation exists detailing what forestry practises can take place, working alongside First Nations, to ensure forests are used for the benefit of all.

- Sustainable forest management practises offer a source of fibre for forest industries while also protecting forests from disease and wildfire.

- Although the biomass pellet industry is relatively new to the province, it offers a use for forest residues that were previously burned or landfilled, and for sawmill residues.

As a business operating in the Canadian forest industry, we have a responsibility to work collaboratively with local and national governments, communities, and First Nations to ensure British Columbia’s forests are sustainably managed, protected from disease and fire, and preserved for future generations.

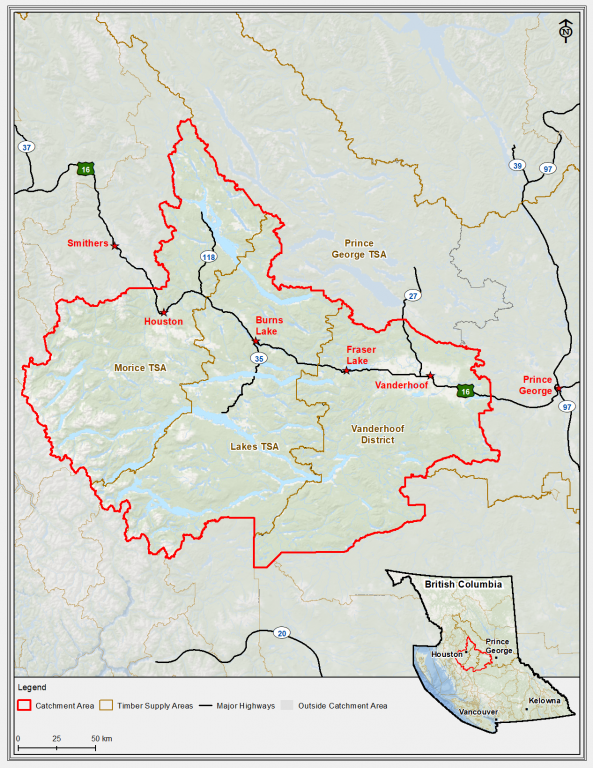

British Columbia is a vast and diverse landscape. The second largest of Canada’s provinces, it contains 14 different bio geoclimatic zones ranging from coastal forest in the west, to alpine meadows on the eastern Rocky Mountains, with bogs, wetlands, and even arid land in between.

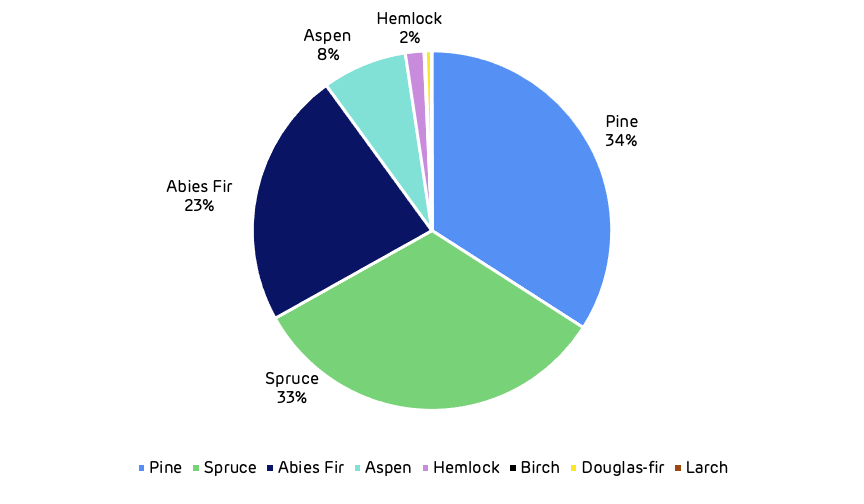

The landscape of British Colombia is home to a wide range of flora and fauna. With roughly 55-60 million hectares (550,000-600,000 km2) of land covered in forest, it is a vital resource. More than 50,000 British Columbians work directly in the forest industry and even as cities like Vancouver and Victoria grow, it remains a central source of social value to rural economies.

Sharing forests between government and First Nations

British Columbia has a long history of stewardship and sustainable forest management practices. Forestry began in the region in the 1800s with Sitka spruce, harvested predominantly to support ship building. Since then, forestry has become a major part of the province’s economy and the province is a world leader in sustainable forest management and environmental practises.

As 94% of British Columbia is provincial Crown Land, the government sets the rules and regulations about what forestry practices, or any other natural resource extractions, can take place. Under legislation, any land where forest harvesting occurs must be reforested and it is illegal for a company to deforest British Columbia or Canada.

For many years, an increasingly important component of the Canadian forestry industry has been the contribution that First Nations are making. There are 204 First Nations across British Columbia each with traditional territories used for cultural and spiritual purposes, as well as day-to-day needs like hunting, fishing, trapping, and housing.

Many First Nations have their own land use plans that are utilised in forest management planning in the province. First Nations are also consulted and collaborated with by the province on forest management decisions. This creates partnerships between First Nations, industries working in the province’s forests, and governments at the provincial and federal levels.

Protecting forests from pests and fire

Forest infected with mountain pine beetle in British Columbia

Managing forests is crucial to their longevity and ensuring they remain healthy and useable for future generations. This includes forestry practices to protect them from pests and the growing threat of forest fires.

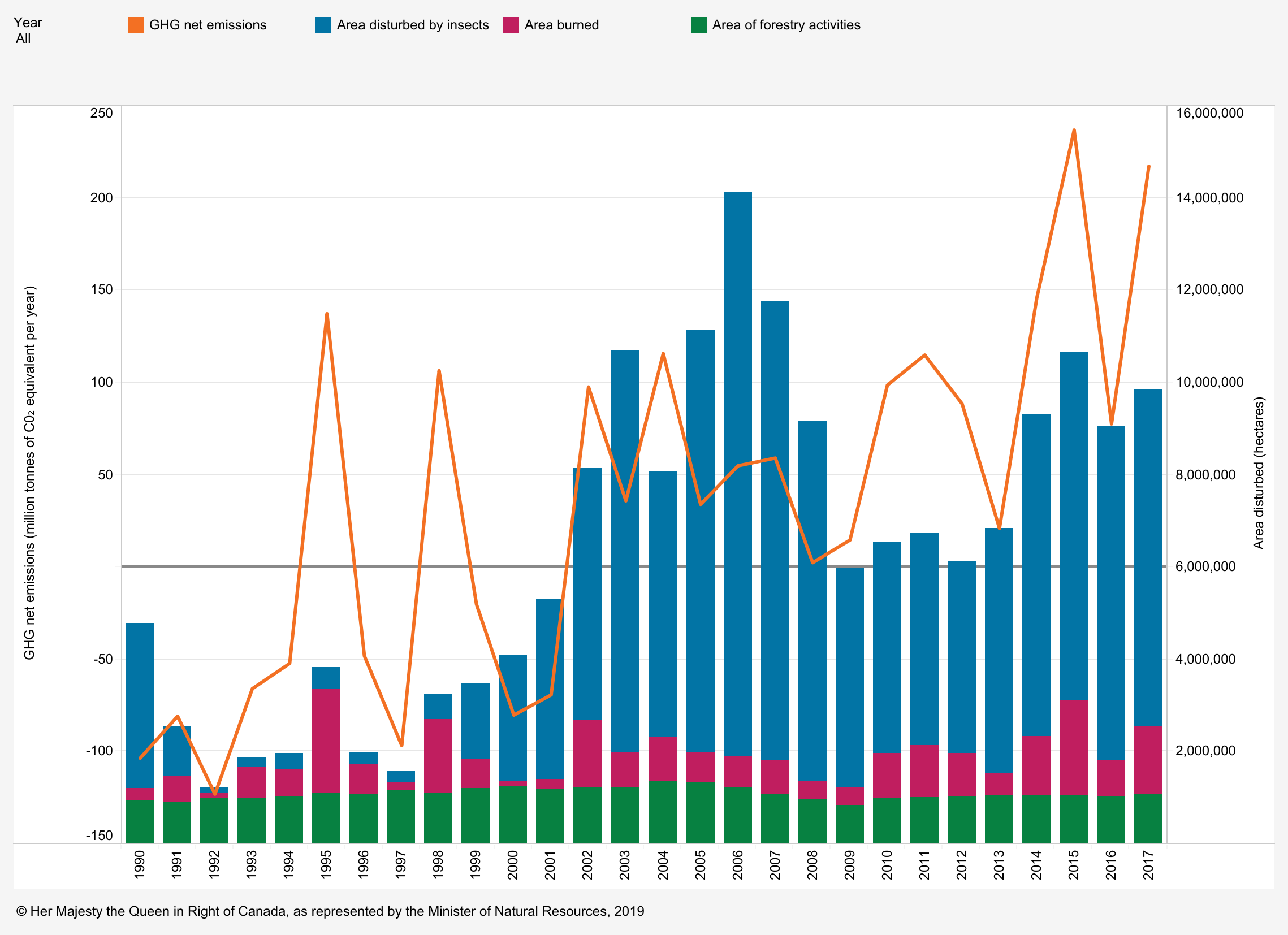

In 2017 and 2019 we saw the largest catastrophic fires we’ve ever had in British Columbia. At times it felt like the whole province was on fire. More recently, 2020 was another terrible year. Factors like climate change and storms are increasing the number of fires we see, but the intensity of fires is also exacerbated by debris left on forest floors from relatively recent mountain pine beetle infestations and other insects or diseases affecting forest health.

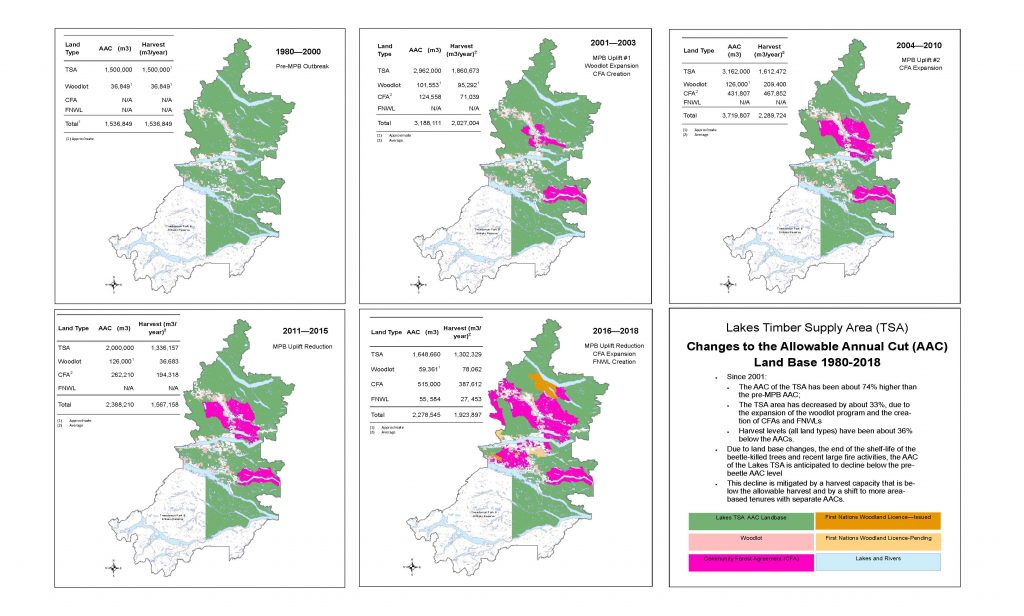

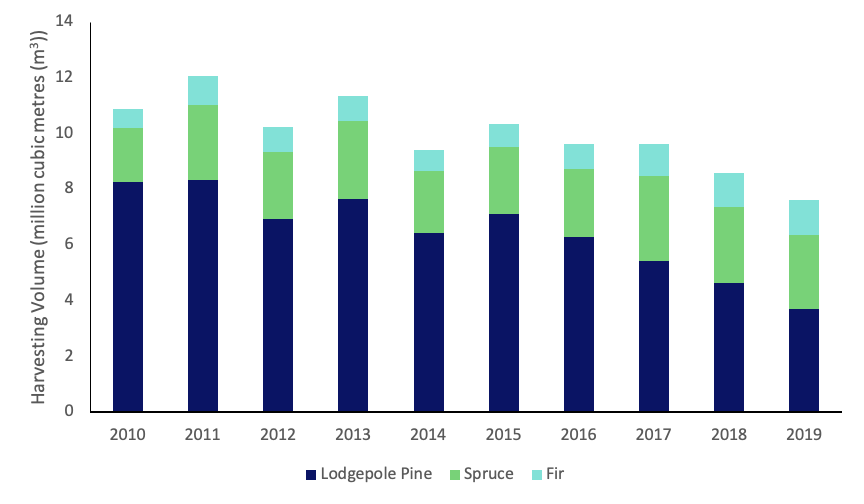

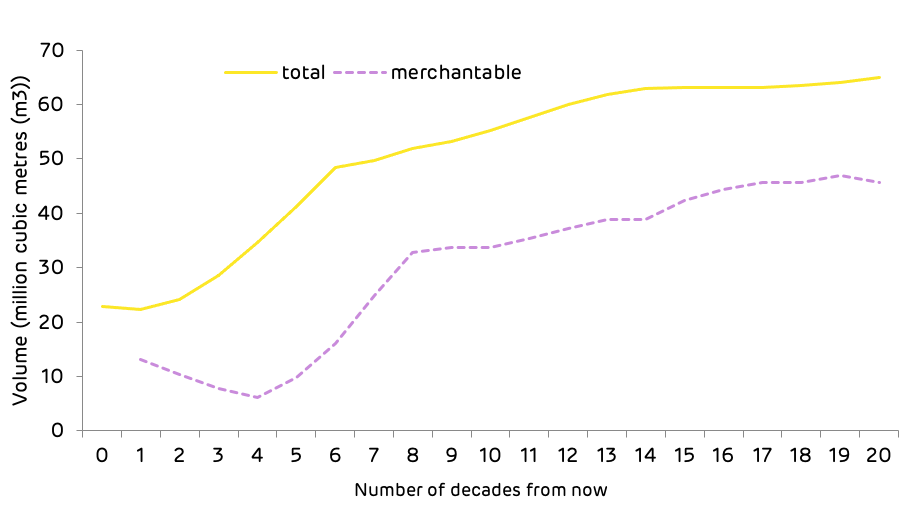

In the 1990’s several relatively warm winters led to the mountain pine beetle becoming endemic, and over the next 15 years millions of hectares of pine forest were lost to the bug. The government increased the allowable annual cut (harvesting levels) to remove the debris of such infestations which become dangerous fire hazards if not removed.

To protect from fires, pests, and diseases, it’s important to open up forests through managed removals. This process creates more space and less dense stands of trees. It’s also crucial to reduce what’s left lying on the forest floor after forestry operations, while ensuring that the right wood is left to encourage biodiversity, soil health and habitat needs.

These sustainable management practises are important to help the resilience of the forest and biomass offers a use for much of the wood removed through these practices that is not able to be manufactured into lumber.

Biomass and the wood industry

Compared to lumber manufacturing, pellet production is relatively new to British Columbia’s forest industry, but it offers a practical use for materials that are unmerchantable or unsuitable for sawlogs. This includes, but is not limited to, forms of forest residues such as low-grade wood, treetops, and branches that are left behind from harvesting activities.

Removing forest residues can provide more growing sites for new seedlings and helps to prevent intense forest fires. Slash and other low-grade wood are often simply burned along roadsides, but pellets offer a way to turn this fibre into a source of renewable energy.

Forest residues from harvests, like slash and low-grade roundwood, accounted for approximately 8% and 10% of the fibre used in our Canadian pellet plants in the first half of 2022. The rest of the fibre we use comes from sawmill residues, such as wood chips, shavings, and sawdust.

Drax operates eight pellet mills across British Columbia and two in neighbouring Alberta, but doesn’t own forests or carry out harvesting or wood sorting. Instead, we partner with forest companies that operate sawmills. These companies are awarded forest tenures, which allow them to harvest certain forest areas (which are identified by the provincial government) to produce solid wood products, which lock in carbon for years. In return, we obtain their sawmill residues. The economics of the wood pellet industry means the main driver of harvesting is still demand for high-grade timber.

Through collaboration with our partners across the province, we help ensure British Columbia’s forests offer resources that benefit local communities and are sustainably managed for future generations.